Distributed Control System (DCS)

Order Code: 22235427.2.15

Category: General Lab Equipment I

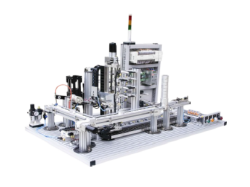

The feedback distributed control system (dcs) trainer is a complete training solution that combines the operations of a leading commercial dcs process management controller package, namely the emerson delta v, with an assortment of our proprietary tr...

SPECIFICATION

The feedback distributed control system (dcs) trainer is a complete training solution that combines the operations of a leading commercial dcs process management controller package, namely the emerson delta v, with an assortment of our proprietary training rigs.

The training rigs offer a range of processes:

- Level & flow

- Temperature

- Pressure

- Forced air cooling

These may be operated separately or combined to produce a multi-process, multi-loop system. The trainer is supplied complete with the pc, software, controller and i/o modules that are needed to monitor and control the process rigs. A control cabinet houses the components that provide the interface between the pc and the rigs. The control cabinet is easily connected to the

Pc and rigs using the supplied cables. The valves, transducers and transmitters associated with the training equipment are standard industrial components that operate using simple 4–20 ma current loop control, and 24 v d.c. The trainer can be used to perform a set of operations that will guide the student from the basics of field components in the process industry to the final control algorithms that are used in various applications.

Curriculum Coverage:

- Distributed control system background theory

- Delta v explorer

- Trainer configuration

- Basic on-off control

- Advanced on-off control

- Levels & alarms

- Sequential function charts

- Pid control

- Shutting down the workstation

Features:

- Windows-based workstation

- Includes a pc with speakers to provide graphical and audible alarms

- Provides a graphical user interface

- Includes an emerson delta v industrial controller

- Continuous & sequential control of processes

- Industry standard 4-20 ma signals with 24 v dc outputs

- 16 analogue & 8 digital inputs

- 8 analogue & 8 digital outputs

- Displays graphical representations of the trainers and processes to simulate an industrial environment

- „design“ & „run“ modes

- Controller & interface package housed in a 19 inch rack

- Software provides an integrated scada environment with i/o tags held in a database

- Comprehensive experiment manual

91-9829132777

91-9829132777