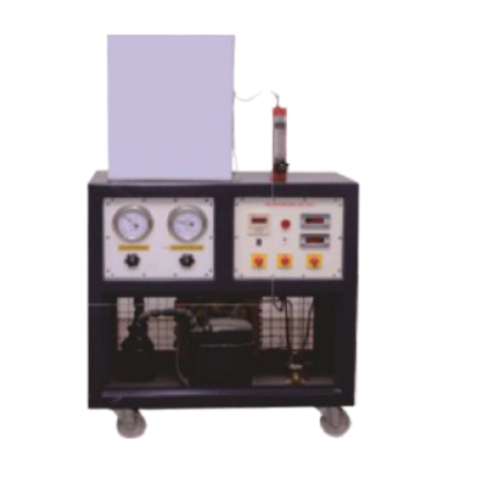

Vapour Compression Refrigeration Test Rig

Order Code: 21224924.3.1

Category: General Lab Equipment II

Scope (minimum) It should be a self-contained computer-controlled vapour-compression refrigeration system with automatic recording of all-important process variables using an integral USB interface device Compressor speed and power supp...

SPECIFICATION

Scope (minimum)

- It should be a self-contained computer-controlled vapour-compression refrigeration system with automatic recording of all-important process variables using an integral USB interface device

- Compressor speed and power supplied should be displayed on the PC. The hermetically sealed refrigerant exiting the compressor should pass through a condenser, receiver, filter, variable area flow meter, expansion valve and evaporator before returning to the inlet side of the compressor.

- Overall performance of the system is calculated and displayed continuously enabling the effect of changes in the system to be evaluated

- Submersible variable speed pumps supply water at a stable temperature and pressure from the reservoir to the condenser and evaporator eliminating fluctuations

- Condenser and evaporator both use plate heat exchangers enabling a full energy balance to be carried out while varying the operating conditions on both sides of the compressor

- Real-time superheat conditions in the condenser and evaporator should be calculated and displayed

- Real-time display for Coefficient of Performance (COP)

- Provision to change expansion valve setting by the operator to change the operating point (evaporator superheat setting)

- A refrigerant flowmeter as a sight glass enables observation of any vapour bubbles downstream of the compressor when conditions are not optimal • Alarm system to protect the equipment from misuse by switching the compressor off if pressures, temperatures, flowrates or pumps drift outside acceptable limits. Advanced warnings for operator to take remedial action before the compressor is switched off • Bourdon type gauges indicate the pressure and corresponding refrigerant saturation temperature on both sides of the compressor independent from the electronic systems.

- Provision to future expansion and integration

Experimental capabilities:

Ability to changing the operation of different parts of the process and recording the response of the complete system

- To operate vapour-compression refrigeration system and understand the relation between the hardware components and the refrigeration cycle

- First Law of Thermodynamics - The law of conservation of energy

- To investigate the effect on the refrigeration system of the flow of water through the condenser and to determine the optimum flow rate for a given load

- To investigate the effect on the refrigeration system of the flow of water through the evaporator and to determine the optimum flow rate for a given system load

- To investigate the effect of the flow of refrigerant through the refrigeration system, and whether there is an optimum flow rate

- To investigate the effect of closing/opening the expansion valve on a refrigeration system, and todetermine the optimum setting for a particular application

- Coefficient of Performance (COP)

- Thermodynamic system modelling

- To perform appropriate energy balances and a detailed analysis of the performance of the refrigeration system Layout Frame

- Metalic frame and panels.

- The unit includes wheels to facilitate its mobility.

Dimensions Layout

- Refrigeration unit:

- Length: 1.00m (Maximum)

- Width: 0.60m (Maximum)

- Height: 0.50m (Maximum)

- Water reserve:

- Length:1.00m (Maximum)

- Width: 0.80m (Maximum)

- Height: 0.78m (Maximum)

Technical specifications:

- Refrigerant: R-134a

- Hermetically sealed compressor: 2000 to 4500 RPM

- Hermetically sealed compressor supply: 24V DC to speed controller of brushless 3 phase DC motor

- Water cooled condenser through Plate heat exchanger

- Water cooled evaporator via Plate Heat Exchanger with submersible pump

- Variation of flow through plate Heat Exchanger

- Thermostatic Expansion valve: Danfoss TN2 Internally equalised valve

- Refrigerant flow measurement: Rotameter, Range: 10-35 Litres/min calibrated for 134-A

- Bourdon Pressure Gauge: 0-25Bar

- Bourdon Compound Gauge 0-10Bar

- HP/LP CUTOUT: Low Pressure 2 Bar/ High Pressure 16 Bar

- 24V DC Speed controller on compressor with integral power measurement on PC

- Electrically isolated

- USB computer connectivity

Temperature Sensors

- 9 x Thermistors to measure -25 to 100°C at

- Water in evaporator tank

- Water entering condenser

- Evaporator outlet

- Compressor inlet

- Condenser outlet

Ter in evaporator tank

- Water entering evaporator.

- Continuous indicator for evaporator superheat.

- Continuous indicator for condenser super cooling

Components:

- Vapor compression refrigeration test rig

- Control Interface Box

- Data Acquisition Board:

- Data Management Software

- Cables and Accessories

- Required Services, Assembly and Installation, Interface and Control Software, Starting-up, Safety, Maintenance, Calibration & Practices Manuals.

- A Compatible computer (PC) should be supplied

- Processor: 7th Gen. Intel Core i5 -7400 (6MB Cache) 3.0 GHz or higher

- 16GB DDR4 RAM or higher

- 1TB 5400 RPM SATA SSD or higher

- OS: Windows 10 (64bit) is recommended

- Keyboard /Mouse

Ports (recommended specs)

- 4 x USB 3.0

- HDMI-out

- DisplayPort 1.2

- 2 x Thunderbolt 3 (supports Type-C, USB3.1, DisplayPort, PS)

- Ethernet, audio out

- Computer Display: 21.5” LED monitor is recommended

91-9829132777

91-9829132777