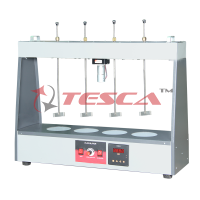

Orbital Shaking Incubator - Heating and Cooling Capacity to hold 500 ML X 16 Flask

Order Code: MT647

Category: General Equipment's

Features: Exterior boy is fabricated from Mild Steel Material, which is powder coated in attractive shades. Interior chamber is fabricated from Mirror polished Stainless Steel S.S. ? 304 Material Outer double walled metal door with sponge ?...

SPECIFICATION

Features:

- Exterior boy is fabricated from Mild Steel Material, which is powder coated in attractive shades.

- Interior chamber is fabricated from Mirror polished Stainless Steel S.S. ? 304 Material

- Outer double walled metal door with sponge ? type silicon gasket for air?tight sealing as to avoid leakage of chamber uniformity

- Electrical wiring as per CE Compliances ? with individual numbering of each internal circuitry wire for ease of maintenance & Repairing

- Chamber illumination is accomplished by Fluorescent light with door switch.

- Cord wire duly tested and inspected with stress factor as per CE standard

- Electric Motor of blower located at the back side of unit, which is protected with safety cover to avoid accident

- Standard motor of reputed companies ? such as CG, GODREJ or GE Make

- User friendly and tactfully designed chamber door and locking mechanism

- Aesthetic outer appearance and high quality

- Unit mounted on castor wheels for easy movement.

- Interchangeable S.S. tray with spring loaded S.S. Lotus clamps for holding Erlenmeyer flasks. (Supplied without flasks)

- Supplied complete with Digital Timer

Air Circulation:

Temperature is maintained by a quiet running blower for better air circulation throughout the chamber. Forced air circulated vertically down and re?circulated throughout the chamber for uniform temperature distribution.

Heating & Cooling System:

Long lasting U?Shaped tubular heaters used as heating element. Hermetically sealed compressor CFC free compressor (134 A gas) coupled with evaporation coil and condenser.

Pre-installation mandatory requirement: (Guarantee void in case of non compliance):

An operator shall maintain Room temperature around machine preferably at 25 °C with air conditioning system or shall arrange for a well ventilated room with exhaust fan. However, surrounding temperature should not exceed 30 °C .

Stabilized Input Voltage of 230 Volt, 50 Hz, 20 Amps, AC Supply must be available for error less performance of the instrument. Use of Servo Controlled Stabilizer is recommended.

|

Technical Specification |

|

|

Construction |

Double walled |

|

Interior |

S.S. 304 Grade mirror polished Stainless steel material |

|

Exterior |

CRC Powder Coated |

|

Inner working size |

145 x 45 x 62 mm (H x W x D) |

|

Chamber volume |

400 Liters |

|

Thermal Insulation |

PUF insulation to avoid thermal loss |

|

Insulation thickness |

75 mm |

|

Temperature Range |

5 °C to 60 °C |

|

Temperature Resolution |

0.1 °C |

|

Temperature Accuracy |

± 0.1 °C |

|

Temperature Uniformity |

± 0.2 °C |

|

Temperature Control |

Micro processor based Auto tune PID Controller |

|

Temperature Display |

LED Display |

|

Temperature sensor |

High quality PT 100 Sensor |

|

Illumination |

Fluorescent Tube light (Make : GELCO) |

|

Fluorescent light watts |

11 Watts |

|

Heating source |

U shaped S.S. Tubular heaters |

|

Shaking |

Achieved by PMDC motor with DC Drive |

|

Motor RPM |

50 -250 RPM (Shaking speed) |

|

Motor speed display |

Digital RPM Indicator (Shaking speed display) |

|

Speed control |

By Rotary Potentiometer |

|

Shaking racks |

16 flasks of 500 ml |

|

Shaking racks material |

Manufactured from polished stainless steel material S.S. 304 Grade |

|

Blower |

Forced Air circulation for uniform temperature distribution |

|

Motor of Blower |

Marathon/GE/Any other reputed make |

|

Refrigeration |

CFC free EMERSON compressor utilizing R 134a eco friendly refrigerant |

|

Observation |

Inner transparent acrylic door for quick viewing and retrieval |

|

Door lock |

Ergonomic and secured key lockable door lock |

|

Feet On |

Castor wheels (For easy mobility) |

|

Electrical |

230 Volt, 15A, 50 Hz, AC Supply |

91-9829132777

91-9829132777