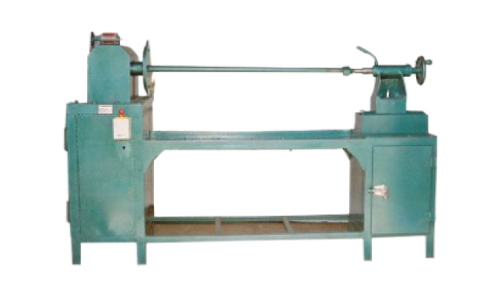

Semi Automatic LV Transformer Coil Winding Machine

Order Code: 21224942.2

Category: General Lab Equipment II

Scope of Works: Supply, Delivery, Installation, testing and commissioning of semi automatic LV coil machine all complete set for Distribution transformer machine. &nb...

SPECIFICATION

Scope of Works:

- Supply, Delivery, Installation, testing and commissioning of semi automatic LV coil machine all complete set for Distribution transformer machine.

Winding Head:

- The winding head shall be of heavy duty welded steel structural head with open type construction with direct driven heavy duty geared motor with reduction Ratio 47.29:1 at service factor 2.58 or suitable reduction ratio or service factor for continuous duty cycle for 3 shift at maximum speed of 1440 RPM to achieve 30 RPM as an output on main spindle shaft.

Winding Motor:

- The motor shall be heavy duty reduction geared with inbuilt break system of reputed make.

Motor Controller:

- It shall consist of variable frequency drive of 3.0 H.P., 3 Phase input and 3 Phase output. It shall be of Yaskawa type or equivalent.

Tailstock:

- It shall be heavy duty sliding pneumatically operated tailstock with revolving center.

Distance between Centers:

- The distance between centers shall be minimum of 200 mm and maximum of 1400 mm from face plate to tailstock center.

Conductor:

- The sizes of the conductor generally used are: ROUND: 0.80 mm to 4.0 mm STRIP : Min 3 x 1.5mm to 15 x 5 super enameled copper strips.

Coil Swing Diameter:

- Open type

Distance from the base:

- It shall be 1000 mm from the base frame.

Winding Speed:

- It shall be 0.05 to 50 rpm continuous variable. Winding Width: The winding width shall be upto 800 mm

Coil Weight:

- The coil weight shall not be less than 200 kg excluding mandrill weight.

Tensioner:

- It shall be mechanical type with adjustable tension.

Control console:

- It shall consist of programmable up down counter with 360 PPI encoder feedbacks counter with LCD and LED Display.

Pressure Controller:

- Dual Pressure roller system shall be provided from the bottom side of the coil with a pivoting head which allows the roller to change the angle and apply more pressure for better tension and tight winding. The system shall be operated by pneumatic cylinder.

Safety Devices and protection covers:

- Machine shall have all required safety devices to make safety towards operator side duringrunning. Spares and consumables:Set of all consumables for one year shall be provided along with the machine.

- Power Supply:400 V, 3 Phases, 50 Hz

91-9829132777

91-9829132777