Industry Smart Manufacturing

Order Code: 23246398.10

Category: General Lab Equipment I

This laboratory must reproduce a collaborative environment to study concepts related to Industry 4.0, integrating small-scale subsystems that are normally found in a manufacturing plant. As a matter of fact digitalization of information, combined ...

SPECIFICATION

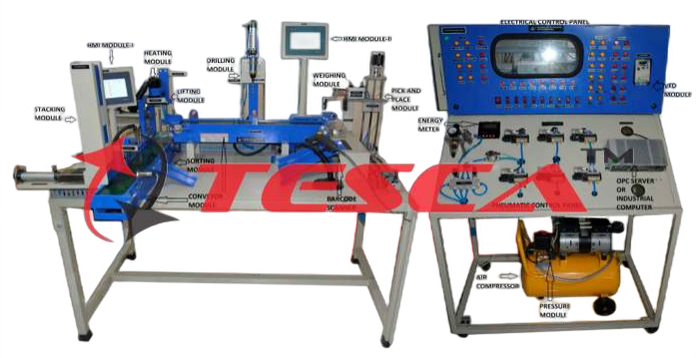

- This laboratory must reproduce a collaborative environment to study concepts related to Industry 4.0, integrating small-scale subsystems that are normally found in a manufacturing plant. As a matter of fact digitalization of information, combined with high-performance hardware, allows the implementation of more flexible and optimized production architectures.

- The trainer must be composed of a set of electronic boards to study the different subsystems that can be found in a real production line. Using an open-source oncrocontroUer connected to a SCADA software for data acquisition and control, the students shall be able to perform practices covering topics that range from the introduction to automation and robotics, communication protocols (TOT), sensors and actuators to a complete study of a prodUctive system related to industry 4.0.

- This laboratory must include the main characteristics described below.

- Approach With this trainer, the student shall get familiar with the different parts that make up a real industrial process and shall learn the corresponding concepts gradually, starting from the study of basic hardware until the practical realization of a scale production line.

- Multidisciplinary laboratory organized by levels ranging from the most basic concepts of electronics and automation to the simulation of an industrial process applying industry 4.0 concepts into practice.

- Hands-on training platform based on experiments.

- Modularity: It must be possible to study independently each subsystem or linked together for the simulation of a complete production line. Scale model of the systems that make up a 4.0 factory including RF1D (Radio-Frequency Identification), Robotic Arm, Conveyor belt and a semi-automatic warehouse. Reconfigurable modular laboratory. Platform for project development. Open SCADA web: The entire system shall be controlled by an industrial SCADA (Supervision and Control Data Acquisition) software that must communicate with all the trainer subsystems and show the data from the sensors, the status and the system control, in real time. Learning platform based on structured software with a didactic approach (CAI). Open and customizable software.

- Supervision and control interface remotely accessible, Skills development: Through an open source platform, students will be able to develop applications using programming and control techniques.

- The trainer shall be a platform to simulate real scenarios. Development of analytical and problem-solving skills. This multidisciplinary laboratory shall aim to provide a practical and progressive learning tool to be used throughout a course in basic electronics, automation and process control, thus developing skills at various levels. Technical and vocational schools: Circuit theory.

- Programming fundamentals. Sensors y actuators. Robotics, telecommunications and electronics engineering courses: Study of commimicniion- protocols, RFID, Bluetooth, IOT.

- Automation and control theory. Microcontrollers. Engineering colleges and universities: Theory and process optimisation. Information theory. Industrial automation The laboratory must include the modules described.

91-9829132777

91-9829132777