Axial Flow Turbo Machines

Order Code: 32084

Category: Fluid Mechanics Lab

Features: Investigation of a single-stage axial turbo- machine 1 Can be operated as pump or turbine by changing the paddels1 Transparent working area The core piece of the experimental plant is the Tesca Axial ...

SPECIFICATION

Features:

Investigation of a single-stage axial turbo- machine 1

Can be operated as pump or turbine by changing the paddels1

Transparent working area

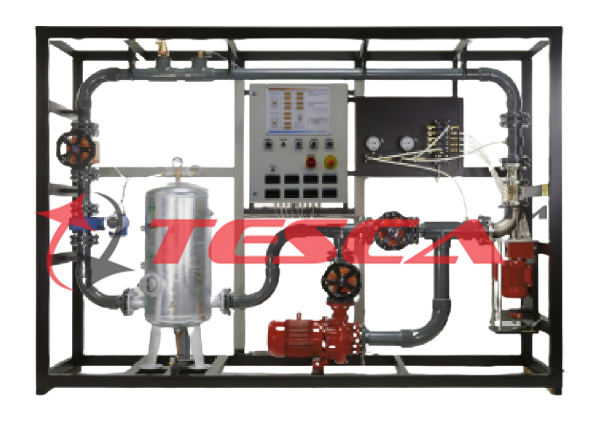

The core piece of the experimental plant is the Tesca Axial Turbo-machine with an attached motor/generator. It can be operated either as a pump or turbine. To this end, different sets of paddles are used. The transparent housing allows a full view of the blades and flow processes. A compressed- air- powered equalization basin can quickly flood the system. Operation under different pressure levels is possible in order to study the cavitation. The braking power is fed back into the grid.

A water tank allows the turbo-machine to be converted without loss of water. In turbine mode, the turbo-machine is driven by means of a powerful pump. The extra rotors and stators supplied with different blade angles allow sophisticated experiments. Velocity triangles can be used for the graphical representation of the velocity conditions at the water inlet and outlet as well as within the turbo-machine.

The speed is detected contact-free by means of an inductive displacement sensor on the motor shaft. To determine the drive power, the drive

motor is mounted on swivel bearings and equipped with a force sensor to measure the drive torque. The differential pressure is detected radially in different blade planes by means of a 3-hole probe. Manometers measure the inlet and outlet pressures. The flow rate is measured by an electromagnetic flow meter. The measured values are read from digital displays.

The experimental plant contains a closed water circuit with a tank and centrifugal pump.

The well-structured instructional material sets out the fundamentals and provides a step-by- step guide through the experiments.

Specifications

Investigation on an axial flow turbo-machine

Closed water circuit with tank and centrifugal pump

Turbo-machine may be operated as a turbine and as a pump

Two sets of paddles for pump mode and two sets of paddles for turbine mode with different entry and exit angles

Asynchronous motor/generator with 4- quadrant operation via frequency converter

Regenerative feedback of the brake energy

Motor with pendulum bearing, torque measurement via lever arm and force sensor

Inductive speed sensor on the motor

Manometer for measuring the inlet and outlet pressures

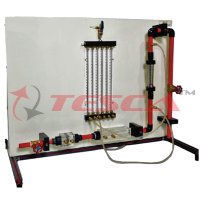

Measuring probe and differential pressure sensor for recording the pressure curve in the turbo-machine

Electromagnetic flowmeter

Display of power consumption, torque, speed, pressure, differential pressure, and flow rate

Technical Specifications:

Centrifugal pump

Power: 5,5kW

Max. flow rate: 150m³/h

Max. head: 10m

Motor/generator

Power: 1,5kW

Torque: 0...5Nm

- Speed: 0...3000min-1

Water tank: 150L

Measuring ranges

Pressure (manometer): 2x -1...5bar

Differential pressure: 5x 0...500mbar

Flow rate: 0...150m³/h

- Speed: 0...9999min-1

Torque: 0...5Nm

Experiments:

Recording characteristic curves

Determining dimensionless characteristics

Velocity triangles and pressure curves

Investigation of energy conversion within the turbo-machine

How blade shape affects power and efficiency

Determine the outlet angular momentum and its effect on the power

Cavitation effects

Services Required:

Mains power supply: 220-240V, 1Ph, 50Hz

Compressed air connection: 3...10bar

91-9829132777

91-9829132777