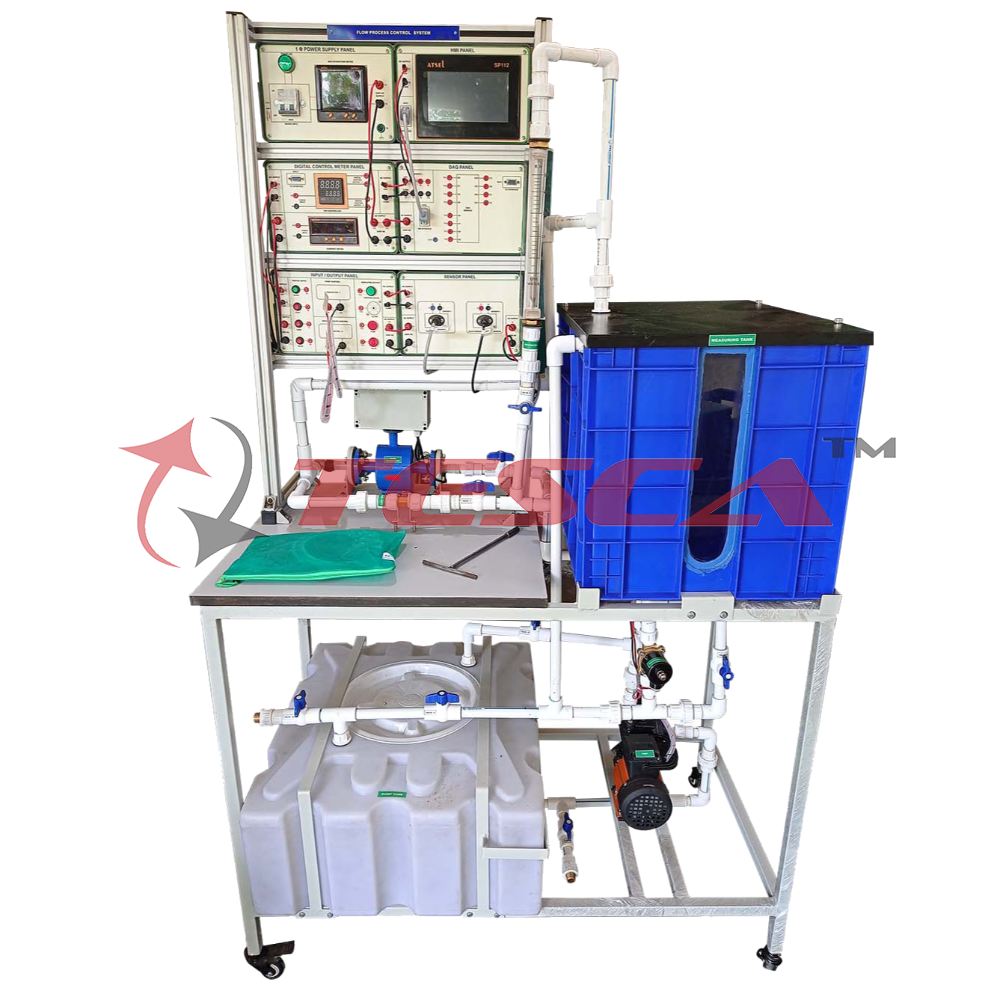

Flow Process Control Trainer

Order Code: 52009B.1

Category: Process Control Trainers

52009B.1 Flow Process Control Trainer consists of an instrument panel and a different type of flow sensor area that is useful for study of the principal and working of specialized dedicated flow measuring setup. This system comprises of the late...

SPECIFICATION

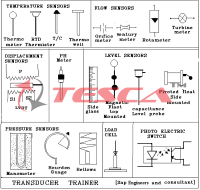

52009B.1 Flow Process Control Trainer consists of an instrument panel and a different type of flow sensor area that is useful for study of the principal and working of specialized dedicated flow measuring setup. This system comprises of the latest components, which reflect the newest technological innovations in this field. Flow Process Control Trainer assists students and industry professionals in understanding the concepts and workings of flow measuring instruments. This further enables them to learn advance and more complex flow process; and contribute to the growth of the instrumentation area. Flow Process Control Trainer includes different types of Flow Sensors including, Turbine Flow Sensor, Wheel Flow transmitter, Rotameter, Sump Tank & Acrylic measuring tank. It encompasses safety measures such as emergency shutdown and over heating protector. 52009B.1 allows the user to perform a wide range of experiments while learning intricate concepts in an interactive and simple manner.

Features

- Different Types of Flow Sensors like, Rotameter,

- Turbine Flow Sensor, wheel flow transmitter .

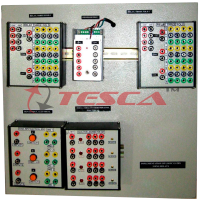

- Start, Stop, Pump, Solenoid Valve, Visual Indicator, Audio Indicator, Pump, and Solenoid Valve

- Real time DAQ Interface with ADC and Digital input/output

- Industrial process control design

- Heavy duty bench Workstation

- Electrical Control Panel

- Interface with Ethernet based DAQ

- 8 Channel 24 bit ADC DAQ

- Data Logging

- Acrylic Measuring tank with Scale & Sump Tank

- User friendly, self explanatory system

- Enhanced electrical safety consideration

- Powder coated frames with standard instrument mounting

- Caster Wheel (with locking mechanism) provided at the legs of the Workstation for easy movement

- MCB with AC supply for safety purposes

Experiments

- Characteristics of Turbine Flow Sensor

- Characteristics of Rotameter

- Characteristics of Wheel Flow Transmitter

Technical Specification

- DAQ : 1no.(Data Acquisition System)

- Analog Inputs : 4 nos.

- Digital Inputs : 4 nos.

- Digital Outputs : 4 nos.

- ADC Resolution : 24 Bit

- Two Unity Gain Amplifier : 0 to 5V

- Ethernet : Yes

- Data Logging : Yes (PC based)

- Rs485 Interface : Yes (PC based)

- Rotameter : 1no.

- Range : 0 to 2500 LPH

- Material : Acrylic

- Mounting : Horizontal

- Wheel Flow Transmitter : 1 no.

- Supply : 24V DC

- Output : 4 to 20mA

- Flow : 0 to 30LPM

- Turbine Flow Sensor : 1no.

- Supply : 5V DC

- Output : 0 to 5V

- Flow : 0 to 30 LPM

- Pump : 1no.

- Power : 0.5 HP

- Supply : 230V

- Solenoid Valve : 1no.

- Supply : 230VDC

- Indicator : 4 nos.

- Push to on Switch : 6 nos.

- Toggle Switch : 3 nos

- Digital Panel Meter : 2 nos.

- Supply : 230V.

- Display : 4 Digit display

- Input : 4-20mA Current

- AC Voltmeter : 1 no.

- Voltage : 10 - 450Vrms

- Accuracy : ± (1% reading 2 digits)

- AC Ammeter : 1 no.

- Current : 0.2 - 10Arms

- Manual Valve : 8 nos.

- Measuring Tank : 60 Liter

- Sump Tank : 100 Liter

- Caster Wheels : 8 (4 with lock & 4 without lock)

- Size : 75mm

- Dimension in mm : H1640 x W 1320 x D 765 ( 2474)

- H1135 x W 1408 x D 715 (for Sensor Unit)

- Included Accessories : 4mm Patch Cord 18”-15 nos.,

- Ethernet Cable-1 no.

- Windows OS Based PC (optional)

- Note: Windows OS Based Computer is required to explore DAQ experiments

91-9829132777

91-9829132777