Foaming Characteristics of Lubricating Oil Foaming Tendencies of Engine Coolant - (ASTM D1881)

Order Code: MT826

Category: Petroleum/Grease/WAX Testing Equipment's

Compliance with following International Standards ASTM D1881 Purpose This test method covers a simple glassware test for evaluating the tendency of engine coolants to foam under laboratory controlled conditions of aeration and temperature. Ap...

SPECIFICATION

Compliance with following International Standards

ASTM D1881

Purpose

This test method covers a simple glassware test for evaluating the tendency of engine coolants to foam under laboratory controlled conditions of aeration and temperature.

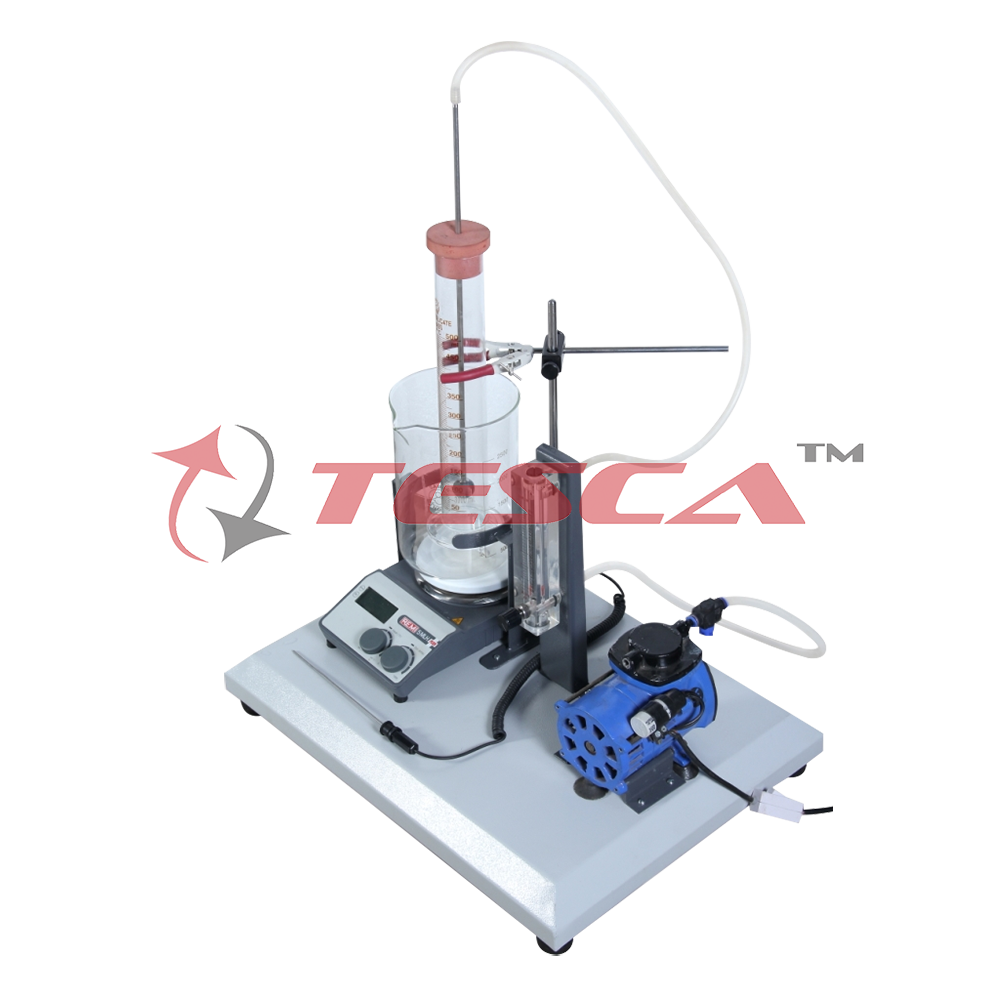

Apparatus Description

The complete set?up will be supplied with following parts and accessories.

1. Test cylinder

- Capacity : 500?mL graduated container of heat resistant glass

- Material : Made of Borosilicate glass material

- Diameter : 45 to 50 mm

- Height : 380 mm

2. Magnetic Stirrer with Hot Plate (Heat Source)

- Magnetic stirrer with hot plate will serve the purpose of heating temperature requirements.

- Stirring capacity : 5 Liters

- Speeds range : 100 ? 1500 rpm

- Material of hot plate : Porcelain Enamel Hot Plate model

- Temp range : Up to 340 °C

- Temp accuracy : ± 1 °C

- Temp Sensor : External temperature probe (PT?1000) for control of fluid temperature

- Display : Easy?to?read backlit LCD for display of set & actual parameters

- Monitoring of set & actual temperature / speed

- High accuracy of temperature control with embedded dual sensors

- Last parameter recall, ideal for repetitive processes

- Scratch proof & excellent chemical resistance top plate

- A mode for running without external temperature sensor

- B Mode for control of temperature through external sensor

- Advanced Stirrers with microprocessor technology ,

- Unique safety temperature control system

- Constant speed even with change of load / Voltage,

- Settable safe temperature limit to avoid overheating

- Residual Temperature warning when unit is switched off for operator safety

3. Spherical Diffuser stone

- Spherical diffuser stone with defined pore diameter as per ASTM D?1881 Standard.

- Connection for rubber tubing : A cadmium?plated brass nipple fitting serrated for 0.5cm (3/16") rubber tubing

- Material of diffuser stone : Made of Alundum fused crystalline aluminum oxide.

- Permeability @ 2.45 kPa : 3000 to 6400 mL of air/min

- Pore diameter : not greater than 80 Micro meter

- Diffuser stone diameter : 1 inch (25.4 mm)

- Connection for rubber tubing : A cadmium?plated brass nipple fitting serrated for 0.5cm (3/16") rubber tubing

4. Supply tubing

- Aerator tube having diameter of 1 inch (25.4 mm)for gas diffuser stone. This tube is connected to the spherical diffuser stone to supply the air pressure from pump.

5) Flow meter

- Rotameter assembly with flow control valve capable of maintaining the flow of 1000 ± 25 mL/min through spherical diffuser stone.

6. Digital stop watch

- Digital stop watch for observing and calculating time for gas supply through flow meter and for foam breakdown.

7. Air source (Air compressor)

- A clean and dry source, free from grease and other contaminants, capable of maintaining the prescribed flow rate as per ASTM D1881 requirement through the diffuser stone.

8. Rigid base support

- Entire setup is mounted on metal rigid frame which is powder coated in attractive shades.

9. Thermometer

- ASTM Partial Immersion Thermometer number ? 1C having a range from −20 to +150°C (0 to 302°F)

91-9829132777

91-9829132777