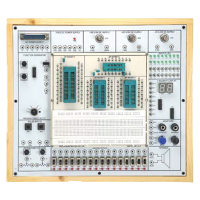

Process Automation Fully Modular Assembly Training System

Order Code: 20214003.5

Category: General Lab Equipment II

Specifications: The system should cover the following training contents (like or better than or Equivalent) Planning and construction of different process applications. Planning and construction of different automation solutions for the cont...

SPECIFICATION

- Specifications:

- The system should cover the following training contents (like or better than or Equivalent)

- Planning and construction of different process applications.

- Planning and construction of different automation solutions for the control systems.

- Familiarisation with the design , function and behavior of industrial automation components.

- Commissioning and optimization of automated process applications.

- Making process connections (via pipes/hoses) , connecting up the electricity supply.Fundamentals of the use of data acquisition , system control.

- Setting up a level , flow control loop.

- Comparison of different sensors for level measurement.

- Level control against trapped-air cushion.

- Level / flow cascade control.

- Planning , setting up, testing , optimizing and assessing pressure , temperature control loops.

- Technical terminology and symbols in industrial control engineering.

- Functional range of a digital process controller.

- Configuration , parameterization and operation via keyboard.

- Programming a PLC using included programming software.

- Modbus communication.

- Functional range of an electro-pneumatically operated control valve.

- Principle of an electromagnetic flow sensor.

- The system must include the following stand-Alone Components:-

- Base module for the modular setup of the different process Experiments Power control unit module.

- Module of Stainless steel storage tank 70 L.

- Module for Centrifugal pump with flow rate 4 m3/h , 15m head.

- Compressed air 6…..10 bar.

- Module for Manometer :0….10 bar.

- Module for Rotameter 0 ….2.5 m3/h.

- Module include 2 pressure tanks with safety valves 3 L.

- Air Heat controlled Muffle Furnace.

- Heater Module 2kw with thermostat and dry-running protection.

- Thermometer at heater outlet :0….100 c.

- Continuous controller module.

- Switching controller module.

- PLC module with software.

- Control valve as actuator in control loop.

- Actuator drive.

- Elecrto -pneumatic positioner.

- Control valve , pneumatically driven, kvs 1.0.

- Control valve , electrically driven , kvs 0.4.

- Control valve , electrically driven , kvs 1.0.

- pressure sensor , 0…6 bar.

- pressure sensor , 0….2 bar.

- pressure sensor, 0….90 bar.

- Orifice with differential pressure sensor.

- Flow rate sensor 0….2 m3/h.

- Level sensor , capacitive.

- Temperature sensor.

- Thermocouple.

- Digital display.

- Visualisation software.

- Modbus module for controller.

- Modbus module for PLC.

- Software for controller configuration.

- PC computer (Brand Name)Core i7 , 8 GB Ram , 1 TB HDD with 18.5" LED

91-9829132777

91-9829132777