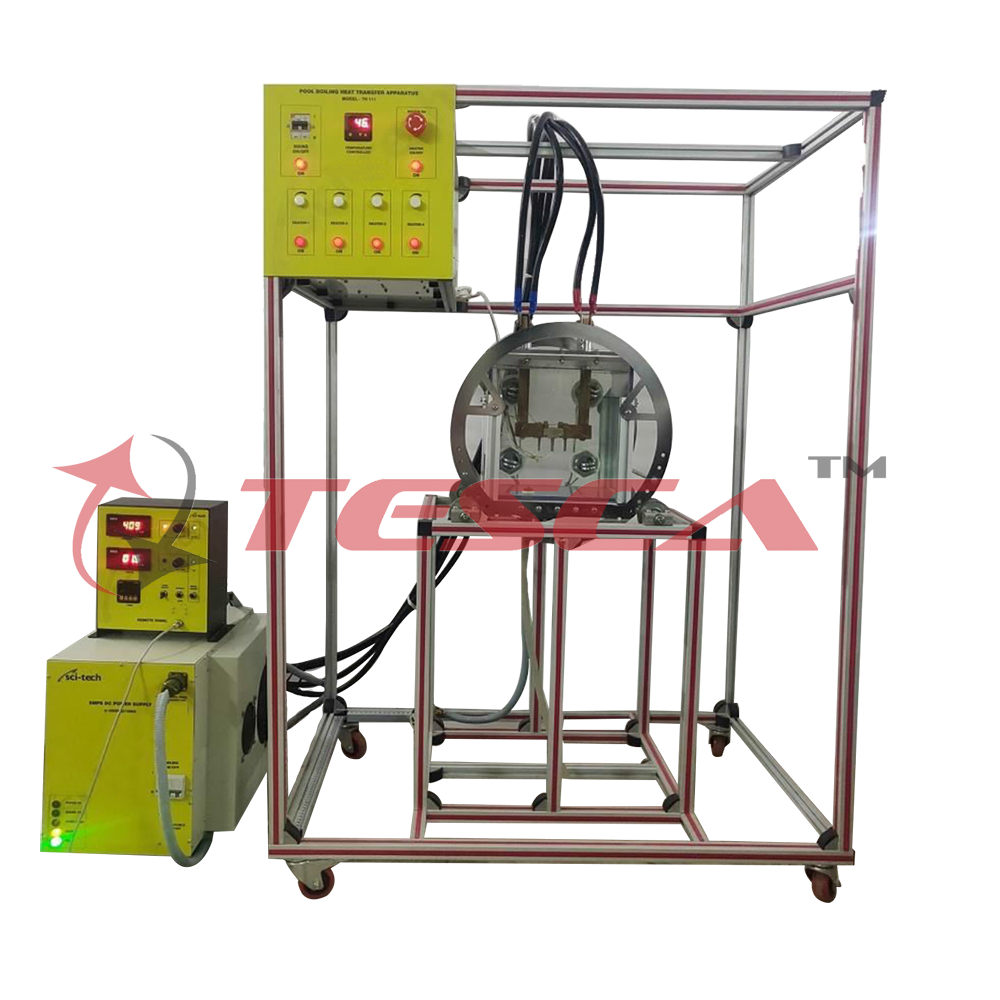

Nucleate Pool Boiling Heat Transfer Apparatus

Order Code: 32365

Category: Thermodynamics Lab

Features Visual demonstrations of convective, nucleate and film boiling. Includes series of safety devices for operator safety. Optional Data Acquisition System with sensors & software. Heating a liquid over a heating surface produces diffe...

SPECIFICATION

Features

Visual demonstrations of convective, nucleate and film boiling.

Includes series of safety devices for operator safety.

Optional Data Acquisition System with sensors & software.

Heating a liquid over a heating surface produces different modes of boiling dependent on the heat flux density. They can accelerate the evaporation process (nucleate boiling) or impair it (film boiling).

In practice, a limitation of the heat flux density must be assured in order to prevent damage to the heating surface. This knowledge is applied in practice e.g. when designing steam boilers for steampowered drives.

Tesca Nucleate Pool Boiling Heat Transfer Apparatus 32365 experimental unit can be used to demonstrate boiling and evaporation processes in a straightforward manner. The processes take place in a transparent tank. A condenser in the form of a water-cooled tube coil ensures a closed circuit within the tank.

Sensors record the flow rate of the cooling water, the heating power, pressure and temperatures at all relevant points. The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included.

Tesca Nucleate Pool Boiling Heat Transfer Apparatus 32365 has been designed for students demonstrations on convective, nucleate and film boiling. The unit mainly consists of a thick walled glass cylinder fitted internally with a heating element and a coil type condenser.

Instrumentations are provided for the measurement of temperature, pressure, flowrate and power.

The unit helps students to understand better the heat transfer processes from a hot region to a colder one in countless industrial applications, e.g. thermal and nuclear power generation in steam plants, refrigeration, heat transmission, etc. locally warmed liquid expands and convection currents carry it to the liquid-vapour interface where evaporation takes place and thermal equilibrium is restored. Thus, in this mode, evaporation takes place at small temperature differences and with no bubble formation.

Tesca Nucleate Pool boiling heat transfer apparatus 32365 is used to calculate critical heat flux (CHF) of the test specimen. Critical heat flux (CHF) is an important criterion in nuclear reactor safety and the efficiency of boiling heat transfer. This parameter is known to be dependent of the surface roughness and the wettability of a material that is in contact with boiling fluid. Generally, CHF enhances with increasing surface roughness and wettability.

The unit comprises of pool boiling chamber made of polycarbonate equipped with water heater, copper blocks, PEEK insulation block, copper electrodes & test specimen.

For calculating CHF of each test specimen, unit comes with DC power supply of 10volts DC @ 1200A, for supplying power to specimens through copper electrodes inside pool boiling chamber.

For analyzing data and controlling voltage of power supply, DAQ device is available with data acquisition software which can connect to laptop/computer via USB cable.

For controlling heater power, regulator is mounted on panel, and for visualizing power supply data, remote control is available & to change power manually via potentiometer.

Specimen Sample preparation: Test specimen samples are of two types of same grade stainless steel 304L (certified) as NS (Non treated specimens) & OS (oxidized specimens). The non-treated specimen are mechanically polished using different grades of ultrafine sandpaper (i.e. 320, 600, 800) in order to have three types of NS specimens. The oxidized specimens are prepared as follows: non treated specimen are put into a furnace set to target temperatures of 300, 450 & 600 degrees C, respectively, and gradually heated up. The average heating rate are about 2-2.5° C/sec and the furnace is maintained at a given temperature condition for 10min, and then slowly cooled down to about 30° C, the average cooling rate was about 23° C/min. Finally, three kinds of oxidized test specimens obtained as minimum furnace temperature of 300° C and higher furnace temperature of 600° C. All test specimens as NS (fresh) non treated & OS oxidized surface.eg OS-SP320(450° C) indicated test surface grounded with grade-320 sandpaper & oxidized at 450° C. eg, as B-SP320 indicated test surface grounded with grade 320 sandpaper.

Detailed Operation & Maintenance Manual is provided along with the trainer.

Specifications

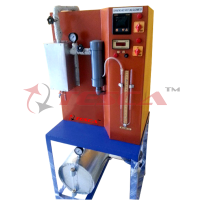

1. Visualization of boiling and evaporation in a transparent pressure vessel

2. Evaporation with heating element

3. Condensation with tube coil

4. Safety valve protects against overpressure in the system

5. Pressure switch for additional protection of the pressure vessel, adjustable

6. Sensors for pressure, flow rate and temperature with digital display

7. Optional software for data acquisition via USB under Windows

Screen Shot of Data Logging

Pool Boiling Chamber

Technical Specifications

Pool Boiling Chamber: Material: Polycarbonate Thickness: 1.5mm Dimensions: 300x300x300mm

Top Cover: Acrylic, 10mm thickness

Heaters:

Type: ‘U’ Cartridge type

Number of Heaters: 2 x 1000W & 2 x 500W Power: 3000W, continuously adjustable Test Section:

Two Copper blocks: As per drawing Test Section Drawings Two Copper Covers: As per drawings

Test Section Drawings

Insulation block: Material Polyether Ether Ketone (PEEK), as per drawing.

Two Copper Covers: As per drawings.

Test Section

Test Sample: As per drawing, in SS304L DC Power Supply:

Voltage: 10V DC Current: 1200 Amps DC Rating 1200 Watts max

Connections: Flexible suitable cable to pool boiling unit. Connection to pool boiling unit through copper rods @ 10mm dia.

Measuring ranges

Tank pressure: 0…40bar abs.

Power of heater: 0…3000W

Flow rate (cooling water): 1L…15L/min

Temperature monitoring & reading: 4 x 0…100°C

Software screenshot

DAQ Interface:

Make: National Instruments 8 Channel Data Logger Interface & Sensors

Data monitoring & tabulation Voltage, Current, Temperatures Windows 7 or higher

Excel sheet screenshot

Recommended:

High speed video (HSV) camera: Phantom VEO 410L

Specifications: https://www.phantomhighspeed.com/Products/Phantom-VEO/VEO-410L-41

Lens: Nikon AF Micro-Nikkor 105mm f/2.8D

Specifications: https://kenrockwell.com/nikon/105af.htm#spex

Example for HSV images

A B C D E

A. Nucleate boiling – ONB

B. Nucleate boiling – 60% CHF

C. Nucleate boiling – 95% CH

D. Partial film boiling – CHF

E. Film boiling

Experiment Capabilities:

Visualization of different forms of evaporation

Free convection boiling

Nucleate boiling

Film boiling

Heat transfer

Effect of temperature and pressure on the evaporation process

Services Required

Specimen Experimental images

Electric Supply 220 - 240 V AC, 16 A, Single Phase, & 380 – 440V AC @ 20A, Three Phase Earthed.

Water Supply, Drain

91-9829132777

91-9829132777