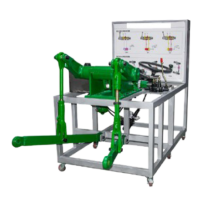

CNC Machine Lathe

Order Code: 23246585.10

Category: General Lab Equipment II

GENERAL REQUIREMENT The bidder shall provide an original letter of appointment from the principal The bidder shall comply to all items without exceptions All tender submitted shall be accompanied by relevant brochure/catalogues describing th...

SPECIFICATION

- GENERAL REQUIREMENT

- The bidder shall provide an original letter of appointment from the principal

- The bidder shall comply to all items without exceptions

- All tender submitted shall be accompanied by relevant brochure/catalogues describing the products

- The brochure/catalogues shall be in original print

- Only system manufactured by reputable firms shall be considered

- System originating from backyard industries or from components assembler shall not be considered

- All system must be fully tested and in running order prior to and after delivery

- Training must be provided on site by competent trainers

- Proof of trainers’ certification must be provided

- Specifications: The machine must have following technical specification

- Fanuc 0iTF controller

- Max swing over bed: 350-370 mm

- Max swing over carriage: 200-220 mm

- Max. cutting length: 490-510 mm

- Rail width: 284 mm

- Spindle nose: A2-6

- Spindle bore: 65mm

- Taper of spindle bore: 1:20

- Chuck size: 6 (optional:8)

- Range spindle speed: 150-4200 rpm

- X-axis travel: 210 mm

- Z-axis travel: 500 mm

- X/Z rapid speed: 20/20 m/min

- Electronic turret: 8

- Max. section of tool: 20x20 mm

- Stroke of tailstock sleeve: 80 mm

- Dia. Of tailstock sleeve: 60 mm/MT4

- Main motor power: 7.5 kW

- Coolant pump power: 370 W

- Overall dimension: 2630x1550x1750 mm

- Include with standard accessories

- 1 unit three phase automatic voltage stabilizer

- 3 pcs of turret block

- 10 box of 9 pcs insert

- 1 set of 9 pcs cutting tools

- Warranty: The warranty period should be 12 months of normal operation and against manufacturer’s defects

- After Sales Service The machine manufacturer must assure at least two (2) years of after sales

- service shall be provided by the tenderer Training

- The successful tenderer shall provide adequate job training to the operator in system operations and routine maintenance of the machine

- The training shall be conducted on-site for 3 days after the installation and commissioning of the machine

- Additional 1 day training as requested within warranty period

- All courses requirement during training should be prepared by the supplier

- Training for at least 10 personnel

- Original training manual in English is provided in hardcopy and softcopy

- The tenderer shall be responsible for the Installation, testing and commissioning and testing the full system to the satisfaction of education centre before any training are to be conducted

- The installation include wiring from power point to machine power inlet

- All the servicing tools and other components essential for the complete and efficient operation of the machine should be supplied at no extra cost

- Maintenance/Support

- Full maintenance and support of the machine must be available

- Details of maintenance scheme shall be outlined by institute and tenderer

- Machine should be back-up with relevant spare parts

- Manual and Documentation

- The successful tenderer shall provide the Page 10 / 25 following manuals

- User manual

- Manual must be in English or Bahasa Melayu

- Technical manual

- Operating manual

- Related inspection/quality/calibration certificate

91-9829132777

91-9829132777