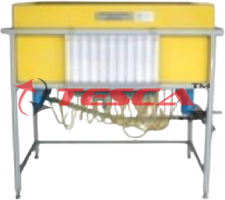

Turbine Set: Pelton, Francis, Kaplan

Order Code: 32098

Category: Fluid Mechanics Lab

Features : Comparison of impulse and reaction turbines1 Constant speeds and torques can be adjusted in combination Characteristics of a Kaplan turbine1 Adjustable guide vanes for setting the power output1 Water turbines...

SPECIFICATION

Features :

Comparison of impulse and reaction turbines1

Constant speeds and torques can be adjusted in combination

Characteristics of a Kaplan turbine1

Adjustable guide vanes for setting the power output1

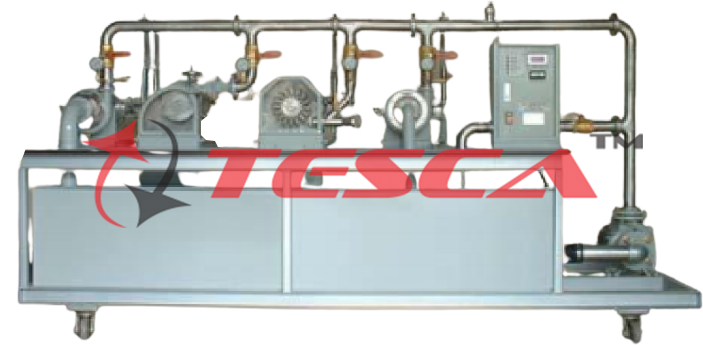

Water turbines are turbo-machines utilizing water power. They convert pressure and flow energy into mechanical energy and mostly are used for driving electrical generators. Water turbines can be divided into impulse and reaction turbines depending on their operating principle. Tesca Multi-Turbine: Pelton, Francis & Kaplan Turbines and Accessories contain a Pelton turbine as an example for an impulse turbine and a Francis turbine as an example for a reaction turbine. The two turbine types are examined and compared with each other together with the Turbine Supply Unit and the Universal Drive and Brake Unit. The drive unit offers the possibility to set constant speeds resp. torques. Thus you can realize experiments in different realistic operating modes.

The Pelton turbine is a free-jet turbine that converts the pressure energy of the water into kinetic energy entirely in the control device. As the complete pressure difference is reduced exclusively in the nozzle, the pressure is constant in the impeller. The turbine is also known as a constant pressure turbine. The turbine power is controlled by adjusting the nozzle cross-section.

The Francis turbine converts the pressure energy of the water into kinetic energy in the control device and in the impeller. The pressure at the wheel inlet is higher than at the wheel outlet. The turbine power is controlled by adjusting the vanes in the control device.

The Turbine Supply unit provides the water supply, the pressure measurement at the turbine inlet, and the flow rate measurement. In order to measure the pressure at the turbine outlet, the Francis turbine is equipped with an additional pressure sensor. Tesca Universal Brake and Drive Unit measures the braking torque and the speed.

The well-structured instructional material sets out the fundamentals and provides a step-by- step guide through the experiments.

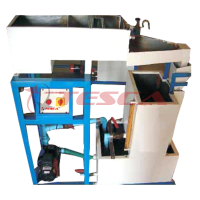

The Kaplan turbine is a reaction turbine with an axial through the flow. It has a high specific speed and is suitable for large water flows and small to medium heads. Therefore, the Kaplan turbine is used as a "classic" water turbine in run-of-the-river power stations.

Kaplan turbine helps to investigate the characteristic behavior of a simple-regulated Kaplan turbine during operation. The trainer is provided with a closed water circuit with a tank, submersible pump, and throttle valve for adjusting the flow rate. The angle of attack and thus the power output of the impeller is changed by adjusting the guide vanes. The turbine is loaded with a wear-free eddy current brake. The speed is captured by means of an inductive, non- contact position sensor at the turbine shaft. For determining the turbine power, the eddy current brake is equipped with a force sensor for torque measurement. The pressures at the inlet and outlet of the turbine, the temperature, and the flow rate are recorded with sensors. The recorded measured values are displayed digitally and processed further on a PC. The PC is used to calculate the power output data of the examined turbine and to 0represent them in characteristic curves.

Specifications:

Comparison of a Pelton turbine as impulse turbine and a Francis turbine as reaction turbine accessories for the Turbine Supply Unit

Operation by use of the Universal Brake and Drive Unit

Constant torques and speeds can be adjusted with Universal Drive and Brake unit

Transparent front panel in the turbines for observing the operating area

Adjustable nozzle needle for setting different nozzle cross-sections (Pelton turbine)

Adjustable guide vanes for setting different angles of incidence (Francis turbine)

A pressure sensor at the Francis turbine for measuring the pressure at the turbine outlet

Digital display for flow rate, pressures, and temperature in Turbine Supply Unit

Braking torque and speed measured in function of a Kaplan turbine

Closed water circuit with a submersible pump, throttle valve, and tank adjustment of flow rate with a throttle valve

Loading the turbine by use of air-cooled eddy current brake impeller with fixed vanes

Adjustable guide vanes for setting different angles of attack

Non-contact speed measurement at the turbine shaft and force sensor at the brake for measuring the torque

Digital display for pressures, temperature, flow rate, speed, and torque

Technical Specifications:

Translation ratio between brake and turbine: 1,44:1 Pelton turbine

Output: 1,5kW at 2750min-1 at 6,5bar

Wheel diameter: 165mm

Variable nozzle setting Francis turbine

Output: 1kW at 3500min-1 and 4,2bar

Wheel diameter: 80mm

Variable guide vane setting Kaplan turbine

Max. output: 1000W

Max. speed: 3700min-1

Control wheel

8 guide vanes, adjustable: -15°...45°

external diameter: 120mm, internal diameter: 60mm

Impeller, 4 vanes, fixed

external diameter: 120mm, internal diameter: 60mm, pitch: 80mm

Submersible pump with motor

Max. flow rate: 250m³/h

Max. pump head: 11m

Nominal power: 3,1kW Tank: approx. 350L Measuring ranges

Temperature: 0...100°C

Pressure (at turbine inlet): 0...1bar rel.

Pressure (at turbine outlet): -1...0,6bar rel.

- Flow rate: 13...200m³/h

Torque: 0...10Nm

- Speed: 0...6500min-1 Stroboscope

Covers the range of 250 - 18000 flashes per minute with an accuracy of ±2%.

Light source is an easily replaceable Xenon Flash Tube.

Optional:

Data Acquisition System

A PC with a Pentium processor

An electronic signal conditioning system

A stand-alone data acquisition modules

A Windows-based software Computer-Aided Learning

Multimedia features

Interactive

Graphic simulation

Experiment results samples

Full experiment manuals

Supervisory Control & Data Acquisition - Data Logging

Signal Analysis

Process Control

Real-Time Display

Tabulated Results

Graph of Experimental Results

Experiment Possibilities

Determination of mechanical output

Determination of efficiency

Recording of characteristic curves

Investigation of the influence of the nozzle cross-section on the power output

Determination of power output curves at different speeds

s Hydraulic power output

s Mechanical power output

Determination of the head

Determination of turbine efficiency

Investigation of the influence of the vane position on power output and efficiency

Services Required:

Mains power supply: 220-240V, 1Ph, 50Hz

91-9829132777

91-9829132777