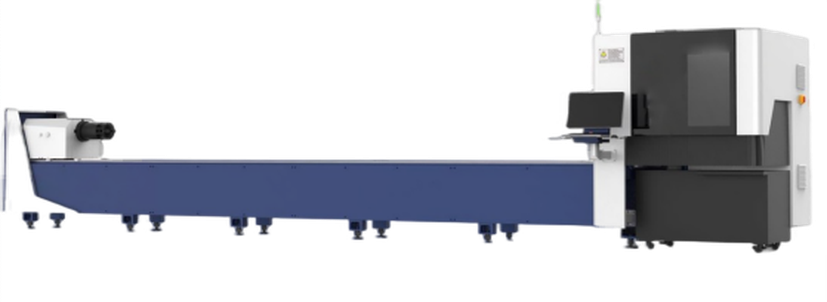

CNC Fiber Laser Pipe Cutting Machine With Laptop

Order Code: 23246338.1

Category: General Lab Equipment II

Features Tube cutting, easy usage, maintenance and service have been achieved by the high-tech of fiber laser Rack & Pinion, Guide Linear and Auto motor should assure high acceleration CNC with laser control function Resonator with refl...

SPECIFICATION

Features

- Tube cutting, easy usage, maintenance and service have been achieved by the high-tech of fiber laser

- Rack & Pinion, Guide Linear and Auto motor should assure high acceleration CNC with laser control function

- Resonator with reflective sensors automatically adapted feed speed and power output for each piece, using CNC

- Highly dynamic equipment Rigidity: high strength transfer due to stability of construction

- Durability: Enclosed drivers

Technical Specifications

- Pipe section shape: Round, Square Tube and Rectangular

- Minimum 1000-Watt tube fiber laser cutting machine

- Working table: 6m with 20 - 155mm dia. or better

- Tube size range: Dia. 20 - 155mm (round & square) and Long side ≤ 155mm (rectangular)

Fiber Laser Source

- Type: Raycus or equivalent

- Direct control of all the fiber laser functions

- Synchronized control of the laser source

- Overall power control and high speed perforation

- Edge machining function and cutting data library

Laser Head

- Type: Raytools or equivalent

- The adjustment of focal length should be accurate to 0.01mm

- IP65 Dust-proof grade

- Control system: FSCUT3000S or suitable

Cooling system

- T-win rack and pinion

- Square Guide Rail: Precise design, easy to install Low noise, smooth movement

- Driving System: Servo Motor with high precise

- Reducer: Helical gear replacing previous spur gear, lower noise

- Back to the gap below 0.05 arc points

- Low pulsating rotation smooth

- Chuck speed: 80 - 100r/min

- Tube load weight: 100 kg or higher

- Working area: 6m tube cutting with 10 - 160 mm diameters

- Y-axis running area: 6.5m

- Z-axis running area: 100mm

- X/Y axis Repeated Position Precision: ±0.02mm

- Power supply: 380 ~ 400V AC, 50Hz, 3 Phase

- Should be included with Nozzle (20 Pcs.), protective lens (10 Pcs.), focus lens (1 Pc.), collimation lens (1 Pc.) and ceramic ring (1 Pc.)

Simulation Software

- The software should combine controller design and implementation into one logical process

- This should reduce learning difficulties and help quickly to understand & create a working control system

- User should be able use the software icons and wire them together on screen, just as they would draw a control system on a piece of paper

- The icons should include important parts of controllers, signal generators, manually controlled signals & voltages and virtual instruments

- The software can be used to record important variables

- Plotting the results in a chart and exporting data for use in other programs

- Students should be able to create one or more types of controller and simulate the theoretical responses

- The user guide should show users how to use the software and how to build and test common control systems

Laptop

- Processor: AMD Ryzen 7 5800H RTX 3050 (16M Cache, 3.2 GHz up to 4.4 GHz)

- RAM: 16GB DDR4

- Storage: 1TB PCIe NVMe TLC M.2 SSD

- Graphics: RTX 3050 4GB GDDR6

- Features: Backlit Keyboard

- Display : 16.1 FHD Antiglare IPS 250 nits 144Hz Narrow Border Flat.

- Operating System: Windows 11 Home

- Battery: 4-cell, 70 Wh Li-ion polymer

- Adapter: 200 W Smart AC power adapter

- WebCam: HP Wide Vision 720p HD camera with integrated dual array digital microphones,

- Wi-Fi: Realtek Wi-Fi CERTIFIED 6 (2×2)

- Ports, Connectors & Slots; 1 Super Speed USB Type-C 5Gbps signaling rate (Display Port 1.4, HP Sleep and Charge); 1 Super Speed USB Type-A 5Gbps Signaling rate (HP Sleep and Charge); 2 Super Speed USB Type-A 5Gbps signaling rate

91-9829132777

91-9829132777