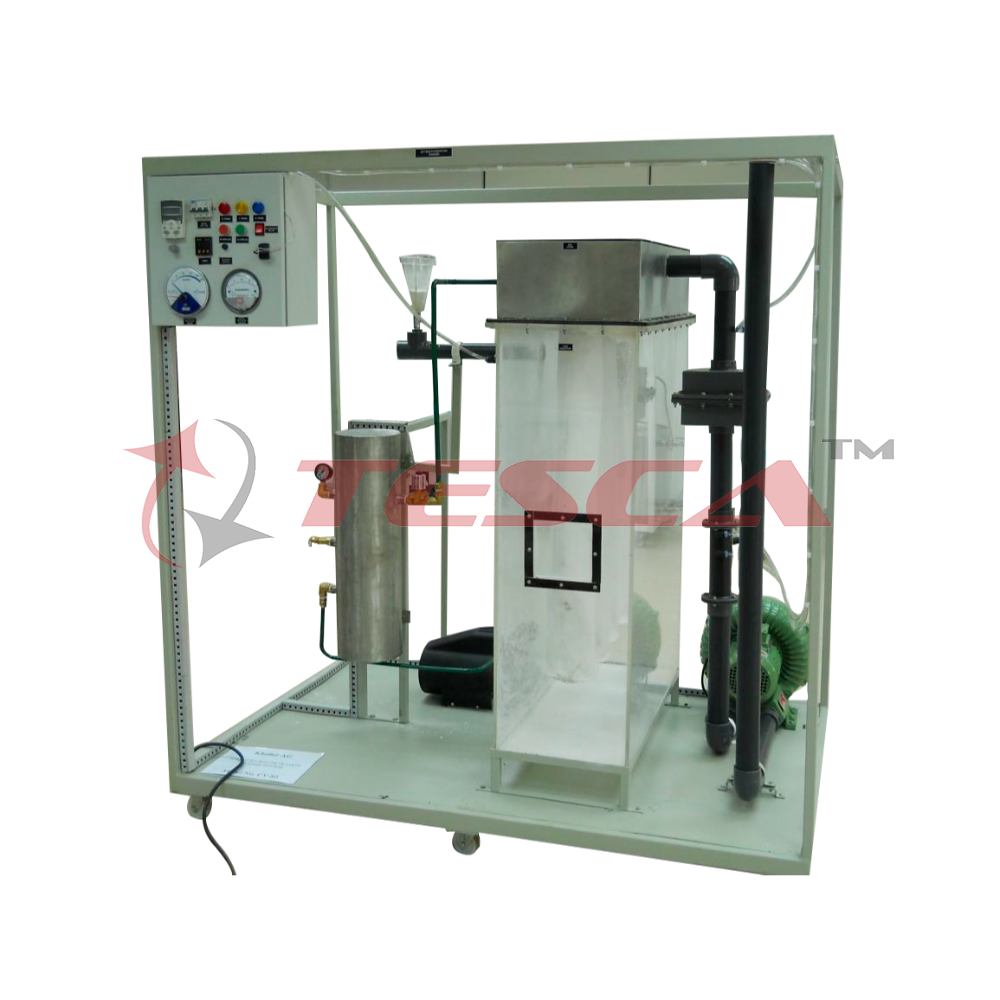

Pulsed - Jet Filtration Training System

Order Code: 32476

Category: Environmental Trainers

Tesca Pulsed - Jet Filtration Training System 32476 has been designed for demonstrating dust pollution control using a fabric filter and for investigating the effects of varying total filtration area on filtering efficiency. In addition, students can...

SPECIFICATION

Tesca Pulsed - Jet Filtration Training System 32476 has been designed for demonstrating dust pollution control using a fabric filter and for investigating the effects of varying total filtration area on filtering efficiency. In addition, students can study the effects of varying gas-to-cloth (G/C) ratio between pressure drop, ΔP and inlet velocity, vi.

The system comprises of a bag house, a pulse-jet cleaning system, a dust feeding system and a variable speed air blower. The bag house is divided into two sections: top and bottom. The top section is of stainless steel construct, connected to the compressed air tank to form part of the pulse-jet cleaning mechanism. The bottom section is made of rigid transparent polycarbonate with dust collector. Through this bottom section, students can view the filtering and cleaning operations of the bag filtering system. The cleaning mechanismcomprises of a compressed air tank, a solenoid valve with remote selectable timer and a portable air compressor unit. Four units of polyester fabric filters are installed in a row inside the bottom section of the bag house. An air blower installed at the outlet is capable of drawing 198 m3/hr of air through the system. The air inlet velocity can be varied by means of adjusting the air blower

speed. A dust feeding system is provided for introducing a desired amount of dust particles into the air stream before entering the bag house. The pressure drop, ΔP across the bag house can be measured by a differential pressure meter. The entire system is mounted on a skid platform with an epoxy-coated steel frame and lockable castor wheels for mobility. All the necessary instruments are housed within a dust and splash proof control console with IP 55 rating. The system comes with complete PVC piping connections.

Experiments

- Demonstration of a bag filtering system in dust pollution control

- To study the effects of varying total filtering area

- To investigate the effects of varying gas-to-cloth (G/C) ratio on separation efficiency

- To verify the relationship between pressure drop, ΔP and inlet velocity, vi

Technical Specifications

a) Bag house

No. of sections : 2

1Top section material : Stainless steel

Dimensions : 890 mm (L) x 380 mm (W) x 200 mm (H)

Btm. section material : Clear polycarbonate

Accessories : Dust collector

b) Fabric filter

Material : Polyester

Dimensions : 13.5 cm (D) x 100 cm (H)

Mount : Support cage to prevent collapse

c) Pulse-jet cleaning system

Compressed air tank

Capacity : Approx. 20 L

Material : Stainless steel

Accessories : Pressure relieve valve 0 to 2 bar

Air compressor : Portable type 1 hp

Cleaning nozzles for each fabric filter

Solenoid valve with remote selectable timer

d) Air blower

Rated power : 2 hp

Max. air delivery : 198 m3/hr @ 2800 rpm

Max. static pressure : 69 in H2O

Speed controller : Frequency inverter

e) Air flow meter

Type : Venturi with differential pressure gauge

Material : Durable clear acrylic

DP gauge range : 0 to 16 in H2O

f) Feeding container

Material : Acrylic cylinder with conical bottom

Feed control : Rapid acting valve

g) Differential pressure

Type : Panel mounted Bourdon type differential pressure gauge

Range : 0 to 25 cm H2O

91-9829132777

91-9829132777