Heat Pump Trainer

Order Code: 32409

Category: Refrigeration & Air Conditioning Lab

System Feature Utilization of ambient heat for water heating Display of all relevant values at the location of measurement In the air-to-water heat pump Tesca Heat Pump Apparatus 32409 the ambient heat of the air is used to heat water. The heat p...

SPECIFICATION

System Feature

Utilization of ambient heat for water heating

Display of all relevant values at the location of measurement

In the air-to-water heat pump Tesca Heat Pump Apparatus 32409 the ambient heat of the air is used to heat water.

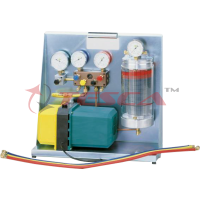

The heat pump circuit consists of a compressor, an evaporator with fan, a thermostatic expansion valve and a coaxial coil heat exchanger as condenser. All components are clearly arranged in the trainer.

The compressed refrigerant vapour condenses in the outer pipe of the condenser and thereby discharges heat to the water in the inner pipe. The liquid refrigerant evaporates at low pressure in the finned tube evaporator and thereby absorbs heat from the ambient air.

The hot water circuit consists of a tank, a pump and the condenser as heater. For a continuous operation the generated heat is dissipated via an external cooling water connection. The cooling water flow rate is set via a valve and measured.

All relevant measured values are recorded by sensors and displayed. The simultaneous transmission of the measurements to a data recording software enables analysis and the representation of the process in the log p-h diagram. The software also displays the key characteristics variables of the process, such as the compressor pressure ratio and the coefficient of performance.

Specifications

Investigation of a heat pump with a water circuit as load

Refrigeration circuit with compressor, evaporator with fan, thermostatic expansion valve and coaxial coil heat exchanger as condenser

Hot water circuit with pump, tank and condenser as heater

Additional cooling via pipe coil in the hot water tank and external cooling water

Record and display of all relevant measured values and

Software for data acquisition via USB under Windows 7, 8.1, 10

Technical Specifications

Compressor

- capacity: 372W at 7,2/32°C

Coaxial coil heat exchanger (condenser)

- Refrigerant content: 0,55L

- Water content: 0,3L

Finned tube evaporator

- Transfer area: approx. 0,175m2

Pump

- Max. flow rate: 1,9m3/h

- Max. head: 1,4m

Hot water tank volume: approx. 4,5L

Measuring ranges

- Pressure: 2x -1…15bar

- Temperature: 4x 0…100°C, 2x -100…100°C

- Power: 1x 0…6000W

- Flow rate: 1x 0…108L/h (water)

- Flow rate: 1x 10…160L/h (cooling water)

Additional Options

1. Computerised Heat Pump Trainer

An advanced personal computer based model. This system has facility of data acquisition, plotting on-line and historical trends. It carries out complete calculations to determine performance. A comprehensive HELP menu makes the system user friendly.

2. Heat Pump fault trainer.

Note: Details of attachments can be made available on request.

Optional Accessories

Gas charging unit

HP/LP Cutout

Tool kit

Cut away model of refrigeration components.

Experiments

- Design and operation of an air-to-water heat pump

- Representation of the thermodynamic cycle in the log p-h diagram

- Energy balances

- Determination of important characteristic variables

- Compressor pressure ratio

- Ideal coefficient of performance

- Real coefficient of performance

- Dependence of the real coefficient of performance on the temperature difference (air-to-water)

- Operating behavior under load Study PLC Interface (Optional).

Services Required

- Electrical Supply, 220-240 V Single-phase.

- Water supply and drainage arrangement

91-9829132777

91-9829132777