Deformation of frames

Order Code: 32158

Category: Strength of Materials Lab

Features Elastic deformation of a statically determinate or indeterminate frame under point load U-shaped and S-shaped frame Principle of virtual work to calculate the deformation and support reaction in a statically indet...

SPECIFICATION

Features

- Elastic deformation of a statically determinate or indeterminate frame under point load

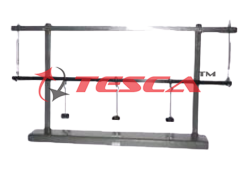

- U-shaped and S-shaped frame

- Principle of virtual work to calculate the deformation and support reaction in a statically indeterminate system

A frame is a bent beam with rigid corners which creates a so-called structure gauge. This means that it spans a gap while at the same time creating height.

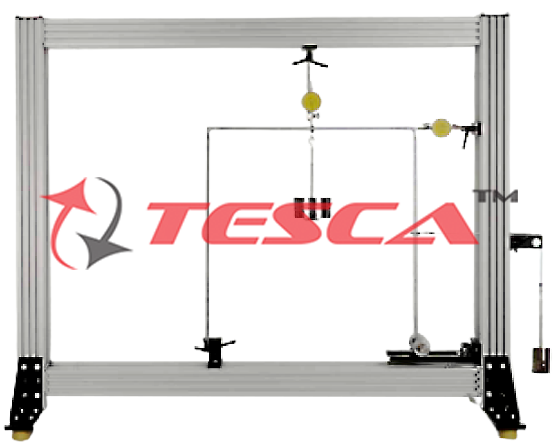

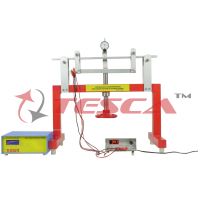

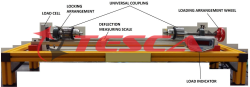

Tesca Deformation of Frames includes a typical U-shaped frame, such as is used in the construction of halls for example. One end is clamped into place, while the other can be loosely mounted. When the non-clamped end remains free, the statically determinate frame is investigated. A roller bearing on the non-clamped end creates a statically indeterminate frame. The frame is placed under load by two sets of weights. The load application points are movable. Two dial gauges record the deformations of the frame under load.

By applying various methods (first-order elasticity theory; the principle of superposition; and the principle of virtual work), the bending moment characteristics are ascertained for a statically determinate and indeterminate frame. From these characteristic curves and a chart for integrals (coupling table) the differential equation of the bend line is formulated. From the bend line and its derivations, displacements and the support force on the movable support can be calculated. A second, S-shaped frame can be used to show that the various methods are applicable to any kind of frame. All the component elements of the experiment are clearly laid-out and housed securely in a storage system.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specifications

Investigation of the deformation of steel frames under load

U-shaped and S-shaped frame

Statically determinate or statically indeterminate bearing support possible

1 long and 1 short clamping pillar

Roller bearing for statically indeterminate support

Loading of the frame by weights

2 sets of weights with a movable hook to adjust to any load application point

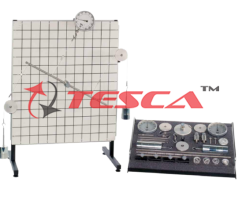

Dial gauges record the deformation of the investigated frame under load

Storage system to house the components

Technical Specifications

Frame made of steel

- Edge length: 600mm

- Cross-section: 20x10mm

- U-shaped: 600x600mm

- S-shaped: 600x600mm

Dial gauges

- Measuring range: 0...20mm, graduations: 0,01mm

Weights

- 2x 1N (hanger)

- 8x 1N

- 6x 5N

Experiments

Relationship between load application and deformation on the frame

Differences between statically determinate and statically indeterminate frames

Familiarisation with the first-order elasticity theory for statically determinate and indeterminate systems

Application of the principle of superposition

Application of the principle of virtual work on statically determinate and statically indeterminate frames

- Determination of a deformation by the principle of virtual forces

- Determination of a load by the principle of virtual displacement

Comparison of calculated and measured deformations

Scope of Delivery

- 2 frames (1x U-shaped, 1x S-shaped)

- 2 clamping pillars (1x long, 1x short)

- 1 support

- 2 sets of weights with movable hooks

- 1 deflection roller with fixture

- 1 cable

- 2 dial gauges with bracket

- 1 storage system with foam inlay

- 1 set of instructional material

91-9829132777

91-9829132777