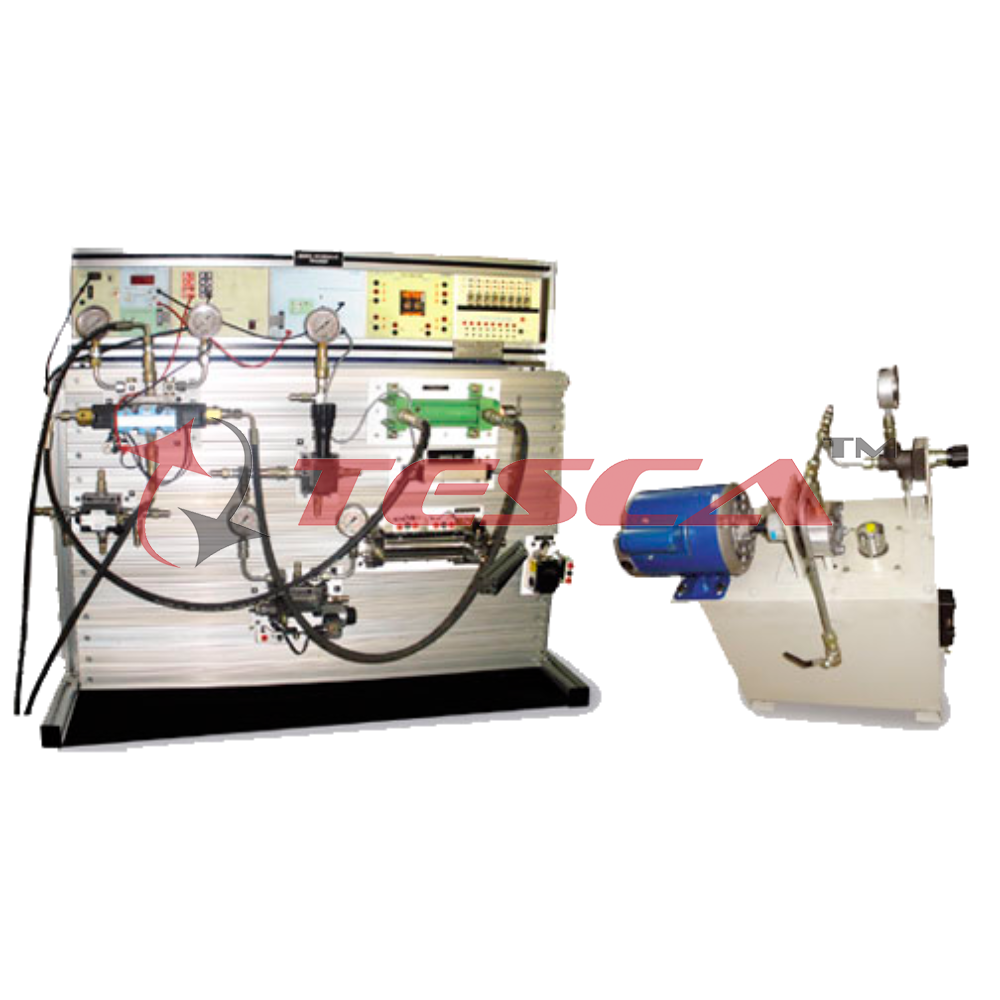

Hydraulics Bench

Order Code: 22236099.52

Category: General Lab Equipment I

Features: Choice of 2 top models Hydraulic/Electro Hydraulic trainer (Optionally PLC may be supplied.) / Use of aluminium profile grooved plate (CD=25mm) experiment board. Optionally table with drawers (3 nos.) To store components when not in u...

SPECIFICATION

Features:

- Choice of 2 top models Hydraulic/Electro Hydraulic trainer (Optionally PLC may be supplied.) / Use of aluminium profile grooved plate (CD=25mm) experiment board. Optionally table with drawers (3 nos.) To store components when not in use & 4 Nos. of caster wheels.

- Qui9ck release socket plug arrangement for building circuits, Lighter pneumatic components are mounted using lever operated mounted adapters for quick release & placement.

- List of components may be modified as per your requirement.

- Top electrical panel row exists in electro hydraulic / Pneumatic only.

- Power Generation

- Power pack (50 bar) consist of :

- Tank 25Ltr.

- Gear pump 3LPM with ball valve for flow measurement in Beacker (optional),

- Electric motor 0.5 HP 1440 RPM 230vac,

- Oil Breather Oil level indicator, sunction filter / Strainer Return line filter, 70 bar Gage ,

- Relief valve.

Mechanicla Dimension

- Anodised sturdy Aluminum profile rack (table top) with groove experiment board (Optibally double sided).

- Totel dimension : 1165mm (W) X 800mm (H), Aluminum grooved T bolt Board : L = 107 cm, W = 70cm. Height 700mm Reclining at 00, 200,300, . Oil Tray (107 cm A 300 cm X 2cm) power coated MS

- NET Weight : 70/75 kg. (Electrohyd), Gross Weight : 85/90kg. (Electrohyd).

Optional Experiments only for Electrohydraulic Trainer

- Servo position control (Close loop) consisting of CIP panel with servo control using relay control circuit, power supply for stroke length display, liner motion (100mm, stroke) potentiometer (5KW) as a position sensor coupled to D. A. cylinder.

- Proportional flow and direction control valve with built in amplifier with ±5V l/P voltage to control flow and direction 5KW servo pot to sense Position coupled to D.A. cyliner, open loop position contron, Emt8 panel to display stroke length.

- Proportional flow and direction control valve with amplifier card & LVDT feedback close

91-9829132777

91-9829132777