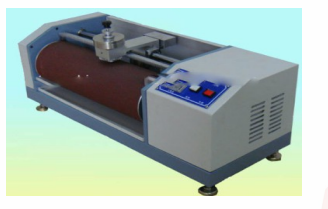

Soling materials abrasion machine

Order Code: 23246708.1.1

Category: General Lab Equipment II

Soling materials abrasion machine designed to test rubber and urethanes to assess their resistance to abrasion in normal everyday wear. The main function of the abrasive tester is to test the friction of the surface by a particular piece of sandpaper...

SPECIFICATION

Soling materials abrasion machine designed to test rubber and urethanes to assess their resistance to abrasion in normal everyday wear. The main function of the abrasive tester is to test the friction of the surface by a particular piece of sandpaper, after friction for a certain time, and then assess the condition of the material surface, weight, volume, and thickness, from this standard to assess the abrasive nature of materials. A 150mm diameter drum is rotated at 40rpm by a precision AC motor with variable speed control.

- A sheet of specified P60 abrasive paper was fixed to the drum with double-sided adhesive tape.

- A cylindrical sample, of fixed dimensions, is inserted in the sample holder and its protrusion is adjusted and set using the integral micrometer. The sample holder either fixed or rotating travels over the surface of the abrasive paper at 0.32m/sec under a loading of either 5 or 10 newtons for a set distance. An adjustable rotary cam allows the sample to travel 10, 20, 30, and 40 meters. The machine should have a self-tracking suction head that can be connected to a standard vacuum cleaner, removing the need for constant operator attention. A sample cutting knife should be provided and suitable for use with

-A rotary pillar drill,

-Test-arm weight: ± 5 (g)

-Specimens size: Φ16±0.2mm

-6-14mm (thickness)

-Specimen load: 2.5N, 5N, 10N

-Shift screw: 6 teeth/inch

-Horizontal displacement: 4.2mm / rotate,

-Fixture lateral displacement: 4.2mm/wheel each lap,

-Wheel diameter: 150mm±0.2, Wheel length: 460mm,

-Wheel rotate speed: 40±1r/min, Travel reservations: 40m/20m,Grinding Wheel: # 40,

-Testing length: 40M (about 84 rotate), Set rotation: 84 rotate (about 40M),

-Abrasion speed: 0.32m/sec, Dip angle: 3° the angle of the specimen back shaft with vertical roller face,

-Testing angle: 15° (adjustable),

-Emery paper: 60 #, 425 ±473 ±1.5 to 2 (mm),

-Dimension:(70 ×450 ×450) cm,

-Machine weight: 60 to 75 Kgs,

-Counter: LCD displayer 6-digit auto-brake device,

-With an automatic steel cleaning brush wheel,

-Power Supply: AC 220±10%, 50Hz/ 60Hz,

-Drive Power: 40W; 1/30,

-Power consumption:400w,

-Return form: Electric automatic reset.

-Consumables: Certified rubber: The certified abrasion rubber is used to check the abrasion machine is performing correctly.

-A single sheet (186mm x 186mm x 8mm) rubber. Abrasive Paper: a standard 60-grit abrasive paper specifically for the abrasion test machines.

-A single sheet (473mm x 400mm) abrasive paper.

- General requirement: this equipment is used to assess the abrasion of elastomers subject to wear by abrasive action. The abrasion machine is basically consist of three a laterally movable test piece holder and a rotatable cylinder to which a specified abrasive paper is fixed. The test piece holder is consist a cylindrical opening, the diameter of which can be adjusted, and has a device for adjusting the length of the test piece protruding from the opening to 2mm.The test piece holder is mounted on a swivel arm, the center axis of the holder has an inclination of 3oc to the perpendicular in the direction of rotation and the center of the test piece to be abraded shall lie within 1mm directly above the longitudinal axis to cylinder. The test piece will be pressed against the abrasive cloth with a force of 10N and the lateral displacement is approximately 4.2mm per revolution of cylinder so that the test piece shall traverse only four times across the same area of the abrasive cloth. The test must automatically stop at the end of the abrasion distance. Consumable: Abrasive paper: grain size 60, at least 400mm wide, 473 mm long and 1mm average thickness shall be used as the abrasive medium. The abrasive surface causes a mass loss between 180mg and 220mg for an abrasion distance of 40m.Standard Rubber, in accordance of Dimension: 183x183 mm, Thickness minimum 8mm. Accessories: Cutting die /hollow drill, Cylindrical in shape, of diameter 16mm ± 0.2mm, with a minimum height of 6mm, Analytical Balance: Accuracy ±1mg, capacity 1kg.

91-9829132777

91-9829132777