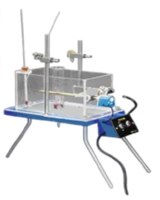

Power Generation Trainer

Order Code: 21225373.2

Category: General Lab Equipment I

Specifications: Facilitates study of regulation methods & determination of subtransient reactance ofgenerator. Generation Trainer need a few set of associated panels (7-8 nos. typically) which are mounted in a light weight stu...

SPECIFICATION

Specifications:

- Facilitates study of regulation methods & determination of subtransient reactance ofgenerator.

- Generation Trainer need a few set of associated panels (7-8 nos. typically) which are mounted in a light weight sturdy aluminum profile flat demo panel system.

- Facilitates easy and safe wiring by students due to use of 4mm sturdy Shrouded banana patch cords and shrouded socket arrange-ments for high voltage circuits

- Each panel has ABS molded plastic sturdy enclosure, and colorful screwless overlays showing circuits diagrams & its connection tag numbers for easy understanding and connection.

- Useful for Under Graduate Practicals & Post Graduate projects.

- Set of Instructor Guide & Student Workbook.

Technical

Resource Panels needed :

Input 3 phase DOLstarter panel (EMT 1)

- 4 pole MCB of 415V/2A.

- DOL9AContactor with 230/50Hz/11VACoil.

- Bimetallic thermal O/Lrelay with range 1.4A-2.3A.

- R-Y-B Input Indicators. MFWD/REV, Star-Delta starter panel (EMT 4)

- FWD/REV, 3 pole 3 way switch with center OFF, 6A/440V.

- Star/Delta switch 3 pole, 3 way with center OFF, 6A/440VMInstrumentation Power supply cum Multichannel DPM panel (EMT 8)

- +/-12 V, 500 mA,

- +5V, 300mA,

- Unregulated 17V dc/750 mA,

- Line synchronizing signal.

- Multichannel DPM for digital display of torque, speed etc.

SCR Actuator (variable DC) cum sensor signal conditioning panel (EMT9) x 3 nos.

- Full bridge SCR based 0V-195V / 5 Amp cosine firing with linear charateristics.

- Supports signal conditioning circuit for speed, torque in kg wt to output 0-2.5Vdc(FS).

- 3 Nos. of these supplies required for DC Armature, DC motor field and AC generatorfield. Rotor Resistance cum 3 phase Synchronous Motor Control Panel (EMT 5A/5B)

- Rotor resistors of 30E/5Awith 3 taps of 0E, 15E, 21E, 30E each 3 nos

- Rotor resistor selector switch, 3 pole, 6 Way, 6A/440 V.

- DC Rotor excitation over current relay (3Amp)

- DC voltmeter and DC ammeter panel (EMT 6A/6B)

- DC voltmeter (0-300V)

- DC Ammeter (0-5A) with polarity protection diode

- Field failure relay to control Armature supply. Both 6A/6B needed simultaneously.

Integrated AC 3 phase measurement panel (EMT 34)

- Consist of (96 X 96 mm) Digital meters for 3 phase. Measures V, I, PF (0.2 lag – unity 0.2 lead), Hz. Hence separate analog wattmeters (3 ph., 1ph. ) are not needed.

- 1 ph. Motor, Alternator & Sync. Motor Panel (EMT 16)

- 14 Shrouded Banana

- 1 ph. MCBs of 4A/1.6A 1 each.

- 2 no. 2P2W selector switches to run as 1ph. alternator then as synchronous motor.

- 8A push button switch to simulate as centrifugal switch.

Resistor Load Panel (EMT14A/B)

- AC Resistors : 10K / 5K / 3.5K / 2.5K / 2K / 1.5K / OFF 200W x 3 phases / 6 taps

- DC Resistors : 750E / 600E / 300E / 212E / 162E / 125E / 112E / 100E / 400W / 8 taps + OFF + separate 60E tap for DC series Gen.

LC Load Panel (EMT 15A/B)

- Inductive load : 0.15H / 0.3H / 0.45H / 0.6H / 0.75H / 1.5H / 3H /400mAX 3Nos

- Capacitive load : 1.25μF/2.5μF/5μF/415VX 3Nos.

Table Top Panels, M/C's Key Resource :

- Trunnion mounted DC integrated machine 300W coupled to 3 phase

- Salient pole alternator, 300VA, 415VAC, 50Hz

List of Experiments :

Regulation of 3 phase alternator by :

- Synchronous impedance method,

- ZPF or POTIER method,

- Actual load test

Determination of :

- Direct axis and quadrate axis subtransient reactance Xd" & Xq”

- Zero sequence reactance X0.

- Negative sequence reactance X2.

91-9829132777

91-9829132777