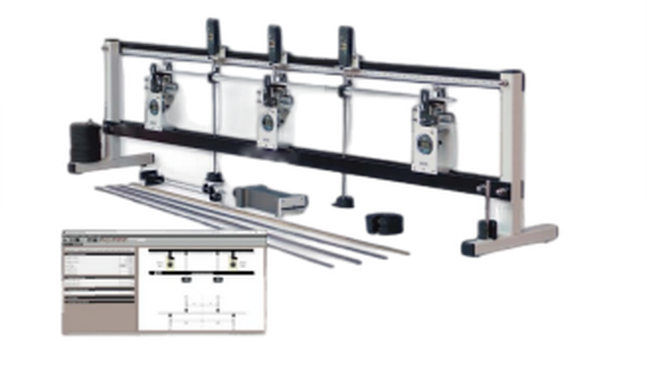

BEAM APPARATUS

Order Code: 22235750.58

Category: General Lab Equipment II

Key Features Ideal for student use and classroom demonstrations Made for maximum fl exibility and ease of use for extensive range of experiments Simply supported and cantilever beam tests with up to four supports with any ...

SPECIFICATION

Key Features

- Ideal for student use and classroom demonstrations

- Made for maximum fl exibility and ease of use for extensive range of experiments

- Simply supported and cantilever beam tests with up to four supports with any loading

- Three load cells with digital indicators measure reaction forces or act as rigid sinking supports

- Precision digital indicators for accurate defl ection measurements

- Weights and hangers supplied to apply point loads

- Supplied with fi ve diff erent test beams

Description

The Beam Apparatus allows an extensive range of experiments to cover virtually all course requirements relating to bending of beams. The basic unit provides facilities for supporting beams on simple, built-in and sinking supports, applying point loads, and measuring support reactions and beam defl ections. It includes five different test beams. A pack of ten additional specimen beams is available for further experiments. The Beam Apparatus can be used for an almost limitless number of experiments ranging from determination of the elastic modulus for beams of diff erent materials, through to studies of continuous beams with any loading. Great care has been taken at the design stage to ensure maximum flexibility and ease of use. The main frame of the apparatus consists of an upper cross-member carrying graduated scales and two lower members bolted to T-legs to form a rigid assembly. The three load cells and cantilever-support pillar slide along the lower members and can be clamped fi rmly in any position. The load cells have direct digital readout and each is fitted with a hardened steel knife edge which can be adjusted to set the initial level or to simulate a sinking support. Locking pins can convert each load cell to a rigid support when required.The cantilever support is a rigid pillar with a sturdy clamping arrangement to hold the beamswhen built-in end conditions are required. Four weight hangers and a set of weights are supplied to apply static loads. Three digital indicators measure all beam defl ections. The indicators mount on magnetic carriers that slide along the upper cross-member. The indicators, carriers, load cells and weight hangers all have cursors that register on the scale (located on the upper cross-member) to ensure easy, accurate positioning. All digital indicators and load cells have sockets and cables for connection to optional Versatile Data Acquisition System. The standard test beams are in three thicknesses and include three diff erent materials. They are suitable for the complete range of experiments covering

different loading and support confi gurations. The optional set of beams provide for experiments on diff erent types of beam including compound, channel and non-uniform

beams of various materials. For quick and reliable tests, optional gives accurate realtime data capture, monitoring and display, calculation and charting of all important readings on a computer (computer not included).

Learning outcomes

- Verification of the bending equation

- Determination of fl exural rigidity and elastic modulus (Young’s modulus)

- Verification of static equilibrium

- Deflection of beams on two simple supports with point loads

- Reciprocal properties for loads and defl ection

- Simple and propped cantilevers with any loading

- Continuous beams, statically indeterminate cases for simply supported beams and cantileverson more than two supports with any loading (including measurement of unknown reactions)

- Simply supported and cantilever beams with sinking supports

With the specimen beams, these additional experiments can be done:

- The eff ects of material and section shape on fl exuralrigidity

- Bending characteristics of a brass/steel compound beam, with and without shearing connection between the two layers

- Equivalent sections, characteristics of a metal-faced wooden beam

- Defl ections on a non-uniform (tapered) beam or cantilever

Standard Features

- Supplied with comprehensive user guide

- Manufactured in accordance with the latest European Union Directives

Recommended Ancillaries

- Additional Specimen Beams

Essential Services

Bench space needed:

2000 mm x 600 mm

Operating Conditions

Operating environment:

Laboratory

Storage temperature range:

–25°C to +55°C (when packed for transport)

Operating temperature range:

+5°C to +40°C

Operating relative humidity range:

80% at temperatures < 31°C decreasing linearly to 50% at 40°C

Sound Levels

Less than 70 dB(A)

Specifications

Is committed to a programme of continuous improvement; hence we reserve the right to alter the design and product specifcation without prior notice.

SM1004:

Nett dimensions and weight:

2000 mm x 580 mm x 550 mm; 43 kg

Packed dimensions and weight:

0.63 m3; 120 kg (approximately)

Deflection indicators:

Digital Indicators with sockets for connection

Load cell supports:

Fitted with digital indicators with sockets for connection

Five test beams supplied:

- 3 steel: 3.2 mm, 4.8 mm and 6.4 mm thick (nominal)

- 1 brass: 6.4 mm thick (nominal)

- 1 aluminium: 6.4 mm thick (nominal)

All beams are of nominal dimensions 19 mm wide x 1350 mm long

SM1004a Specimen Beams:

Nett dimensions and weight:

600 mm x 15 mm x 310 mm; 3.5 kg

Packed dimensions and weight:

0.036 m3; 4 kg (approximately)

Ten test beams supplied:

- 4 steel (1 tapered)

- 1 brass

- 1 steel and brass compound

- 2 aluminium (1 with channel cross-section)

- 1 hardwood

- 1 aluminium and wood compound

All beams are of diff erent dimensions and cross-section

91-9829132777

91-9829132777