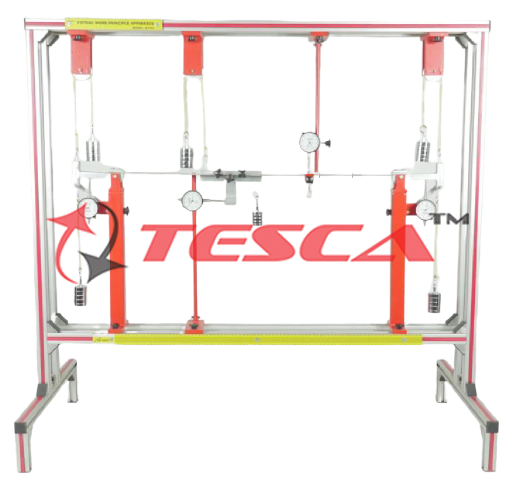

Virtual Work Principle Apparatus

Order Code: 32223

Category: Strength of Materials Lab

Features comparison of different methods to determine the elastic line: virtual work, Mohr’s analogy statically determinate and indeterminate systems various load cases: point load or bending moment Beams are key struc...

SPECIFICATION

Features

comparison of different methods to determine the elastic line: virtual work, Mohr’s analogy

statically determinate and indeterminate systems

various load cases: point load or bending moment

Beams are key structural elements in mechanical engineering and in construction which are subject to deformation under load. In the case of a simple beam this deformation can be predicted by various methods, such as the principle of virtual work.

The beam under investigation in 32223 can be supported by different bearing methods. Two supports with clamp fixings and an articulated supports with a force gauge are provided to realise statically determinate or indeterminate systems. The two supports with clamp fixings are provided with dial gauges and can also be used as articulated supports. These dial gauges enable the angle of inclination of the beam to be determined at the support. A third dial gauge records the deflection of the beam at a random point.

A device is additionally provided to generate a bending moment at a random point on the beam. A fourth dial gauge records the angle of inclination of the device.

The beam is placed under load by weights (point load and coupled forces to generate the bending moment). The clamping moment on the supports can be determined by means of weights. The various elements of the experiment are clearly laid-out and housed securely in a storage system. The complete experimental setup is arranged in the frame 32150.

Tesca Virtual Work Principle Apparatus is used for applying the principle of virtual work to the derivation of redundant reactions. It is to be used with Universal Structural Frame. An elastic beam is supported at both ends by moment supports. Both supports permit the application and measurement of moments and rotations. A third support, vertical force support, is used for the case of two span continuous beam. A clamp on moment application device with a mean to counter balance the device weight is provided to apply a pure moment and measure rotation. The beam is loaded by weights. The deflection and slope of the beam can be measured by dial indicators.

Specifications

Comparison of different methods to determine the elastic line

Statically determinate or indeterminate beam

2 supports with clamp fixing, optionally as articulated support with measurement of angle of inclination or clamp fixing

1 articulated support with force gauge

Device to generate a bending moment

dial gauge with generation of moment to measure the angle of inclination

Dial gauge to record the deformations of the beam

weights to subject the beam to point loads or moment

Weights to determine the clamping moments on the supports with clamp fixings

Storage system to house the components

Experimental setup in frame SE 112

Technical Specifications

Beam

? Length: 1000mm

? Cross-section: 20x4mm

? Material: steel

Weights

? 7x 1N (hanger)

? 28x 1N

? 21x 5N

Measuring ranges

? Force: ±50N, graduation: 1N

? Travel: 0…20mm, graduation: 0,01mm

Experiments

- Elastic lines for statically determinate or indeterminate beams under load

- Determination of the elastic line of a beam by

- The principle of virtual work (calculation)

- Mohr’s analogy (area moment method devised by Mohr; graphical representation)

- Application of the principle of superposition

- Determination of the

- Maximum deflection of the beam

- Angle of inclination of the beam

- Comparison between calculated and measured values for angle of inclination and deflection

91-9829132777

91-9829132777