Nozzle Tester

Order Code: 29653

Category: Automobile Engineering Lab

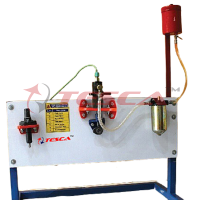

INTRODUCTION · Tesca's new Nozzle Tester, designed & manufactured in India with German standards and quality · Designed for Bs2, Bs3 & Bs4 nozzles · Can test up to 400 bar pressure with a least count of 2 bar...

SPECIFICATION

INTRODUCTION

· Tesca's new Nozzle Tester, designed & manufactured in India with German standards and quality

· Designed for Bs2, Bs3 & Bs4 nozzles

· Can test up to 400 bar pressure with a least count of 2 bar for higher accuracy & precision

· 29653 has been designed for testing injector with over 200 bar opening pressure 29653 avoids vibration and shudder which damages the gauge and generates error with a rigid base plate to add to stability

*Longer and sturdier lever provided for strokes to develop higher pressure in one stroke while also making it user friendly

*Nozzle back leak can be better assessed with 29653

FEATURES & APPLICATION

1. Oil Tank With 5µ Filter

2. Shut-off Valve With Valve Spindle

3. Split Pin

4. Base Plate

5. Manual Operating Lever

6. Warning Notice: "Do Not Reach Into Test Jet"

7. Pressure Outlet (Test Pressure Line Connection)

8. Pressure Gauge (0-400 Bar; LC: 2 Bar)

9. High pressure pipes for connecting the injectors shall also be provided with the unit

The base plate and plastic body provides high rigidity and stability while keeping the weight of the 00000 low. The 5µ filter would reduce metal chips and burrs from blocking the nozzles while testing; improving the quality of testing

Salient Features

· Long effective stroke of the hand lever

· Sufficient pressure build up in one stroke

· Minimum internal leakage

· Low dead volume of the gauge

High Accuracy

· 400 bar readout

· Reduced total error ( / - 2.4 bar) through high read-off (LC: 2 bar) and pressure gauge accuracy

· Idling vibrations of the engine can be avoided by extremely accurate analysis of the smallest possible leaks

Test

· Opening Pressure Test

· Jet Shape

· Tightness of Fitting

· Assembly Tightness

· Chatter Behavior

SPECIFICATION

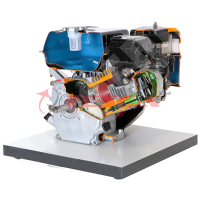

· Testing and adjustment of injection-nozzle opening pressure

· Assessment of the injection spray with regard to shape and atomization (injection-spray pattern) and repetition of the same pattern

· Checking for leaks in injection nozzles, and checking the chatter properties

Technical Data:

For Nozzle Types : P Type, R Type & S Type

Pressure Gauge : 0-400 bar (L.C: 2 bar)

Filter : 5µ

Connecting Thread : M12 X 1.5, M14 X 1.5

Weight : 12 kg

Pressure Gauge

Description -Value

Range - 0 - 400 bars

Least count - 2 bars

Accuracy - ±0.5% of F.S

Test Oil Tank

Description -Value

Test oil tank filling quantity - 600 ml

Filter in test oil tank with precision in line with ISO 4020-2 - 330 000 (approx. 5m)

Tightening Torque

Description - Value

Test pressure line for 29653 - 15 10Nm

Test pressure line to nozzle holder - 15 10Nm

Reduction fitting on nozzle holder - 15 10Nm

Adapter to nozzle holder - 15 10Nm

91-9829132777

91-9829132777