Advanced Refrigeration Trainer

Order Code: 32402

Category: Refrigeration & Air Conditioning Lab

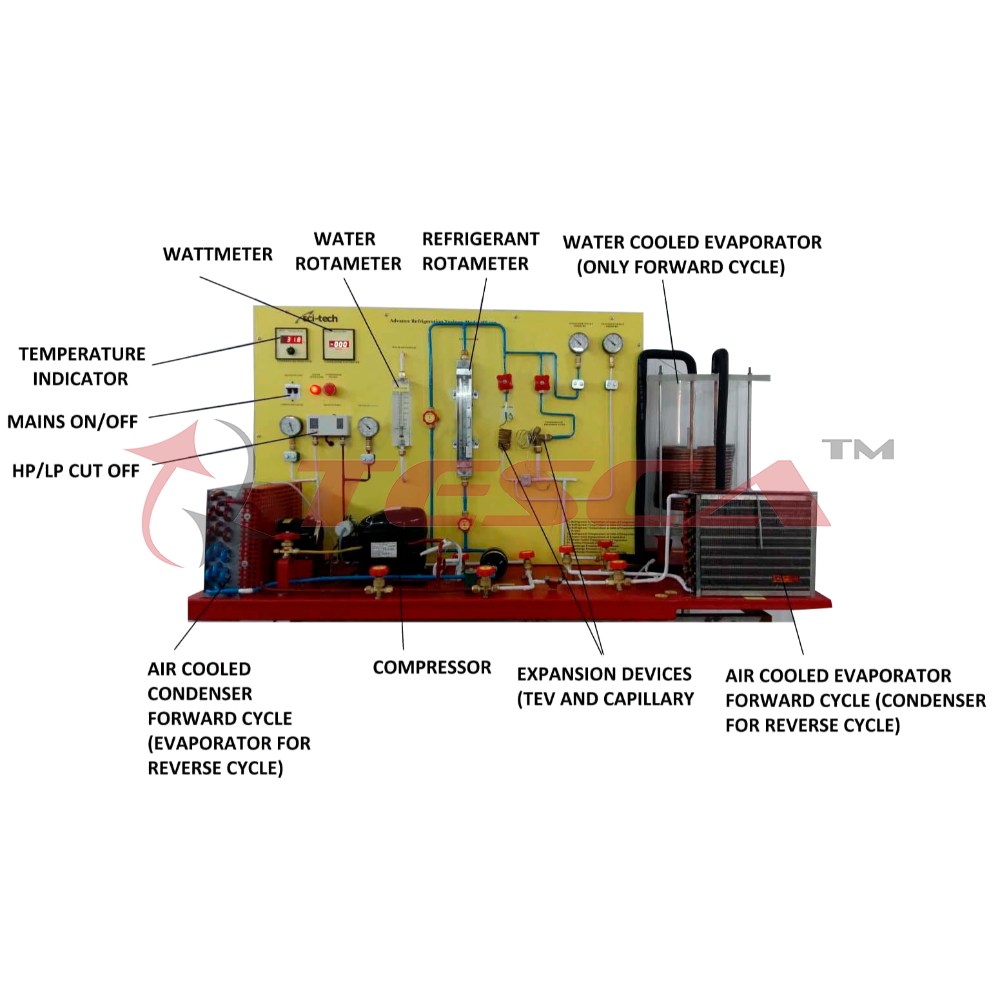

Tesca Advanced Refrigeration Trainer 32402 is designed to provide students with a thorough understanding of various types of systems used in commercial and industrial applications. It permits students to understand the refrigeration cycle, including ...

SPECIFICATION

Tesca Advanced Refrigeration Trainer 32402 is designed to provide students with a thorough understanding of various types of systems used in commercial and industrial applications. It permits students to understand the refrigeration cycle, including measurement of pressure, vacuum, flow rate and temperature.

The unit contains a reversing valve so that the system may be run as a heat pump in addition to operate as a refrigeration system.

Sight glasses at inlet and outlet of evaporator and condenser allows students to monitor changes in refrigerant state.

The system components are panel mounted to provide easy access for testing and troubleshooting. Incorporated two type of evaporator i.e. air cool type & water source type, it enables the study of compressor’s COP, through P - H Diagram Investigation & heat balance.

List of Experiments for Degree & Higher National Diploma Level

Familiarization with various types of compressor

Investigation on the operation of the compressor

Study of COP calculation in Refrigeration Cycle

Study of Pressure and Heat Analysis Diagram

Familiarization with the operating of metering devices, for instance, thermostatic expansion valve, manual throttle valve, capillary tube

Study on system control devices such as temperature controllers, thermostatic controls, solenoid valve Reverse Valve Heat Pump controls and backpressure regulator

Study on the principles of evaporator and condenser superheating and sub cooling, heat exchanger

Investigation of refrigeration system

List of Experiments

- Basic skill training

- Basic function of refrigeration control components, such operating principles and common fault & trouble shooting method

- Learn the sizing of condenser, evaporator and compressor units

- Troubleshooting of refrigeration cycle failure symptom and caused

- Basic electric control circuit and system of common air conditioning system

- System Setup: initial leak detection, leak detection, evacuating a refrigerant

- Study on receiver liquid receiver and suction line accumulator

- Familiarization with various types of compressor

- Investigation on the operation of the compressor

Technical Specifications

Compressor

- Hermetic : 450 Watt

- Refrigerant : R-134A

- Voltage : 240

Condenser

- Forced air coil with variable speed fan

Control devices

- Capillary tube

- Thermometer

- Solenoid valves

- Thermostatic controller

- Flow Meter

- Wattmeter, Voltmeter, Ammeter

Safety features

- Safety pressure switch

- Main breaker switch

- Compressor breaker switch

Evaporator

- Air Cooled Type

- Water Source Type

Option: Computer Controller System:

- Designed For Computer Control Plus Data Acquistion. Touch Screen Panel

- 13” Touch Screen Panel integrated into trainer

- Integrated processor computer

- HDMI output

- Board with data acquisition and control.

- Individual board for each sensor for signal processing.

- Power supply included.

- Different type of connectors for each sensor for avoiding connections mistakes between unit and interface.

- Single cable for connecting interface and computer, for avoiding dangerous and mistakes.

Scope of Delivery

Operating instructions, Student experiment book, Teacher's answer book.

91-9829132777

91-9829132777