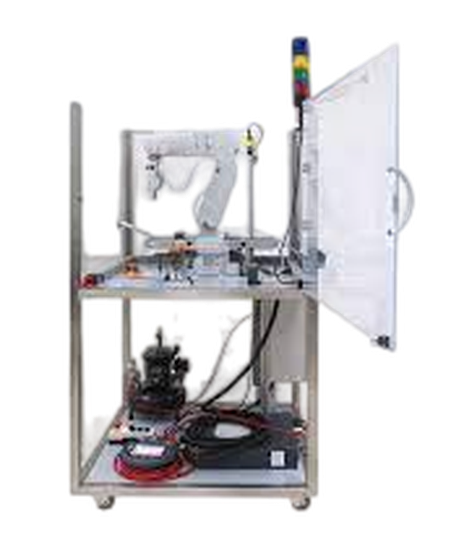

ROBOT STATION WITH ARTIFICIAL VISION SYSTEM

Order Code: 22235741.49

Category: General Lab Equipment II

The Modular Industrial robotics unit shall be assembled on a special closed structure in compliance with industrial safety standards for the application of artificial vision systems; Where, the robotic station carries out the assembl...

SPECIFICATION

The Modular Industrial robotics unit shall be assembled on a special closed structure in compliance with industrial safety standards for the application of artificial vision systems;

Where, the robotic station carries out the assembly of five elements. The unit consists of a six -axis industrial robot equipped with a gripper (electrical or pneumatic) with parallel fingers.

The loading of the pieces can take place from a conveyor and / or from a rotary table. Both are managed by the robot controller .

- The station is composed of an aluminum profile structure inside which the robot controller is placed. The entire working area is protected by poly -carbonate transparent panels TRAINING PROGRAM:The training program includes the following topics:

- Structure of a six -axis robot

- Robot operation analysis

- Movement technique analysis

- Control software analysis with specific emphasis on: - Movement algorithms - Self learning

- Industrial robot applications

- Artificial vision

- Calibration

- Movement resolution

- Load capacity, speed

- Safety

- Programming the controller

- Using the teach box ROBOT CHARACTERISTICS The robot has 6 degrees of freedom, as follows: Base: Movement range: ±240°; Max speed: 225°/s Shoulder: Movement range: ±120°; Max speed: 150°/s Elbow: Movement range: 0° ÷160°; Max speed: 275°/s Bottom arm: Movement range: ±200°;Max speed: 412°/s Wrist torsion: Movement range: 1 57 | P a g e Mechatronics Lab_2022 ±120°; Max speed: 450°/s Wrist rotation: Movement range: ±360°; Max speed: 720°/s Repeatability precision: ±0.02 mm Maximum load: 3 kg; wrist downward Motors: AC Servomechanisms Position detection: absolute encoders

- ROBOT CONTROLLER Processor type: 64 -bit RISC main CPU with EMERGENCY OFF security functions and door opening sensor. RJ 45 interface for PC programming. 32 digital inputs / 32 digital outputs.

- ARTIFICIAL VISION SYSTEM Sensor: 1.3” CCD Resolution (pixel): 640 x 480 Electronic shutter speed: 16 µs → 1000 ms Memory: Work/Program: 64 MB Flash Process image: 128 MB Communication: Ethernet Port 10/100 T Base

- TOUCH SCREEN PROGRAMMING KEYPAD

- CONVEYOR -100 W

- Dimensions: 730 x 80 x 120 mm Servo drive: AC Safety SSCNET

- VISION AND ROBOT SOFTWARE

- Easy and advanced programming languages specific for robotic Applications with artificial vision. O.S.: Windows 7, 32 bit version

- Power supply: 230 Vac 50 Hz single phase (Other voltage and frequency on request)

- Dimensions: 1100 x 800 x 1950 mm

- Weight: 100 K

91-9829132777

91-9829132777