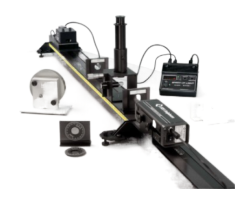

Pneumatic & Electro Pneumatic Training Work Bench

Order Code: 23246435.12

Category: General Lab Equipment II

Technical Features Air filter, Regulator and Lubricator unit (FRL Unit) Pressure Manifold with Four ON/OFF Valves for multiple connections Single Acting Pneumatic Cylinder (Spring Return) Double Acting Pneumatic Cylinder 5/2 way R...

SPECIFICATION

Technical Features

- Air filter, Regulator and Lubricator unit (FRL Unit)

- Pressure Manifold with Four ON/OFF Valves for multiple connections

- Single Acting Pneumatic Cylinder (Spring Return)

- Double Acting Pneumatic Cylinder

- 5/2 way Roller Valve

- 3/2 way Roller Lever Operated Valve

- 3/2 Palm Operated Valve

- 5/3 way Hand Lever Valve

- 5/2 way Single Pilot Spring Return Valve

- 5/3 way Double Pilot Spring Centerd Valve

- Quick Exhaust Valve

- 3/2 way Disc Rotary Valve

- 5/2 way Push Button Valve

- Flow Control Valve

- 3/2 way Pilot Operated Valve

- 5/2 way Push Button Valve

- AND Valve

- Shuttle Valve

- 5/2 way Hand Lever Valve

- 3/2 Hand Lever Valve

- PU Tubings (for quick connections)

- Detailed Instruction manual

- 4/2 way solenoid operated (24V DC) valve: 2 Nos

- 4/3 way solenoid valve

- 24V DC regulated power supply for the kit

- I/O Box: 2 Nos

- Relay: 2 Nos

- Indicator unit and distributor, electrical: 2 Nos

- Limit switch, electrical, left actuated: 4 Nos

- Limit switch, electrical, right actuated: 2 Nos

- Signal Input, electrical

- Set of Cables

- Plug in adapters

- Pressure Relief Unit

Standard Accessories

- Air Compressor. Type: Piston

- Maximum Pressure: 10kg / Cm2

- Capacity: 45 Liters

- Compressor: 1/2 HP

- Motor: 3 HP Single Phase Ac Motor

- Design and function of a Elctro Pneumatic systembasic

- Function and identification of Electro-pneumatic components and their symbols

- Direct and indirect manual controls, stroke dependant controls, time dependant with time delay valves and pressure dependant controls with pressure sequence valves

- Logic AND/OR function to start signals

- Application and fault findings to Electro Pneumatic controls

- Pneumatic Power Section - Electric Control Section

- Provides a modern trainer with components

- Empower's user to design their own circuits

- The components are capable of being mounted on an appriopriate profile plate with grooves for secure and flexible positioning so that the components can be clamped firmly, quickly and safely through quick fix adapters or any suitable component fixing arrangement

- Ensures flexibility in conducting experiments through varies exercises

- Pneumatic Plug in type flexible connectors are safe and alright, usage for multiple applications. Precision quick connector for plastic tubing 4 mm x 0.75 and for internal or external diameter calibrated tubes

- Multifunctional electro - connectors for 4 mm laboratory plugs and jack plus"

91-9829132777

91-9829132777