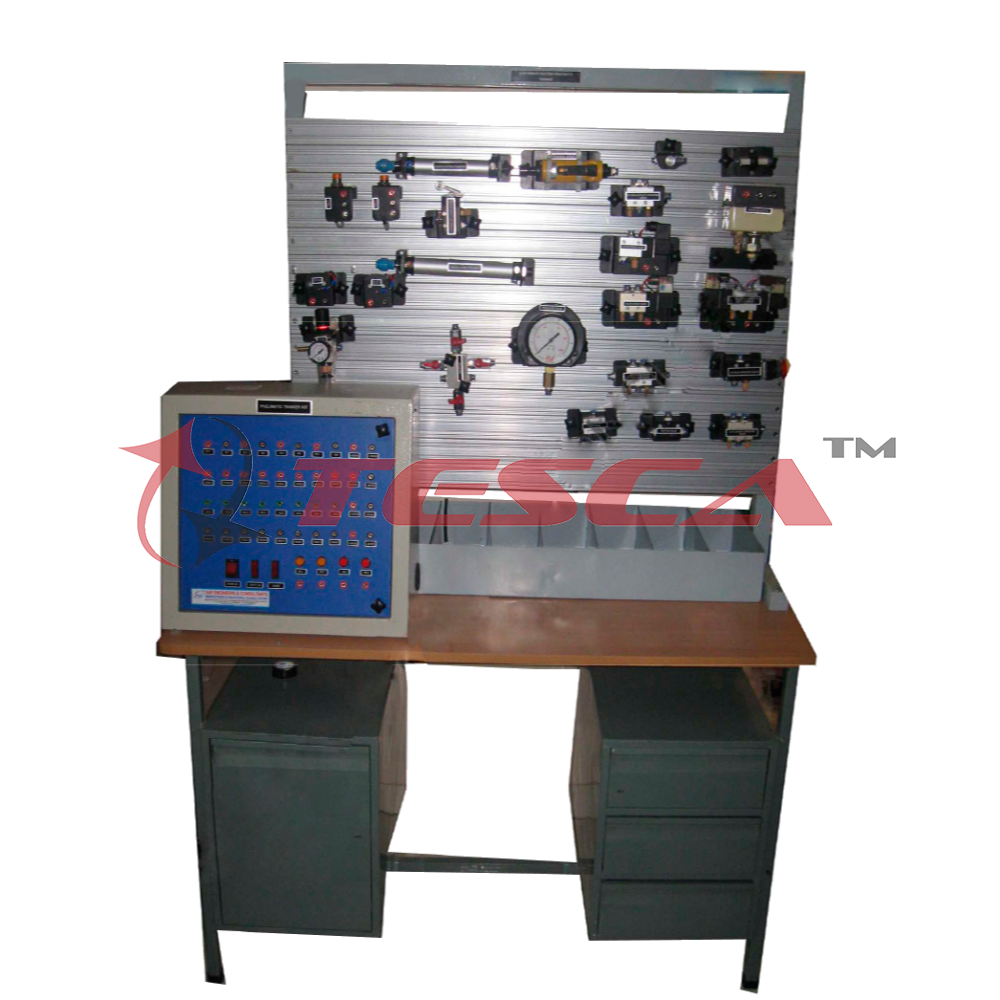

Customized Basic Electro-pneumatic Trainer

Order Code: 52266

Category: Pneumatic Trainers

The basic Customized Electro-Pneumatic Trainer outlines the principal of Pneumatic control used in industrial applications. It explains components of pneumatic control system and their applications. Features Compact Ergonomic Design. User ...

SPECIFICATION

The basic Customized Electro-Pneumatic Trainer outlines the principal of Pneumatic control used in industrial applications. It explains components of pneumatic control system and their applications.

Features

- Compact Ergonomic Design.

- User Friendly, Self Explanatory Systems.

- Leak proof Safety Measures, sturdy piping & Robust Construction.

- Enhanced Electrical Safety Considerations.

- Training Manuals mimic Charts for Operation Ease.

- M.S. powder coated cubical plant with standard Instrument Assemblies.

- Inbuilt Safety Measures to avoid improper usage.

- Relay board logic circuit operation.

Experiments

- Study of pneumatic actuator & reciprocating cylinder trainer kit with different Logical

- Circuits such as OR, AND etc. operations.

- Study of pneumatic cylinders: single acting, double acting.

- Study of construction & operation of pneumatic equipments such as 5/2 Solenoid valve,

- 3/2-way valve, limits switches, pneumatic motor etc.

- Study of pneumatic control systems.

System Specifications

- Double acting cylinder, 3/2 solenoid valve, single acting cylinder with flow restrictors,

- Double Pilot operating 5/2 valve, Single solenoid operating

- 5/2 valve, 5/2 Hand Lever Valve, Pneumatic limit switch (plunger & roller operated),

- Push-button 3/2 valves (monostable), 3/2 Roller Lever Valve, Pneumatic indicators,

- Air supply manifold, Pneumatic motor, AFR Unit, Profile Plate, Flow Control Valve,

- Quick Exhaust Valve, T-Connectors, Shuttle Valve (OR Gate), Dual Pressure Valve

- (AND Gate), Hand Slide Valve, Time Delay Valve, Quick Connectors, Mounting Plates.

Services Required

- Compressed clean, dry air supply at 7-8 Kg/cm².

- 230 VAC single phase motor.

91-9829132777

91-9829132777