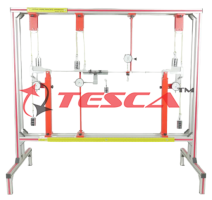

Bench Top Impact Test Machine Model

Order Code: 32221

Category: Strength of Materials Lab

Features Small-scale, convenient bench-mounting impact tester Ideal introduction to commonly used material impact testing techniques Many safety features including enclosure of all moving parts and mechanically interlocked guar...

SPECIFICATION

Features

- Small-scale, convenient bench-mounting impact tester

- Ideal introduction to commonly used material impact testing techniques

- Many safety features including enclosure of all moving parts and mechanically interlocked guard

- Allows investigations into the resistance of materials to crack propagation

- Includes digital display of energy absorbed at impact, and angular position before and after impact

- Visually effective, interesting and motivating experiments

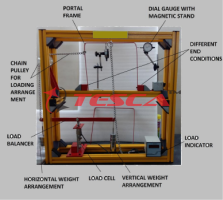

Tesca Bench Top Impact Test Machine is a bench-mounting, notched-bar impact tester. The equipment provides an effective, convenient and safe introduction to the principles of common impact testing techniques, enabling investigations into the resistance of materials to crack propagation. The apparatus consists of a main unit, an instrumentation unit and a power supply. The main unit consists of a pendulum supported in a rigid frame by low-friction bearings. The pivot arrangement includes an angular encoder to measure the angular position of the pendulum over its range of movement. The apparatus is fully enclosed with an interlocked guard covering all moving parts. Adjustable feet on the base of the unit enable accurate leveling of the equipment.

To perform a test, students raise the pendulum to the start position, where it is held by an electromagnet. They then clamp a specimen in a holder, which safely slots into the base of the frame at the lowest point of the pendulum swing. The separate instrumentation unit controls the release of the pendulum and measures and displays its angular position before and after the impact. The unit also directly displays energy absorbed by the impact in Joules.

The equipment is designed to fracture plain carbon steel, brass, copper or aluminum specimens. Lengths of each of these materials are included, along with a hacksaw and cutting jig to enable cost effective and convenient manufacture of test specimens. The cutting jig ensures repeatability of the notch position in each specimen and therefore valid comparisons of test results.

The equipment is supplied with a comprehensive user guide which includes equipment description and technical specification, installation and assembly, background theory, experiment procedures with results, and maintenance instructions.

Specifications

Specimens:

Cut from 3.2 mm diameter rod, supplied as:

- 2 m aluminum alloy

- 2 m copper

- 2 m brass

- 2 m mild steel

Accessories (included):

- Hacksaw and 10 hacksaw blades

- Cutting jig

- Two specimen holders

- Allen keys

Experiments

- Introduction to the principles of common impact testing methods, such as Izod and Charpy tests

- Investigations into the resistance of materials to crack propagation

91-9829132777

91-9829132777