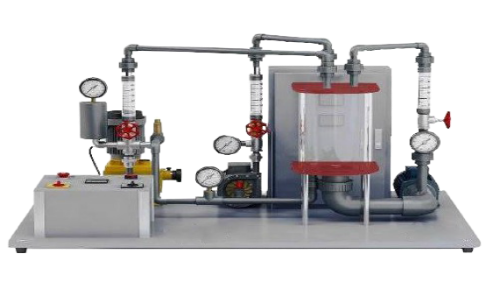

Multi Pump Trainer Unit

Order Code: 21224924.2.3

Category: General Lab Equipment II

Scope: The trainer kit should come as a single compact unit Computer Controlled Multi pump Testing Bench Unit with Real -time SCADA system: Unit designed to demonstrate the operating characteristics of several types of pumps. Anodized alu...

SPECIFICATION

Scope:

The trainer kit should come as a single compact unit

Computer Controlled Multi pump Testing Bench Unit with Real -time SCADA system:

- Unit designed to demonstrate the operating characteristics of several types of pumps.

- Anodized aluminum frame and panels made of painted steel.

- The unit includes wheels to facilitate its mobility.

- Main metallic elements made of stainless steel.

- Diagram in the front panel with distribution of the elements similar to the real one.

- Fully instrumented self-contained unit.

- The unit is mounted on a structure with a work surface covered by a plastic sheet.

Following types of pumps should be embedded in the compact unit

Rotodynamic Pumps

- Centrifugal Pump I

- Centrifugal Pump II in series and parallel

- Axial Flow Pump

- Turbine Pump or Peripheral Pump Positive Displacement Pump

- Gear Pump

- Flexible Impeller Pump

- Diaphragm pump

- Plunger Pump (Piston Pump)

1.Centrifugal Pump (1& II)

- Determination of the curve Q vs r.p.m. of the centrifugal pump.

- Determination of the curve H vs Q for different r.p.m. of the centrifugal pump.

- Determination of the mechanical power vs flow for different r.p.m. of the centrifugal pump.

- Determination of the curve η vs the flow for different r.p.m. of the centrifugal pump

- Determination of the map of a centrifugal pump.

- Coupling in series of two centrifugal pumps of different characteristics.

- Coupling in series of two centrifugal pumps with the same characteristics.

- Parallel coupling of two centrifugal pumps with similar characteristics & Parallel coupling of two centrifugal pumps of different characteristics

2. Axial Flow Pump

- Determination of the curve Q vs r.p.m. of the axial pump.

- Determination of the curve H vs Q for different r.p.m. of the axial pump.

- Determination of the mechanical power vs flow for different r.p.m. of the axial pump.

- Determination of the curve η vs the flow for different r.p.m. of the axial pump.

- Determination of the map of an axial pump.

3. Turbine Pump or Peripheral Pump

- Determination of the curve Q vs r.p.m. of the peripherical pump.

- Determination of the curve H vs Q for different r.p.m. of the peripherical pump.

- Determination of the mechanical power vs flow for different r.p.m. of the peripherical pump.

- Determination of the curve η vs the flow for different r.p.m. of the peripherical pump.

- Determination of the map of a peripherical pump.

4. Gear Pump

- Determination of the curve Q vs r.p.m. of the gear pump.

- Determination of the curve H vs Q for different r.p.m. of the gear pump.

- Determination of the mechanical power vs flow for different r.p.m. of the gear pump.

- Determination of the curve η vs the flow for different r.p.m. of the gear pump.

- Determination of the map of a gear pump.

5. Flexible Impeller Pump

- Determination of the curve Q vs r.p.m. of the flexible impeller pump.

- Determination of the curve H vs Q for different r.p.m. of the flexible impeller pump.

- Determination of the mechanical power vs flow for different r.p.m. of the flexible impeller pump.

- Determination of the curve η vs the flow for different r.p.m. of the flexible impeller pump.

- Determination of the map of a flexible impeller pump.

Diaphragm Pump

- Determination of the curve Q vs r.p.m. of the diaphragm pump. Determination of the curve H vs Q for different r.p.m. of the diaphragm pump.

- Determination of the mechanical power vs flow for different r.p.m. of the diaphragm pump.

- Determination of the curve η vs the flow for different r.p.m. of the diaphragm pump.

- Determination of the map of a diaphragm pump.

Plunger Pump

- Determination of the curve Q vs r.p.m. of the plunger pump.

- Determination of the curve H vs Q for different r.p.m. of the plunger pump.

- Determination of the mechanical power vs flow for different r.p.m. of the plunger pump.

- Determination of the curve η vs the flow for different r.p.m. of the plunger pump.

- Determination of the map of a plunger pump.

Layout :

- Length - 2.5 m or below

- Width - 1.5 m or below

- Height - 2 m or below

- Weight - Around 500kg

Technical specifications:

- Centrifugal Pump and Second Centrifugal Pump

- A brass-body

- Pedestal or of free axis type

- Stainless steel shaft.

- flow 80 l/min or above

- head 9m or above

- Efficiency is 35% or above

Gear Pump

- Corrosion-resistant bronze-bodied gear pump

- With stainless steel shafts

- Bronze helical gears

- Should quiet in operation

- flow 13.7 l/min or above

- head 40m or above

- Efficiency is 70% or above

Axial Flow Pump

- With propeller, which works in an acrylic casing with thin interstices between the propeller and the casing.

- flow 50 l/min or above

- head 1.8m or above

- Efficiency is 15% or above

Flexible Impeller pump

- Bronze pump head

- Stainless steel shaft and flexible impeller

- flow 60 l/ min at head of 20m or above

Turbine Pump or Peripheral Pump

- With a runner of straight blades inside an annular casing and an axis of activation on two lubricated ball bearings.

- Bronze pump body

- Stainless steel shaft

- flow 24 l/min or above

- head 20m or above

Diaphragm Pump

- flow 5.8 l/min at a maximum head of 30m or above

- Stainless steel wetted parts

Plunger Pump

- Stainless steel wetted parts

- flow 5.3 l/min at maximum head of 60m or above

Instrumentation and controls: All the services and instrumentation for determining the characteristic curves of eight different pumps at different speeds should be supplied For rotodynamic pumps:

- Pressure head vs flow

- Power absorbed vs flow

- Pump efficiency vs flow

For positive displacement pumps:

- Flow vs pressure head

- Power absorbed vs pressure head

- Volumetric efficiency vs pressure head

Computer Control +Data Acquisition+Data Management Software software should be included

- A Compatible computer (PC) should be supplied

- Processor: 7th Gen. Intel Core i5 - 7400 (6MB Cache) 3.0 GHz recommended

- 16GB DDR4 RAM recommended

- 1TB 5400 RPM SATA SSD recommended

- OS: Windows 10 (64bit)

- Keyboard /Mouse

- Ports (recommended specs)

- 4 x USB 3.0

- HDMI-out

- DisplayPort 1.2

- 2 x Thunderbolt 3 (supports Type-C, USB3.1, DisplayPort, PS)

- Gigabit Ethernet, audio out

- Display: 21.5” LED monitor is recommended Components

- Compatible power cord and adapter

- Necessary tool kits, supplementary parts

- Required calibration manuals should be supplied

- Assembly and Installation, Interface and Control Software, Starting-up, Safety, Maintenance, Calibration & Practices Manuals should be supplied

91-9829132777

91-9829132777