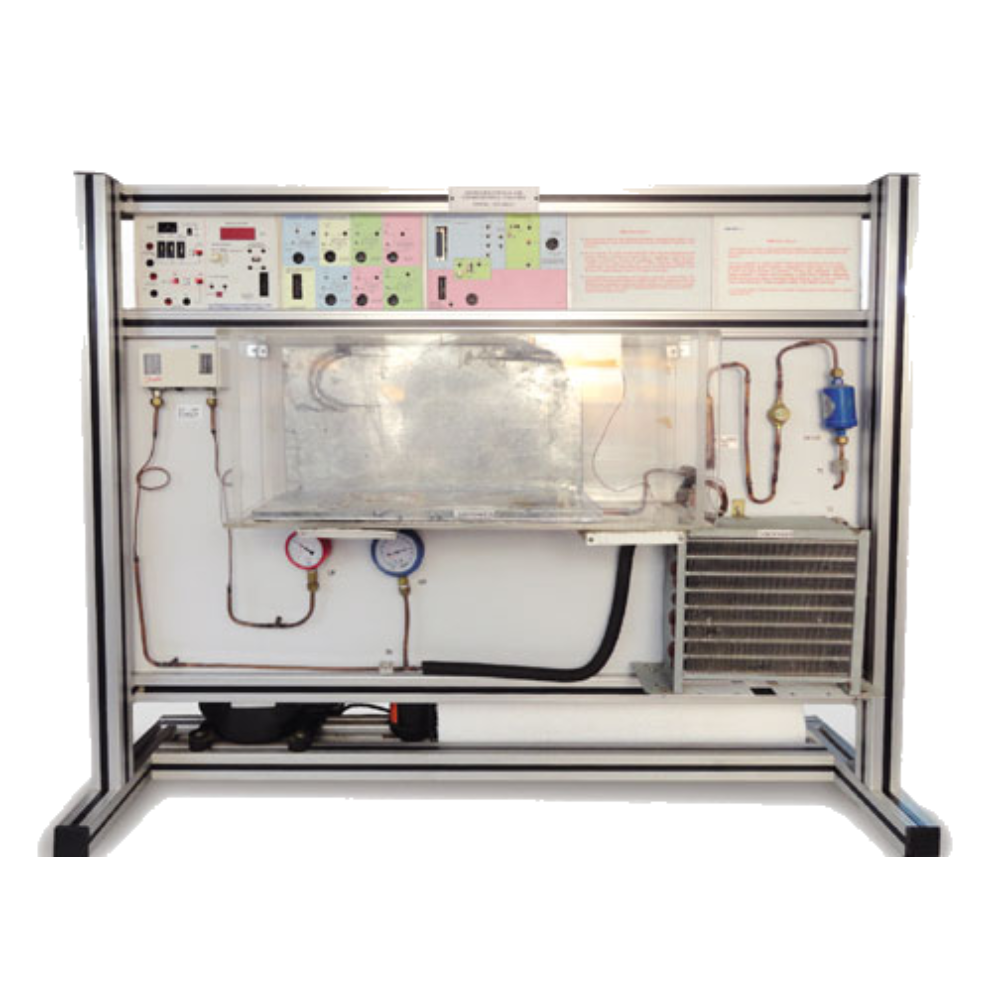

Air Conditioner Trainer

Order Code: 19203430.14

Category: General Lab Equipment III

The Split Air Conditioner Trainer has been designed to explain and demonstrate the working principles of an air-conditioning system. It is mounted in an enamel-coated steel frame angle. All the components that been used are original air-conditioning ...

SPECIFICATION

The Split Air Conditioner Trainer has been designed to explain and demonstrate the working principles of an air-conditioning system. It is mounted in an enamel-coated steel frame angle. All the components that been used are original air-conditioning components by Industrial standard manufacturers. The basic system comprises a compressor, condenser (divided into two sections), expansion device, digital temperature indicator with three PT 100 sensors (measuring condenser, evaporator and cabinet temperature), dryer unit, sight glass, and three pressure / suction gauges. The refrigerant that been used did not contain chlorine which damages the Earth's ozone layer of the Earth, minimal damage to our environments.

- High efficiency compressor (Highly efficient and compact)

- New W-fin condenser (Highly efficient and compact)

- Comp Redesigned (Heat exchanger, various joints, compressor and ETC.) for high pres (Burst rupture pressure 1.6 times).

- Optimum refrigerant cct heat exc Product Specification:- Control Modes Normal mode Fault mode Operating Conditions 0 to 45°C, 85% or Less (R.H.) Input Power AC 240V, 50/60Hz 1-Phase The electrical control box contains an isolator / circuit breaker, voltmeter, ammeter, temperature zone selector switch and

- status indicators for the compressor. Components

- Air Conditioner Unit (Indoor unit)

- Condenser Unit (Outdoor unit)

- Compressor Unit

- Sight Glass

- Filter Drier

- Capillary Tube

- H/L Pressure Switch

- Hot Gas Pressure Gauge Meter

- Liquid Pressure Gauge Meter

- Suction Pressure Gauge Meter

- Voltmeter

- Ammeter

- Temperature Meter Accessorries

- Connection cable

- Experiment manual

- Refrigerant R22

- Gas checking gauges set And all equipment needed has to be supplied to ensure the trainer system is functional Experiment Topics:

- Study of a typical air-conditioning cycle

- Explain and demonstrate airflow and refrigerant flow in the system

- Become familiar with the components used in the system

- Understanding the influence and different control settings on the unit

- Measurement of temperature in the system

- Measurement of pressure in the system

- Control of airflow

- Logical trouble-shooting of various faults

INSTALLING AND COMMISIONING : Installing and commissioning must be done within 1 month from the date of delivery at no additional cost from polytechnic. All installation and commissioning should be completed before training at site can be conducted.

TRAINING AT SITE : Duration: minimum 2 days. No.of participant: minimum 5 persons nominated by the institution. Objective: The trainee must be able to operate

91-9829132777

91-9829132777