Advanced Customized Electro-hydraulic Trainer

Order Code: 52293

Category: Process Control Trainers

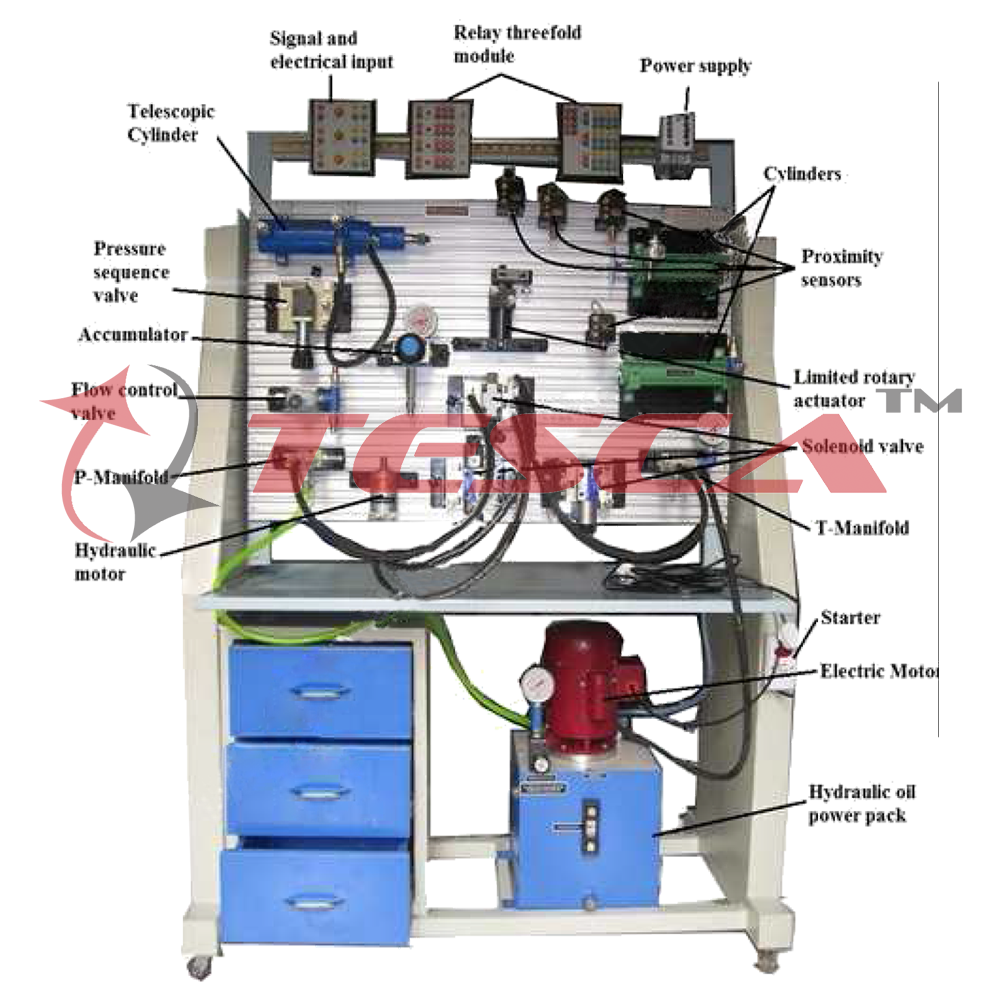

The Advanced customized Electro-Hydraulic Trainer (52293) is capable of being used to demonstrate the design, construction and application of electro-hydraulic components and circuits. The components are capable of being mounted on an appropriate pr...

SPECIFICATION

The Advanced customized Electro-Hydraulic Trainer (52293) is capable of being used to demonstrate the design, construction and application of electro-hydraulic components and circuits.

The components are capable of being mounted on an appropriate profile plate with grooves for secure and flexible positioning so that the components can be clamped firmly, quickly and safely through quick fix adaptors.

Industrial components are used in the kit so that the students get hands on practical training in using industrial components.

Objectives

- Function & identification of Electro-Hydraulic components & their symbols.

- Direct and indirect manual controls, stroke dependant controls and pressure dependant controls with pressure sequence valves.

- Design & function of a electro-hydraulic System.

- Functional diagrams.

- Application and fault findings of Electro Hydraulic controls.

- To empower students to design their own circuits.

- The Trainer is Modular & Upgradable

- Operation & Instruction Manual provided for Operation ease.

Features

- Compact Ergonomic Design.

- ISO Symbol for each mounted components

- User Friendly, Self Explanatory Systems.

- Leak proof Safety Measures, sturdy piping & Robust Construction.

- Training Manuals mimic Charts for Operation Ease.

- System Frame with Caster Wheel Arrangement for ease in movement.

- Inbuilt Safety Measures to avoid improper usage.

- Wall mounting assemblies of hydraulic actuator & self-reciprocating cylinder.

- Solenoid Valves (electro-hydraulic), Limit Switches (Optional )

- Proximity type sensors (electro-hydraulic),

- QRC Couplings provided Tubing /hose pipes for circulation of pressure.

- Manifold for distribution.

- Oil Hydraulic power pack for power supply.

- Optional components are available to allow fault operation and diagnosis training.

- Training literature – Instruction & operation manual , troubleshooting & maintenance tips will be provided in soft copy as well as hard copy format

Range of experiments

01. Study of pressure control

02. Study of direction control.

03. Study of fundamental principles of Hydraulics & its applications.

04. Study of Meter-in circuit, Meter-out circuit and Bleed-off circuit.

05. Study of flow control.

06. Study of Hydraulic Valves

07. Study of cylinder control.

08. Study of Non return Valve

09. Study of Pilot operated check valve

10. Study of power pack control characteristics.

11. Study of electro-hydraulic control.

12. Study of sequencing of two cylinders using sequence valve.

13. Study of sequencing operation of two cylinders using electro-hydraulic components.

91-9829132777

91-9829132777