Computer Integrated Manufacturing (CIM)

Order Code: 22235521.2.32

Category: General Lab Equipment I

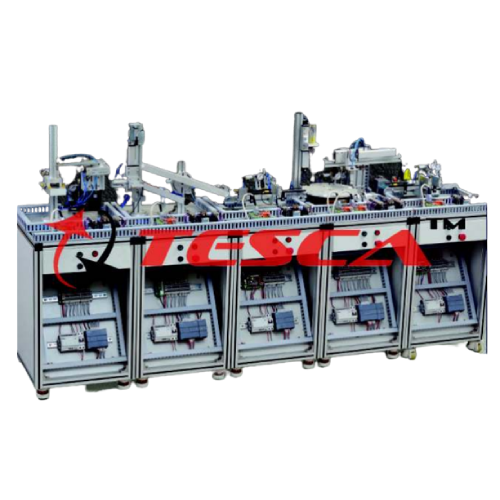

Computer-Integrated Manufacturing (CIM) is a method of manufacturing in which the entire production process is controlled by computer. Typically, it relies on closed-loop control processes, based on real-time input from sensors. Specifications: E...

SPECIFICATION

Computer-Integrated Manufacturing (CIM) is a method of manufacturing in which the entire production process is controlled by computer. Typically, it relies on closed-loop control processes, based on real-time input from sensors.

Specifications:

Each module is implemented with real electronics, mechanics and pneumatics components and has a specific function. As an integrated computer system, the output of one activity serves as the input to the next activity, through the chain of events. The whole system is controlled by one Programmable Logic Controller (PLC) and it can be configured to perform a complete process.

The basic modules are the following:

- Conveyor Unit

- Linear Transfer Unit

- Pick and Place Unit

- Six Station Rotary Table

- Vision Inspection System

- Drilling Module

- Unloading Arm

- Weighing Module

- Palletizer Unit

Any combination of the above modules allows creating different systems. Suggested configurations are shown below:

Software:

- The system includes the software for programming the PLC. PC is not included.

- On request, it can also be supplied with a Supervisory Control And Data Acquisition (SCADA) software and provided with a 7” Human Machine Interface (HMI).

- The software interfaces with the CIM’s PLC.

91-9829132777

91-9829132777