Naval Training System

Order Code: NTS-001

Category: Marine Engineering Trainers

PURPOSE OF THE BENCH The aim is to reproduce the operating principle of a steering gear such as it can exist on board a highly automated ship. Train students of all levels to drive and maintain driving an automated system through nominal situations ...

SPECIFICATION

PURPOSE OF THE BENCH

The aim is to reproduce the operating principle of a steering gear such as it can exist on board a highly automated ship. Train students of all levels to drive and maintain driving an automated system through nominal situations or degradations close to reality.

Types of activities in terms of principle of conduct:

- Monitor parameters,

- View conduct configurations,

- Operate interfaces that allow nominal or degraded installation management,

- Identify a functional drift or a malfunction,

- Use driving images to diagnose damage,

- Take conduct rights.

Types of activities in terms of conduct maintenance related to the configuration of the systems:

- 1. Electric type malfunction:

- No or loss of power on type sensors:

- Pressure switch

- Temperature

- Position

- Pressure

- Tank level

- No or loss of power on distributors' coils

- No or loss of power to the motor pump group

- Loss of the circuit breaker, of a relay

- Loss of DEP order or loss of DEP

- No or loss of power on type sensors:

- Mechanical type malfunctions / adjustment fault:

- i. Component type adjustment:

- Pressure limiter

- Sensor

- Line break between sensor and PLC

- Pump regulation

- i. Component type adjustment:

- Bad circuit layout

- Circuit valves

- Degraded components

- Thermal type malfunction

Types of driving maintenance activities related to driving configuration:

- Loss of communication in remote HMI and PLC: Involves the operator to maintain the pipe in the room in automated mode

- Loss of PLC: Involves the operator to maintain the pipe in the room in non-automated mode (subject to keeping the pump running)

- Loss of a switch:

- Involves the operator to maintain the installation pipe through the interface most suited to the situation

2 - TECHNICAL SPECIFICATION

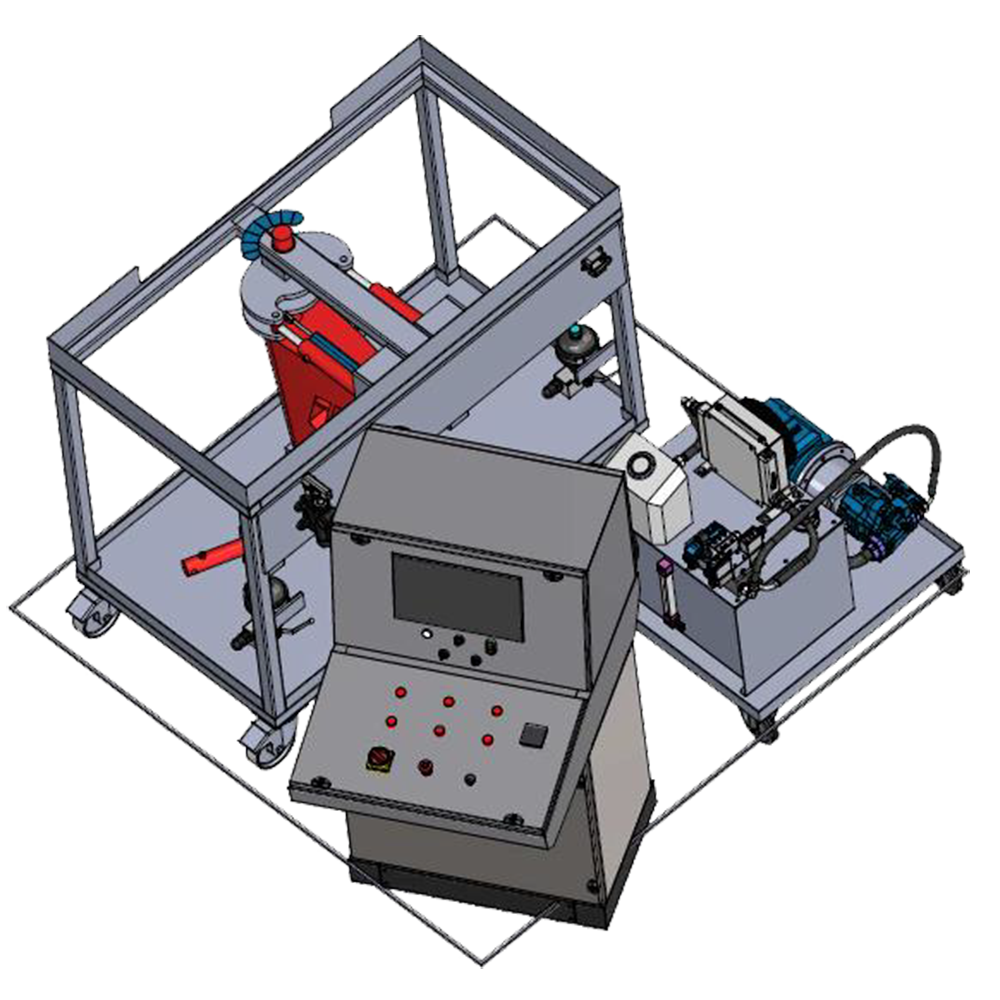

The equipment we offer is an automated and non-automated hydraulic bench composed of three sub-assemblies:

- A hydraulic generation composed of a motor pump group, an oil tank with its retention tank as well as all the hydraulic components and accessories necessary for the operation of the rudder.

- An operative part on a mechanically welded chassis with translucent casing, reproducing a rudder, with its instrumented control jacks, as well as opposing jacks representing the forces exerted by water on the rudder.

- A control console with a power part for supplying the hydraulic generation, a command and control part, with an automaton associated with an HMI forcontrol and display. This desk is also equipped with buttons and indicator lights.

These three assemblies are hydraulically and electrically connected to each other.

The assembly is designed to be installed in a space of 2mx2m excluding the control console.

We only use industrial components from major brands, therefore very widespread, BOSCH REXROTH or EATON VICKERS pump, TOR components Cetop 3 EATON VICKERS, WANFLUH proportional components

91-9829132777

91-9829132777