Electrical Machines System Laboratory

Order Code: 23246810.1

Category: General Lab Equipment II

Minimum required didactic content: Isolation transformers and autotransformers Design and connection Equivalent circuit diagrams Transformation ratios No-load and short-circuit experiments Vector groups used in three-phase transformers Motor opera...

SPECIFICATION

Minimum required didactic content: Isolation transformers and autotransformers Design and connection Equivalent circuit diagrams

Transformation ratios No-load and short-circuit experiments Vector groups used in three-phase transformers Motor operation:

Motor connection Comparison of shunt-wound, series-wound and compound-wound machines Typical machine data Open-loop speed control with starter and field regulator Reversing the rotation direction Load characteristics at constant input voltage Measurement evaluations Generator operation:

Generator connection Armature voltage as a function of the exciter current Function and application of the field regulator Voltage control, self-excitation and separate excitation Armature current and armature voltage at constant speed and constant exciter current Load diagram of the generator Star-delta connection, Steinmetz circuit Complied 23246810.1 Reactance power compensation with capacitors of various capacitance Starting, Speed control, Voltage, current and frequency in the rotor Rotor frequency and speed Includes at least the following DIN A4 modules with the following characteristics:

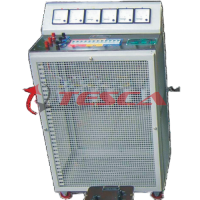

All modules are supplied as a DIN A4 high didactic panel with 4mm secure connection plugs and color printing of wiring diagrams, photos etc. 1x Transformer trainer, 300 VA with motor protection switch Input voltage: 3x 230/400V, 50/60Hz, Output 6x 115V Safety protection via motor protection switches and separate temperature monitoring mechanism Resistive load 3 x 1 kohm, each 100 W, Inductive load 3 x 5 H, 300 mA, Capacitive load 3 x 2µF, 450 V 1x Regulating transformer, exciter 0-200 V (Output voltage : 0...200V, 2A AC/DC 0...30V, 10A AC/DC 1x Set of loads and resistors for 300W machines 1x Exciter power supply for electrical machines, 110W 1x Cut-out switch, tetrapolar 1x Star-Delta switch 1x Capacitive load, three-phase, 14-stage, 3x 1µF / 2µF / 4µF / 8µF 1x Servo motor brake system to perform experiments on the machines Speed or torque control without and with PC / special network synchronization mode 5.7" color touch screen / simultaneous display of mechanical (speed, torque, power) and electrical values (voltage, current, apparent/active/reactive power, cos phi, power factor) Galvanically isolated USB interface / software for measuring mechanical and electrical characteristics Simulation of industrial loads for testing electrical machines (calender, pump, inertia mass, compressor, time-variable load, etc.) with max. torque 10 Nm / speed 4000min-1 Analysis of the motor curve / operating point / characteristics over time with recording of the measured values including load-dependent starting current. Integrated interface for reading electronic nameplates of ESD motor samples Coupling sleeve and guard / Integrated LED protective cover / Motor temperature monitoring. 1x Power supply with adjustable three-phase motor circuit breaker; phases, N, PE on 4 mm safety sockets 1x Didactic RMS voltage/current/power measuring instrument system TRMS Multimeter / Power meter / Power factor meter Separate input for voltage and current / Electrically indestructible up to 20 A/600 V 5.7" color touch screen for the display of 1 to 4 simultaneous digital and analog values Galvanically isolated USB interface with many virtual instruments such as oscilloscope, power meter, voltage/current/power plotter (software included) Includes at least the following electrical machines with the following minimum characteristics: Industrial type machines mounted on chassis with anti-vibration system Coupling with single sleeve without tools on standard table between machine and brake Winding diagram printed on a uniform size panel on the front side of approx. 170 x 140mm Machine terminal board with 4mm safety plugs, always on the front panel on the learner's side. Temperature sensor against thermal overload integrated in each machine ESD electronic chips for automatic transmission of machine data to the brake test bench 1x Multi-function DC machine 2000 rpm, 220V, 0,2kW Functions: Shunt, series and compound-wound motor/generator 1x Universal motor (DC and AC), 3000rpm, 220V, 0,25kW 1x Single-phase induction motor with operating capacitor and auxiliary capacitor, 2870 rpm, 0,37 kW 1x Three-phase-asynchronous motor, 1380 rpm, 690/400V, 0,37kW 1x Three-phase multi-function machine, 1420/1500 rpm, 400/230 V, 0,27 kW Three-phase asynchronous motor with slip rings, Synchronous machine All accessories necessary for proper operation must be provided, with at least the following: 1x Regulated high voltage power supply for the supply of DC machines, 1000W, 500V 1x Mobile aluminium experiment stand, 3 levels, 6 x earthed sockets 30-mm table top made of highly compressed, multi-layer chipboard, Resistant to heat and many chemicals Frame with solid impact-resistant protective edging made of 3mm thick RAL 7047 coloured plastic Coating and adhesive are PVC free Power strip with 6 outlet sockets mounted underneath the table top, lead and earthed plug 2 extruded aluminium profiles with multiple grooves 1800 x 120 x 40 mm (WxHxD) 8 equally sized grooves in extruded aluminium profiles (3 on each side and 1 each on the front and back) Table frame made of tough combination of rectangular tubing around the full perimeter PC and Monitor holder 1x Interactive multimedia courses Interactive experiment setups with animation Measured values and diagrams can be stored in the experiment instructions per drag and drop Direct link to instruments/measurement and test software from the experiment instructions Includes questions with feedback and evaluation logic for progress monitoring Documents can be printed out for hardcopy of experiment instructions including solutions 1x Power supply for tables (2x CEE 16A, 230V, circuit breaker) 1x 4mm safety measuring cable set and 19/4mm safety plug set 1x digital multimeter 1x Standard branded PC with 24'' screen, adapted keyboard, Windows 10 or 11, UPS, spare battery Technical Clauses:

? The bidder must present a manufacturers authorization

? Training manual for the items in form of an interactive software course

? Software packages needed for conducting experiment using these items

? The supplier must provide Minimumu 3 days of training to max. 15 trainers

91-9829132777

91-9829132777