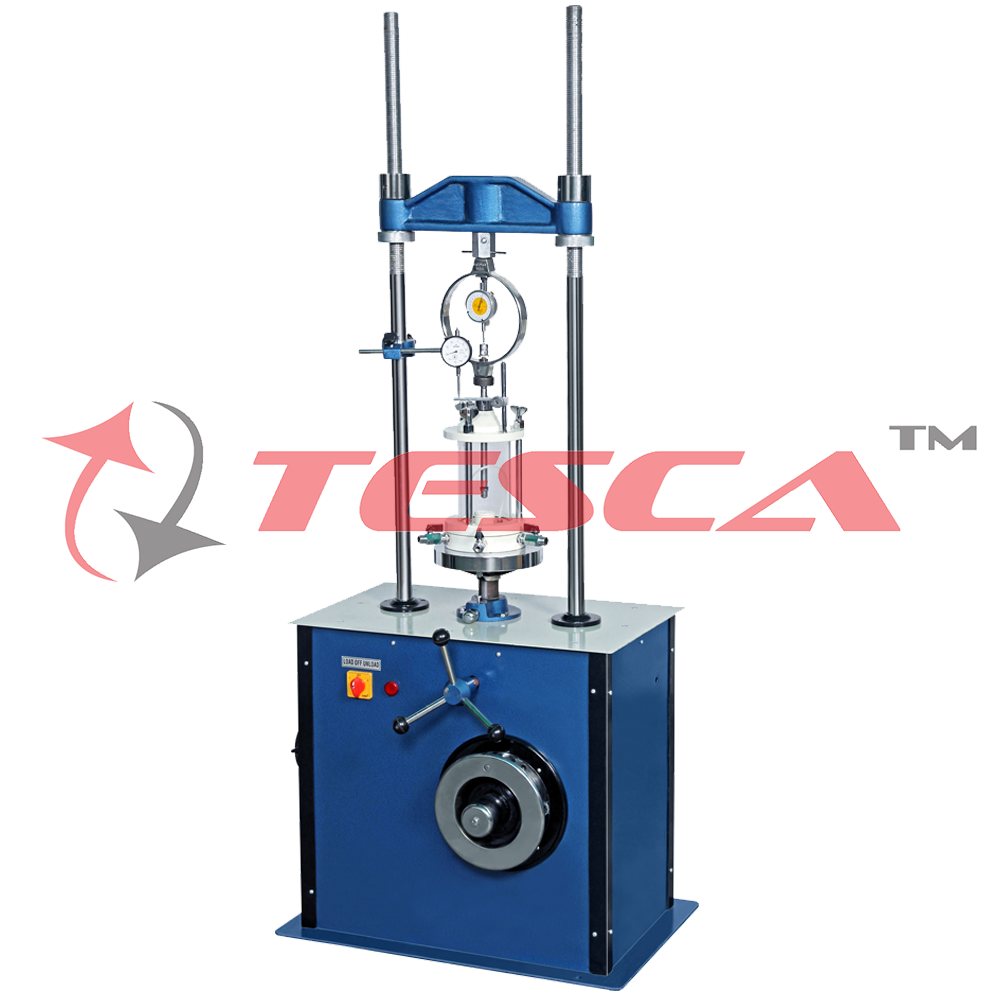

Triaxial Shear Test Apparatus - for 38mm Dia Specimen - with Accessories For UU Test, As Per (IS:2720) (Part Xi)

Order Code: MT253

Category: Soil Testing

Details The complete set up for the Triaxial test essentially consist of the following. Triaxial Cell - for 38mm dia soil specimen Loading Frame - 50 KN with 6 different speeds Proving Ring 200 kgf (2 KN) capacity with dial gauge 0.002mm ...

SPECIFICATION

Details

- The complete set up for the Triaxial test essentially consist of the following.

- Triaxial Cell - for 38mm dia soil specimen

- Loading Frame - 50 KN with 6 different speeds

- Proving Ring 200 kgf (2 KN) capacity with dial gauge 0.002mm x 5mm with calibration chart

- Dial Gauge 0.01mm x 25mm travel

- Lateral Pressure assembly

- The detailed description of all above accessories are narrated below.

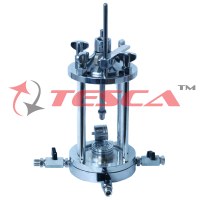

Triaxial cell

- FOR 38MM DIA SOIL SPECIMEN IS : 2720 (PART -XII) (Stationary Bushing) for 38mm dia specimens.:

- Consist of following parts and accessories

- Loading pad made of perspex for 38mm dia specimens

- Pair of plain discs made of perspex of 38mm dia x 6mm thick

- Pair of porous stone 38mm dia x 6mm thick

- Spilt sand former for 38mm dia specimen

- Sheath stretcher for 38mm dia specimen

- One dozen rubber sheaths for 38mm dia samples.

- For synthetic rubber, 'O' rings for 38mm dia specimen.

- One Plastic drainage tube

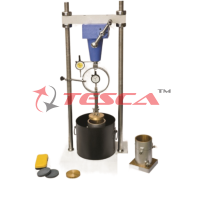

load frame

- Load Frames is useful device for application of Triaxial Shear test, The load application is effected by advancement of a lead screw secured against rotation by a sliding key. The load is measured with a proving ring.

- Two pillar type

- Enclosed motor and Gear system

- Jewel lamps indicating direction of motion

- Speed chart

- Operational ease

- Useful for Triaxial

Overall Dimensions : 450 X 700 X 1720 (L X W X D) mm

Net weight (in kg) : 167 kg

It consists of a cabinet which houses the electrical motor, reduction gear and the turret gear box. The loading is done by the upward movement of the lower platen which is firmly fixed to the lead screw. When the level is set in the neutral position, it isolates the lead screw from the rest of the drive mechanism, and the lead screw can then be manually moved up or down by operating the handle. On the unit, a main switch, a jewel lamp and a forward reverse switch are fixed. A relay is fitted inside the cabinet so that in case of power failure, the unit will not restart of its own on resumption of power, unless the switches are operated.

The adjustable cross head can be set at any required height over the two pillars and secured in position by tightening the adjustment nuts. It carries a hexagonal proving ring adaptor. A bracket for strain dial gauge is attached to one of the pillars of the load frame. Rates of strain are 1.25, 0.25, 0.05, 0.01, 0.002, 0.0004 mm/min. Suitable for operation on 230V, 50 Hz, single phase, AC Supply.

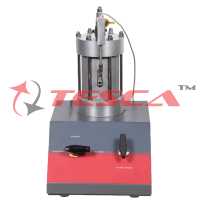

Lateral pressure assembly

The apparatus consists of a pressure chamber which has a flanged top cap fitted with a 10 Kg/Cm2 Pressure gauge and a valve for pumping in air. Water inlet and drain cock are fitted to the chamber. The foot pump supplied easily develops a pressure of 10 Kg/Cm2. Complete with connecting pressure hose.

91-9829132777

91-9829132777