4 Stroke 3 Cylinder Petrol Engine Test With DAQ

Order Code: 32739

Category: Technology Trainers

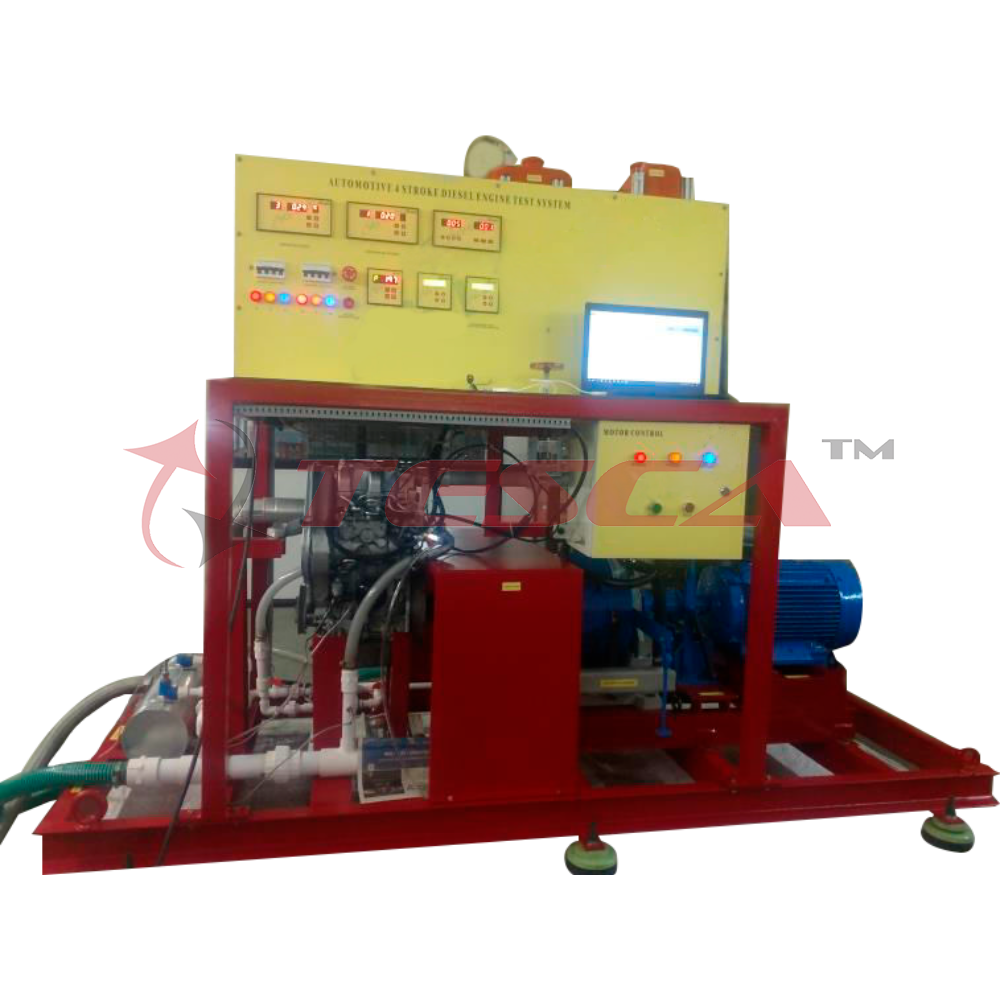

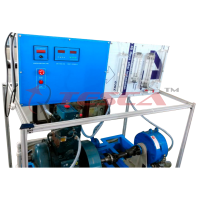

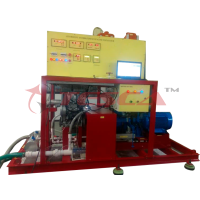

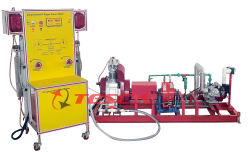

Tesca Automotive 4 Stroke 3 or 4 Cylinder Petrol Engine Test Bed 32739-32740 are designed to felicitate testing of different automobile petrol engines. The test bed is complete with eddy current dynamometer and measuring instruments for measuring key

SPECIFICATION

Features

- Designed for comprehensive analysis of performance of different automobile engines.

- Digital Instruments for measurement of parameters like fuel consumption, air flow, temperature and RPM etc.

- Demonstration of performance of Petrol Engines at different throttle settings & Loads.

- Optional High Speed Data Acquisition system for performance monitoring.

Tesca Automotive 4 Stroke 3 or 4 Cylinder Petrol Engine Test Bed 32739-32740 are designed to felicitate testing of different automobile petrol engines. The test bed is complete with eddy current dynamometer and measuring instruments for measuring key engine parameters required for performance analysis of an engine. The test bed can be used for testing of petrol engines of passenger cars, rated up to 80 kW.

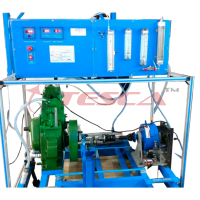

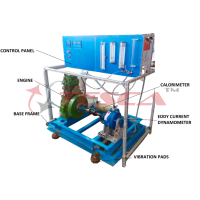

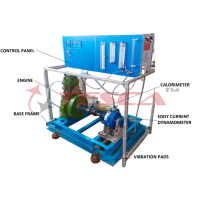

The test bed consists of a water cooled eddy current dynamometer fixed on a heavy-duty steel frame. The test bed is designed in such a way that the engine to be tested can be quickly coupled to the dynamometer with minimum effort. The test bed is equipped with dynamometer control panel with necessary safety instruments. The Engines can be used for performance tests for different loads and speeds under various throttle opening conditions. The eddy current dynamometer provides a variable load on the engine, allowing the characteristic power and torque curves to be reproduced in the laboratory. The system comes complete with extensive instrumentation, including rpm measurement, torque (from which power can be calculated), plus various temperatures, Fuel Consumption, Air Consumption.

Different optional accessories are available to integrate with the Engine Test Bed for comprehensive

engine performance analysis. These include the exhaust gas calorimeter (For Heat Balance Sheet),

advance Data Acquisition System & P-V Diagram module for computerized testing.

Specifications

Dynamometer:

- Water Brake Dynamometer:

- Maximum power : ± 75 kW

- Maximum Torque : ± 90 Nm

- Maximum speed : ± 14,000 rpm- continuous

- Water Inlet : ± 38 Lpm - low facility water consumption

- Water brake type of absorption that shall enable for long run testing without dropping the performance of the Dynamometer.

- Capable test both vertical and horizontal output shaft engines

- Construction: High strength aluminum alloy shaft: Hardened stainless steel

- Bearings: Greased ball & roller

- Torque sensor: Strain gauge load cell

- Speed sensor : 60 tooth wheel with inductive pulse pickup.

- Set of Weighing System comprises of calibration arm, weight open assembly and calibration weights.

Dynamometer Controller

- Manual Load control valve for Dynamometer

- Designed for users to manually control the dynamometer

- The valve unit is connected to the dynamometer water supply. It incorporates two industrial-quality valves in a compact parallel configuration to maximize control throughout the dynamometer testing range

- System include large globe throttling valve for course –load adjustment and a small needle valve for fine-load adjustment.

- Each valve has a billet- aluminum knob with knurled edge for ease of operation.

- Engine: Portable engine test bed come with flexible coupling

- Gasoline/petrol engine:

- 660c Natural Aspirated Gasoline Engine or better

- In-Line 3 Cylinder

- 4- Stroke

- SOHC

- (Note: Additional Engines can be supplied on request.)

- Air Box with Orifice plate for Air flow measurement.

- Fuel Tank: 1 Tank each for Petrol.

- Propeller shaft with protective covering.

- Digital Measuring Instruments Console –

- Engine RPM Sensor

- Differential Pressure Transmitter for Air

- Fuel Level Sensor

- Thermocouples

- Torque Sensor

- Fuel Flow Rate

Accessories:

Manual Engine Throttle Actuator

Battery and Isolator Box

Engine Exhaust Piping

Fuel tank supply to the engine fuel intake

Battery for starting the engines

Set of Anti Vibration Pads

Auxiliary cooling unit for engine

Radiator Cooling System for Engine Coolant temperature control purposes

Exhaust Gas Calorimeter (Optional)

Cooling Water Flow Transmitter

Pipe In pipe type heat exchanger

Thermocouples for water & gas temperature.

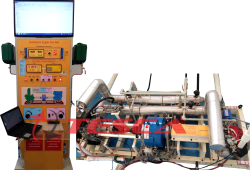

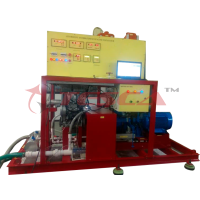

Data Acquisition System & Software (Optional)

Signal Converter

Data Acquisition Card, 16 Channel High speed DAQ Card with USB Port

Software: Labview based software for data acquisition, real time display, graphical representation, calculation & tabular results.

Computer interface & DAQ software can be offered:

High Speed DAC with 1 mega samples/sec

Fuel injection System with controls

Software: Engine Combustion Analysis and performance

Software, Fuel injection and control software.

Sensors:

a) Engine Combustion Pressure Sensor: Piezo-electric 0-100 Bar

b) Crank angle: Rotary 360 PPR

c) Air Measurement: DP Sensor

d) Fuel Measurement: Optical constant volume, fully automatic

e) Speed: Encoder

P-V Diagram Module (Optional)

Engine cylinder pressure

Crank angle Encoder

Experiments

- Investigate Engine Performance at different Throttle Settings & Load conditions.

- Calculation of Mechanical Efficiency & Plot brake power versus mechanical efficiency.

- Measurement & Calculation of Volumetric efficiency.

- Measurement & Calculation of specific fuel consumption

- Measurement & Calculation of brake thermal efficiency

- Determining air / fuel ratios

- Heat Balance Test (With Optional Exhaust Gas Calorimeter)

- Study of P-q & P – V Diagram for Engine (With optional P-V Module & Data Acquisition System).

Scope of Delivery

- 1 engine, complete with all connections and supply lines

- 5 combustion chamber inserts

- One set of tools

- 1 manual

91-9829132777

91-9829132777