ELECTROHYDRAULICSYSTEM

Order Code: 25268435.2

Category: General Lab Equipment V

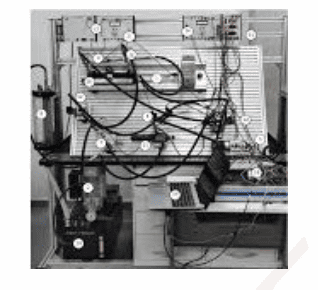

System Overview The Electro-Hydraulic Training Set offers an advanced learning platform for students and professionals in hydraulic system design and automation. With an integrated combination of electro-hydraulic components, this training system ...

SPECIFICATION

System Overview

The Electro-Hydraulic Training Set offers an advanced learning platform for students and professionals in hydraulic system design and automation. With an integrated combination of electro-hydraulic components, this training system allows learners to gain in-depth knowledge of hydraulic circuits, electro-hydraulic control, and their practical applications in industrial environments. This system is ideal for mastering the operation and construction of basic hydraulic circuits, reading electrical and hydraulic diagrams, and troubleshooting hydraulic systems.

Key Components & Specifications

Training Panel

-

Material: Anodized aluminium

-

Size: 1200 × 750 × 30 mm

-

Groove Spacing: 25 mm

Hydraulic Power Pack

-

Hydraulic Capacity: 5 liters

-

Operating Pressure: 60 bar

-

Motor: Single-phase, 50 Hz

-

Voltage: 230 VAC

-

Hydraulic Oil (HLP22): 5 liters

Electrical Components

-

Relay Module (3-fold): 24 VDC, 4C (changeover), Max 5A contact load, 20ms operating/block time

-

Push Button Set: 24 VDC, 1 momentary, 1 locking, 2 open/2 closed contacts, Max 1A load

-

Limit Switches: Left & Right actuation, 24 VDC, 5A, 1C contact, 200 Hz max frequency

-

Inductive Sensor: DC10–30V, 5mm switching distance, PNP NO, 500Hz switching, 200mA max output

-

Power Supply Unit: Input 230VAC, Output 24VDC / 4.5A, short-circuit protection

Hydraulic Components

-

Hydraulic Distributor: Pressure range 0–120 bar, 6 couplings for distribution, operating pressure 60 bar

-

Pressure Gauges (x2): 0–100 bar range, 1.6% precision, glycerin buffer, 60mm diameter

-

Flow Control Valve: 0–120 bar, 10L/min flow rate, 60 bar operating pressure

-

Check Valve (1 bar): Pressure range 0–120 bar, operating pressure 60 bar, 1 bar check pressure

-

Pressure Relief Valve (directly controlled): Pressure range 0–120 bar, 60 bar operating pressure

-

2-Way & 3-Way Flow Control Valves: Manual override, pressure compensative flow control, pressure range 0–120 bar, operating pressure 60 bar

-

Double Acting Cylinder: Ø16mm piston, Ø10mm piston rod, 200mm stroke, pressure range 0–120 bar

-

Pilot Actuated Check Valve: Pressure range 0–120 bar, operating pressure 60 bar

-

T-Connectors (x3): For 4mm hoses, 0–120 bar pressure range, operating pressure 60 bar

Control Valves & Components -

4/2-Way Solenoid Valve: Pressure range 0–120 bar, 60 bar operating pressure, power consumption 27W, 24VDC with LED & protection circuit

-

4/3-Way Double Solenoid Valve (PABT blocked): Pressure range 0–120 bar, 60 bar operating pressure, 27W power consumption

-

Electrical Limit Switches (Left & Right Actuation): 24VDC, 5A, 1C contact, 200 Hz switching frequency

-

Pressure Remover: For relieving residual pressure

-

Hydraulic Hoses (600mm & 1000mm): Pressure range 0–120 bar, operating pressure 60 bar, temperature range -40°C to 125°C, min flexibility 80mm

Additional Features & Accessories

-

Manual Override Options for Flow Control and Pressure Compensative Valves

-

Electrical Cable Set: Includes red and blue cables of various lengths for flexible connections

-

Power Supply Unit: AC230V, Output 24VDC / 4.5A, with short circuit protection

-

Hydraulic Hoses: 8 sets each for 600mm and 1000mm length, pressure rated for 60 bar

-

Pressure Gauge, Flow Control Valves, and More for customized setups and experimentation

Documentation

-

Textbook – Electro-Hydraulics (English)

-

Workbook – Basic Electro-Hydraulics (English)

Applications

-

Hydraulic and Electro-Hydraulic System Design: Learn how to design and operate basic hydraulic circuits, control valves, and cylinders.

-

Electro-Hydraulic Control Systems: Build and troubleshoot electro-hydraulic systems with real-time control and monitoring.

-

Industrial Training: Ideal for training in industries such as automotive, aerospace, and manufacturing, where hydraulic systems are critical.

-

Hands-on Education: Perfect for students and professionals in engineering fields to gain practical skills in hydraulic automation and control systems.

This Electro-Hydraulic Training System offers an ideal learning environment for mastering hydraulic technology and its integration with electrical control systems. Whether for technical colleges or industrial training programs, it provides students with the practical skills needed to design, construct, and operate hydraulic circuits in real-world applications.

91-9829132777

91-9829132777