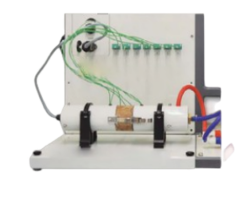

Whole sole flexing machine

Order Code: 23246708.1.2

Category: General Lab Equipment II

Bending angle: 90 degrees, Bending speed: 125-150/min (Speed adjustable), Diameter of mandrel: 30mm, Width of clamp: 144mm, Counter: LCD 0-999999, Contemporary test: 3 Samples, Sole Flexibility Tester: 0-50N, Dimensions (L X W x H) cm: (105x53x30

SPECIFICATION

Specifications:

A whole sole flexing machine is designed to determine the resistance of materials to cut growth during repeated flexing. It is especially applicable to outsoles of footwear including sole constructions. The machine has three workstations presented horizontally for operator ease. Loading, unloading and measurements are also much easier to carry out with the workstations presented in this manner. Samples are set at 140 flexes per minute and the number is recorded on a counter which has the facility to pre-set the number of flexes required. A jig is available and is used to locate the chisel and support the test while the initial chisel cuts are made. All moving parts requiring access are protected by a fully interlocked safety guard, ensuring the machine conforms to the latest safety regulations. A manual device to measure the stiffness of outsole may be required to see if the outsole must be flexed in accordance with international standards.

- Bending angle: 90 degrees,

- Bending speed: 125-150/min (Speed adjustable),

- Diameter of mandrel: 30mm,

- Width of clamp: 144mm,

- Counter: LCD 0-999999,

- Contemporary test: 3 Samples,

- Sole Flexibility Tester: 0-50N,

- Dimensions (L X W x H) cm: (105x53x30) cm,

- Weight: 100kgs.

General requirement: To determine the flex resistance of outsole, in according to international standards. The instrument clamp has 3 test places, angle of flex 90, flexing mode vertical type, electronically controlled with at least the number of cycles, adjustable speed of the movement, supplement for the proper and easy attachment of the specimens in the specimen holders.

91-9829132777

91-9829132777