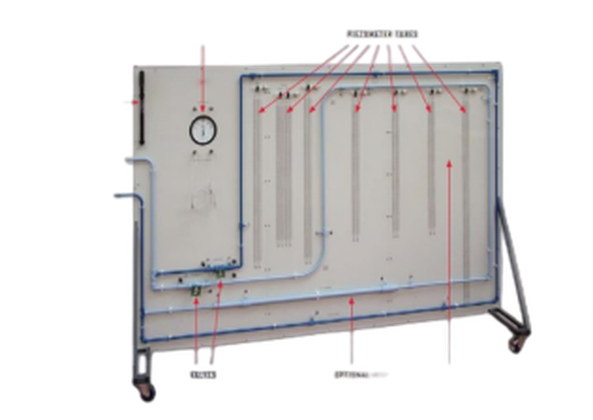

LOSSES IN PIPING SYSTEMS

Order Code: 22235750.28

Category: General Lab Equipment II

Key Features: Mobile, space-saving panel that includes the common pipework parts used in domestic heating systems Includes two colour-coded water circuits Works with Digital Hydraulic Bench for easy installation Includes diff erent p...

SPECIFICATION

Key Features:

- Mobile, space-saving panel that includes the common pipework parts used in domestic heating systems

- Includes two colour-coded water circuits

- Works with Digital Hydraulic Bench for easy installation

- Includes diff erent pipe bends and valves to compare losses

- Fitted with a range of piezometers and a pressure gauge to give accurate pressure measurement

- Optional ‘roughened pipe’ ancillary to investigate flow characteristics in a roughened pipe

Learning Outcomes:

A comprehensive range of investigations into losses in a variety of pipes and pipe system components.

Including:

- Straight pipe loss

- Sudden expansion

- Sudden contraction

- Bends with diff erent radii

- Valves

- Elbows

- Flow in a roughened pipe – needs the optional Roughened Pipe

Key Specifications

- Two circuits

- Sudden expansion and contraction

- Gate valve and globe valve

- Elbow

- Mitre bend

- Three smooth 90-degree bends

Description

The Losses in Piping Systems apparatus is a vertical panel with two separate hydraulic circuits, colour-coded for clarity. Each circuit includes various pipe system components. The unit has wheels for mobility, which also help when storing the apparatus. The Digital Hydraulic Bench (available separately) supplies each circuit with a controlled flow of water. This allows students to study fl ow through the various pipe forms and components, and study and compare the pipe and component characteristics.

The circuits are made of small-bore copper pipe, used in a wide variety of applications such as domestic centralheating systems. The small bore allows the circuits to include many pipe bends and components, while preserving eff ective upstream and downstream test lengths. To measure pressure loss across components, the panel includes

piezometer tubes and a pressure gauge. The pressure gauge measures pressure loss across valves; the piezometer tubes measure pressure loss across the other components. Included is a hand-pump to adjust the datum position of the piezometers. Both circuits have common inlet and outlet pipes, controlled by valves.

The valves are at the outlet to minimise fl ow disruption.The optional ‘roughened pipe’. This can fit to the Losses in Piping Systems apparatus or be used by itself (fi tted to a wall and connected to a hydraulic bench). It includes a pipe with a roughened internal bore, and pressure tapping points connected to a manometer. The manometer measures the pressure drop due to the pipe. Students compare their experimental results with Moody and Nickuradse charts.

Standard Features:

- Supplied with a comprehensive user guide

- Five-year warranty

- Manufactured in accordance with the latest European Union directives

- ISO9001 certified manufacturer

Essential Base Unit

• Digital Hydraulic Bench

This product will also work with existing Gravimetric and Volumetric Hydraulic Benches

Typical Work Assignments

Globe and Gate Valve Loss Coefficients

This experiment takes results of the pressure losses across the two valves at diff erent fl ow

rates and converts them to loss coeffi cient (K) values for comparison. The chart compares

them by plotting the results against percentage fl ow rate.

Elbow and Mitre Head Loss

This experiment compares the losses across the elbow and mitre bends at diff erent fl ow rate and converts them to bend loss (hB) by excluding other losses.

The chart compares them by plotting the results against V2/2g which produces fairly linearresults.

Detailed Specification –

Is committed to a programme of continuous improvement; hence we reserve the right to alter the design and product specifi cation without prior notice.

Nett dimensions and weight:

2600 mm x 800 mm x 1700 mm, and 95 kg

Approximate packed dimensions and weight:

4.3 m3 and 150 kg

Parts:

- Small-bore straight pipe (nominally 13.6 mm bore copper)

- Larger-bore straight pipe (nominally 26.2 mm bore copper)

- Sudden expansion (13.6 mm to 26.2 mm)

- Sudden contraction (26.2 mm to 13.6 mm)

- 90-degree mitre bend (no radius)

- Elbow (13.6 mm radius)

- Small radius, smooth 90° bend (50 mm radius)

- Medium radius, smooth 90° bend (100 mm radius)

- Large radius, smooth 90° bend (150 mm radius)

- Gate valve and Globe valve

Detailed Specification:

Is committed to a programme of continuous improvement; hence we reserve the right to alter the design and product specifi cation without prior notice.

Nett dimensions and weight:

1200 mm x 200 mm x 200 mm, and 3 kg

Approximate packed dimensions and weight:

0.05 m3 and 5 kg

Internal coating thickness:

300 m to 600 m

Pipe diameter:

19 mm

Space needed

Fitted to the 1.5 m x 0.3 m of wall

Operating Conditions

Operating environment:

Laboratory

Storage temperature range:

–25°C to +55°C (when packed for transport)

Operating temperature range:

+5°C to +40°C

Operating relative humidity range:

80% at temperatures < 31°C decreasing linearly to 50% at 40°C

91-9829132777

91-9829132777