Training Equipment In Industrial Pneumatics

Order Code: 22235575.1.130

Category: General Lab Equipment I

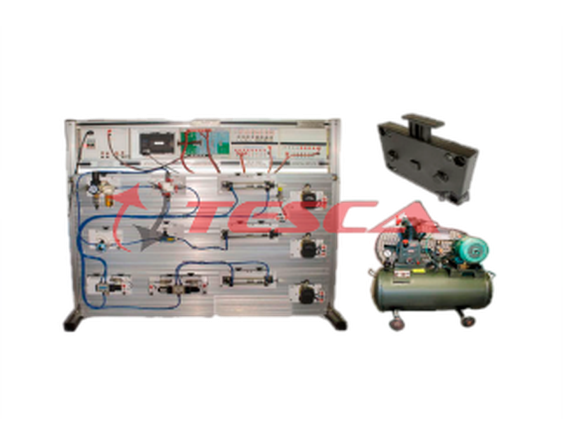

Training system: pneumatics, electropneumatics and PLC Complete training system providing an experimental introduction to the fundamentals of pneumatics and electro-pneumatics, also with PLC Features - complete training system providing an experim...

SPECIFICATION

Training system: pneumatics, electropneumatics and PLC

Complete training system providing an experimental introduction to the fundamentals of pneumatics and electro-pneumatics, also with PLC

Features

- complete training system providing an experimental introduction to the fundamentals of pneumatics and electro-pneumatics - with PLC

- experiment scope and configuration based on the tried and proven concept course developed by the BIBB; Federal Institute for Vocational Training

- 2 large-format metal assembly panels for fast,secure component mounting

- Sturdy base construction, mobile, with drawer system for storage

Learning objectives/experiments

- physical principles of pneumatics and electro-pneumatics

- fundamentals of, and terms used in, process control

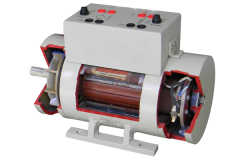

- design and function of pneumatic components

- logic elements, logic diagram

- multi-way valves, pressure, shut-off and flow control valves

- controls with starting and setup conditions (automatic/manual/jog mode)

- controls with boundary conditions

- routing and time controls (process and time controlled sequencers)

- position-dependent controls

- troubleshooting and commissioning

Specification

[1] comprehensive trainer for demonstration and exercises in pneumatics, electropneumatics and PLCs

[2] 2 perforated metal panels for quick component fixing

[3] standard industrial pneumatic and electropneumatic components

[4] various multi-way valves, pressure, shutoff and flow control valves

[5] electric limit switch, various proximity switches, solenoid valves, signal board

[6] PLC with programming software

[7] integrated power supply unit to supply the electro-pneumatics and the PLC

[8] 2x maintenance units + distributor block for simultaneous use of both panels

[9] hoses, cables and tools to construct the experiments

[10] compressor for compressed air supply, esp. silent

Technical data

2 assembly panels, LxH: 1100x700mm each Compressor

- noise level: approx. 45db

- tank: 24L

- intake capacity: 50L/min

- power output: 32L/min at 8bar

- max. pressure: 8bar

- motor: 0,34kW

PLC with display

- inputs: 8

- outputs: 4

- EEPROM

- programming software

Size of components: nominal width 3

Pneumatic hose: 4/2mm

Power supply unit: 24VDC, 4A

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

91-9829132777

91-9829132777