HMP™ U-Coupling (Taper Pipe Coupling)

Order Code: HMP™ U

Category: Pipe Jointing Couplings

OVERVIEW Overview: The HMP™ U-Coupling is a high pressure pipe coupling designed as an easy method of joining pipes. Sometimes referred to as a quick couplings for steel pipes, the U-Couplings are used in medium to high pressure piping syste...

SPECIFICATION

OVERVIEW

Overview: The HMP™ U-Coupling is a high pressure pipe coupling designed as an easy method of joining pipes. Sometimes referred to as a quick couplings for steel pipes, the U-Couplings are used in medium to high pressure piping systems. It speeds up installation time drastically when compared to flanges. Using the HMP™ U-Coupling will result in lower capital expenditure, due to the fact that it is has a lower procurement cost, more pipes can be loaded per truck or rail carriage load, it takes less space when stored and most importantly, there will be a saving on labour, as installation is quicker and easier than flanges. It can be installed in vertical mine shafts, inclines or horizontally.

The HMP™ U-Coupling can be used in pipe lines carrying liquids or abrasive material and is perfect for mining backfill pipes. The HMP™ U-Coupling can be installed in a system where pipes hang on chains, parrot swings or are U-Bolted down onto pipe supports. Pipes shoul be anchored before and after every change of direction. The full range of HMP™ valves, expansion joints and energy dissipator can be manufactured with U-Coupling end connections.

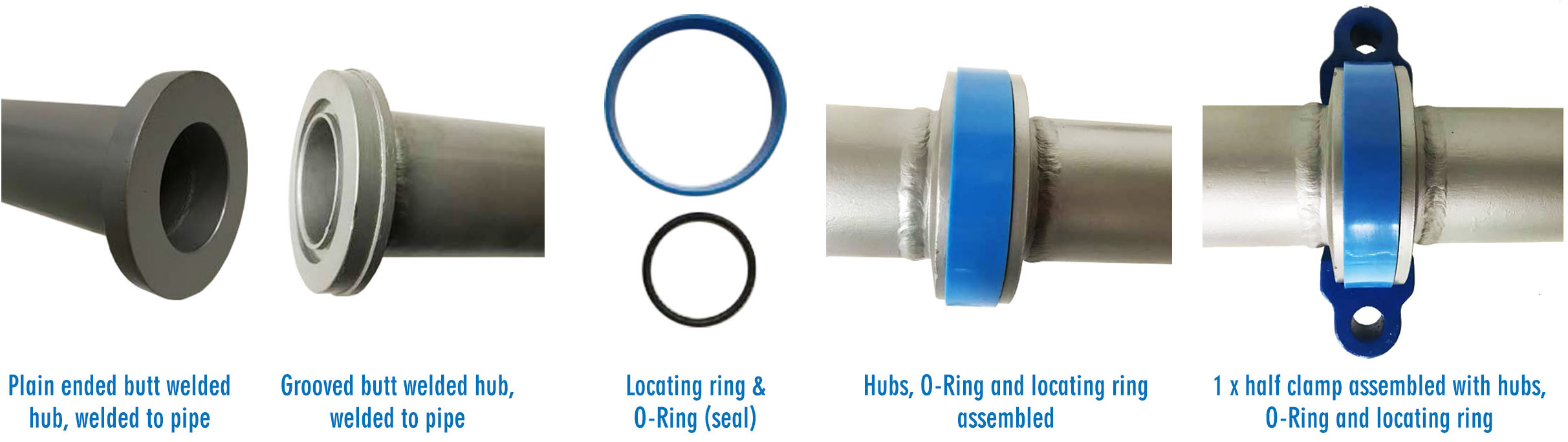

There are two types of HMP™ U-Coupling the first type is the "A" type which has two identical hubs. The "A" type can be used with a UHMWPE or PTFE compression seal. The "A" type does not require the use of an alignment ring as the seal aligns the pipe. Furthermore, the "A" is sexless which makes installation easier, especially on valves or pipe fitting. The second type, type "B" effects a seal using a nitrile or polyurethane O-ring. The "B" types hubs are slightly different, one side of the hub is grooved to accomodate the seal and the other hub has a flat surface which compresses the seal into the groove. It requires an alignment ring to ensure correct hub alignment. Care needs to be taken when installation is done as long length of pipes cannot be turned around in narrow spaces and underground tunnels.

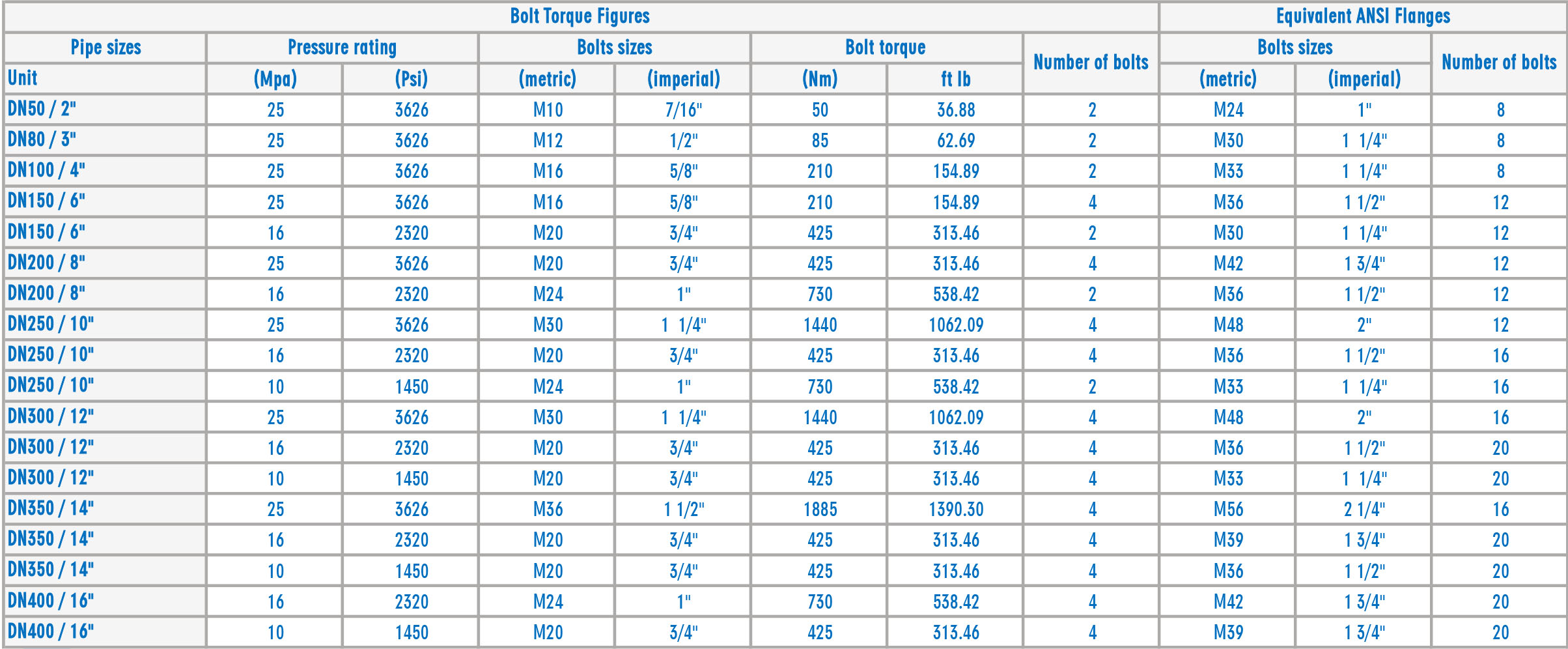

BOLT TORQUE SETTINGS

PARTS (TYPE A)

PARTS (TYPE B)

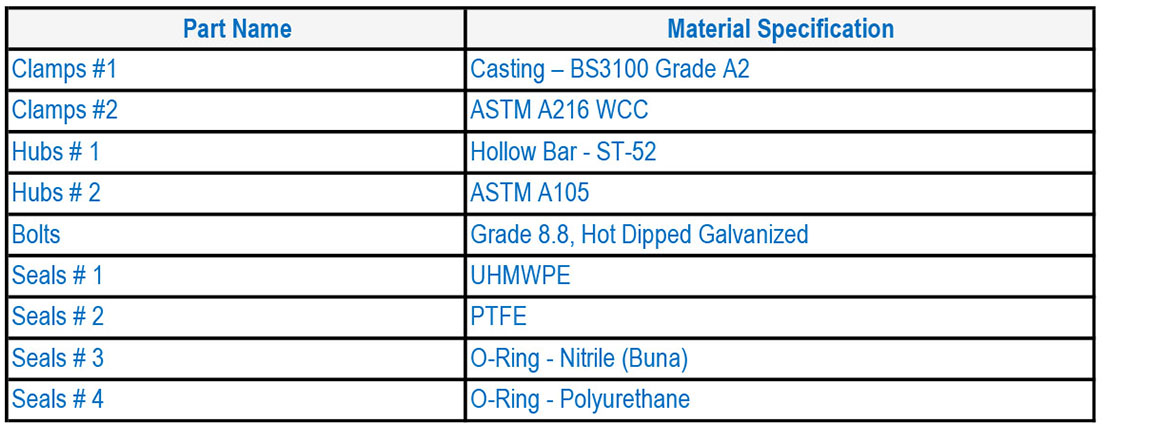

MATERIALS OF CONSTRUCTION

DESIGN AND MANUFACTURING STANDARDS

The HMP™ Hydraulic coupling are designed in accordance with various international standards as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.3

ANSI B16.34

ANSI N278.1

ANSI B16.37

Available sizes: DN50 / 2" to DN500 / 16"

Pressure rating: up to 25MPa / 3 626 psi

91-9829132777

91-9829132777