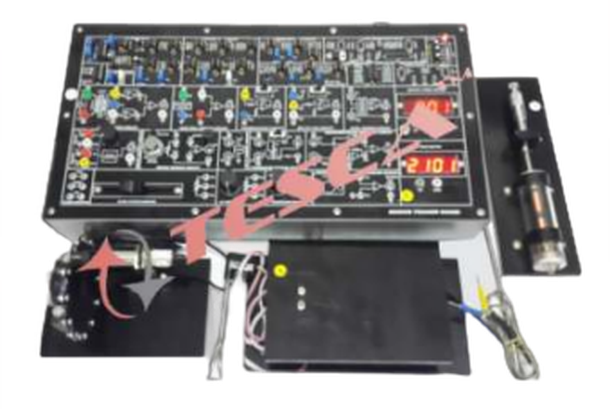

Sensor Trainer Kit

Order Code: 22235741.67

Category: General Lab Equipment II

Objectives:- To study working principle of different types of Sensors (transducers) To study signal output & signal conditioning circuitry different types Sensors (transducers) Technical Specifications: SS Steel, & DC Regul...

SPECIFICATION

Objectives:-

- To study working principle of different types of Sensors (transducers)

- To study signal output & signal conditioning circuitry different types Sensors (transducers)

Technical Specifications:

- SS Steel, & DC Regulated Power Supplies

- +5VDC(fix) for LVDT

- +5VDC(fix) for Thermocouple

- +5VDC(fix) for RTD

- +5VDC(fix) for Strain Gauge & Load Cell

- +5VDC(fix) & 0-12VDC(variable) for Speed Sensor circuit &

- +9VDC(fix) & +5VDC(fix) for Smoke Sensor Circuit

- +5VDC(fix) for all DPMs

Must Include:

- Separate mechanism for LVDT (LVDT Jig) with 5 pin connector, is provided, to be connected at "LVDT INPUT" connector provided in its signal conditioning circuit

- Separate speed sensor, is provided, to be connected at "SPEED SENSOR INPUT" connector provided in "SPEED SENSOR "circuit

- Separate smoke sensor, is provided, to be connected at "SMOKE SENSOR INPUT" connector provided in "SMOKE SENSOR ALARM" circuit

- Separate Load Cell & Strain Gauge sensors, are provided, to be connected at "A,B,C & D" sockets provided in its circuit

- Separate Thermocouple sensor (K-type) & RTD(PT-100) sensor along with their associated accessories, are provided, to be connected at "THERMOCOUPLE INPUT" & at "RTD INPUT" sockets respectively provided in their signal conditioning circuits

- Three nos. of Digital Panel Meter (DPMs) are provided on front panel in their respective circuits for observing direct output of the respective experiments. One DPM fitted separately (provided with INPUT sockets "+" & "-") at top right corner can be used both for Thermocouple & RTD experiment with the help of "THERMOCOUPLE RTD" toggle switch

- Circuit diagrams for different experiments are printed on front PCB panel & important Test Points (TPs) are extended to the front panel

- Glass Epoxy PCB used as front panel of 458mm x 458mm & mounted on shock proof wooden box

- Power requirement: 220V ac +10%, 50Hz

91-9829132777

91-9829132777