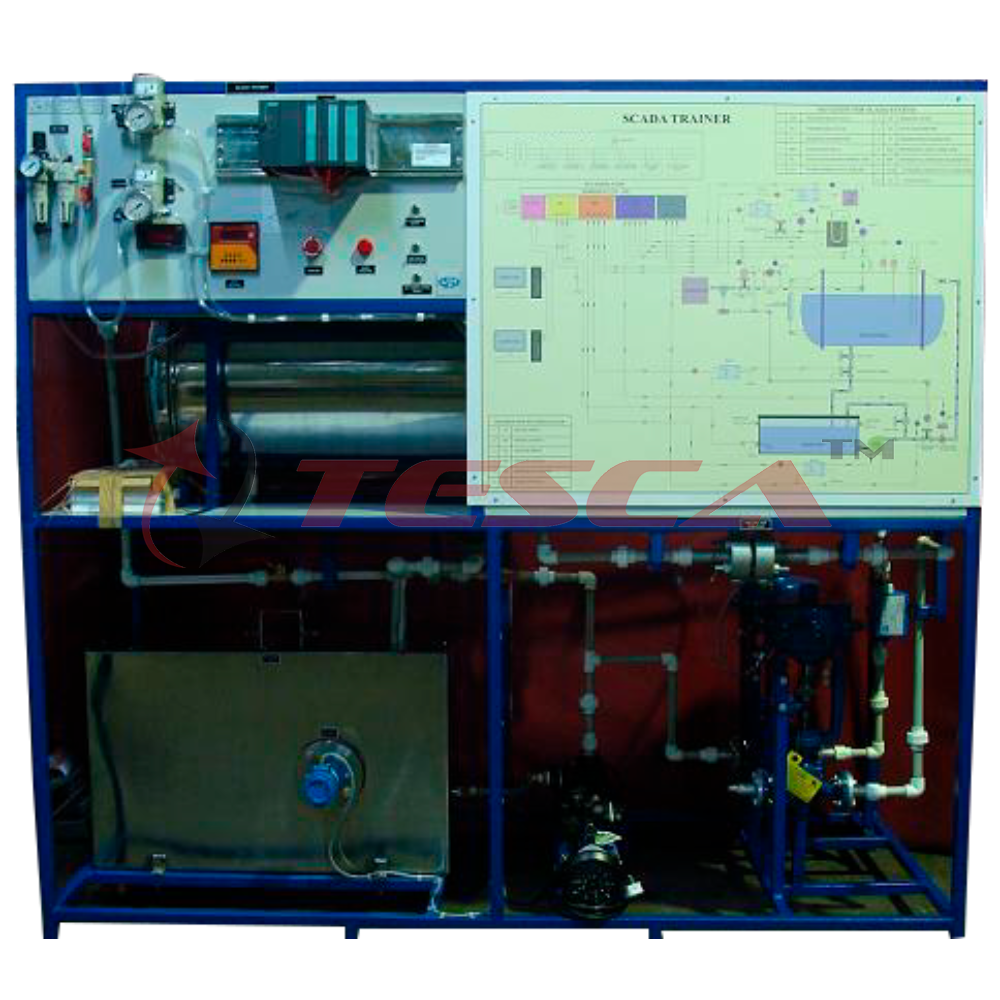

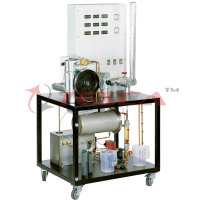

Boiler Drum Simulation Trainer

Order Code: 32452

Category: Boiler & Steam Generators

Tesca has design the system in such a fashion that easily operated demonstrated & requisite experimentation can be performed. Sci-tech provides a comprehensive unit; The Boiler Drum Simulation Trainer is able to exhibit realistic response times, uses

SPECIFICATION

Description

Tesca has design the system in such a fashion that easily operated demonstrated & requisite experimentation can be performed. Sci-tech provides a comprehensive unit; The Boiler Drum Simulation Trainer is able to exhibit realistic response times, uses standard industrial process instruments and process equipment’s and designed to study the response of type ‘0’, ‘1’, and ‘2’ control system. It is a P.C. based system with visual display of the process on the monitor screen. The software used in this system is a window based software and is completely menu driven for experimentation. Visual display of MIMIC is provided with this system and graphics is viewed on monitor screen. Printing of data in tabular and graphical form is provided.

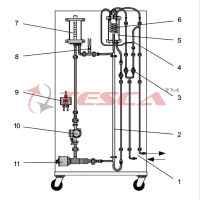

The system able to perform Level Studies and Shell and Tube heat Exchanger Studies function. In Level Studies the level transmitter is capable of measuring drum level in open or close tank application using the differential pressure method or other suitable method

A heater is provided to heat up water in the drum and act as energy input to the boiler.

Level switch installed in the boiler drum to cut off the electric heater if drum level is low-pressure transmitter must be provided to measure the pressure. In Shell and Tube heat Exchanger Studies consists of two main circuit: Hot water Circuit and Cold water Circuit

Features

- Compact, comprehensive sturdy design

- Full instrumentation for experimentation on boiler control system.

- A pilot plant of boiler

- High - speed dynamic signal acquisition is possible.

- Menu driven screens with comprehensive HELP menu

- Displays graphically both on-line and historical trends

- PC based system.

- System having all process indication in color mimics.

- System is able to exhibit realistic response times, use standard industrial process instruments and process equipments

- System having facility of on line measurements for boiler drum level, feed water in flow, hot water outflow, drum pressure hot and cold water circuit temperature for heat exchanger and other instrumentations.

- Temperature, level and pressure indicator are provided for indication.

- Rota-meter is provided to measure flow rate.

- Air release valve is provided to release excess pressure to atmosphere, in case for over-pressure in the boiler drum for safety purpose

- Pressure and temperature gauges are provided.

- Provided with Alarm Annunciation

- Provided with Fault Stimulation Switches

- Powder coated structured is provided.

Computer Console

A mild steel panel that mounts the computer, the signal conditioning unit, the interfacing and communication systems along with all necessary power supplies.

Software

Extremely user friendly and menu-driven system, the software draws performance results from acquired data and presents them graphically. A hard copy can be obtained on a printer.

Spare channels on the interfacing unit are provided for further experimentation and research.

The software will allow the teacher to get continuous update on the progress of the student.

The facility will be provided to keep the record of such program.

System Specifications

The System /Trainer is operated manually and also using software control interface with computer, Software facilitates the data logging, processing and displaying data graphically which includes data processor and storage unit compatible with the teaching unit .Also System having following component.

Drum Level Controller

- Type: Microprocessor based or equivalent.

- Input : 4 to 20mA

- Outputs: 4to 20mA

- Controls: PID And Self-Tuning

Product temperature controller

- Type: microprocessor based or equivalent.

- Input :4 to 20mA

- Controls : PID and Self-Tuning

ON/OFF Controller

- Type: microprocessor based or equivalent.

- Inputs : 4 to 20mA

- Controls : On/Off

Batch Controller

- Type: Microprocessor based or equivalent.

- Inputs : 4 to 20mA

- Controls: On/Off

Chart Recorder

- Type : Continuous Pen

- No of Pen : 4

- Chart: Z-fold

- Chart speed : 3600mm/hr, stepped

Level Control Valve

- Type : Globe

- Actuator : Diaphragm

- Size : I”

- Range :0-100%

Temperature

- Type : Globe

- Actuator : diaphragm

- Size : I”

- Range : 0-100%

I/P Converter/Positioner

- Input : 4 to 20mA

- Output : 3 to 15 PSI

Pressure Transmitter

- Range : 0to 30psig

- Output : 4 to 20mA

Level Transmitter

- Range: 0 to 1000mm

- Output : 4to 20 mA

Orifice D/P Transmitter

- Range : 0to 60 LPM

- Output: 4 to 20mA

RTD Temperature Transmitter

- Range:0to 1000 C

- Output: 4 to 20mA

T/C Temperature Transmitter

- Range: 0 to 1000 C

- Output : 4 to 20mA

Hand Valve:

- Type : ball/globe

- Material : Brass/ Stainless Steel

Process Tank(approx.)

- Pre-heater : 120L

- Product : 120L

- Cold Water : 120L

- Boiler Drum :140L

Relief Valve

- Type : Spring Loaded

- Material: Brass/Bronze

Process pump(approx.)

- Feedwater : 60LPM

- Steam circulation : 60LPM

- Product Circulation : 40 LPM

- Product Cooling : 40 LPM

Vortex Flowmeter

- Range : 0 to 60 LPM

- Output : 4 to 20mA

Shell and Tube Exchanger:

- Shell:1

- Tube:2

- Heat transfer area : 1.5m2

- Duty : 25kW

Pressure Gauge

- Type : Bourdon Tube

- Dial Size : 100 mm

- Range: 0 to 100 psig and 0 to 60 psig

Temperature Gauge

- Type : Bimetallic

- Size : 100mm and 75mm

- Range : 0 to 1200 C and 0 to 1000 C

- Material : Stainless Steel

Alarm Annuciator of Points : 4

Fault Stimulation Switch of points: 5

Thermoanemometer and humidity meter

- Air velocity : 04 to 25m/s

- Temperature : 500 C

- Humidity : up to 95 % RH

Tachometer

- Speed range : 6-99,000rpm

- Resolution:0.1rpm

- Accuracy : ±0.4%± I digit

Personal Computer -

- CPU : AMD Phenom II X6 945 Processor or better(3.0 GHz, 8M Total Cache)

- Motherboard:Min.1333 MHz bus speed range

- Bus Architecture : 1333Mhz FSB of Better, Min 1 PCI2.1 Compliant slot free, Min 1 PCI Express2.0

- Main Memory : Min 4 GB (2×2GB) DDR3 1333MHz Memory

- Video: Min 512MB Direct X10 Capable of must be compatible with the software

- Display Monitor: Min21” LCD TFT Flat Panel, Min Resolution 1280×1024.

- Hard disk Drive : Min 500 GB (SATA 2)at 7200rpm.Min 8 MB Buffer Cache Size

- Network card: Support 10/100/1000Mbps

- IDE Ports : Min 2 Serial ATA 3GB/sports

- Input/Output ports: Min8×USB 2.0 Ports(Min2front),I x serial port 1 × PS/2 keyboard port, 1×DB-15VGA Video Port & I ×DVI Video Port

- Software: Pre-Install with Windows 7 Enterprises UNIMAS license with recovery dvd.

- System Casting : Tower casing, must be lockable casing

- Standard equipment : 1 × 104 key keyboard(USB), I × optical scroll mouse (USB)

- Sound card: Sound blaster compatible

- Sound system : with speaker

- DVD ROM: Min 16 x DVD-RW drive

- Utility Software: Preferable comes with Comprehensive Protection & Data Security, System Back Up and Recovery Software, Bios configuration software (support Microsoft window XP/Vista).Diagnostics & Management software.

- voltage stabilizer, Uninterrupted power supply, lightning Protection System compatible with teaching unit.

Operation & Maintenance Manual

Self-explanatory operating & maintenance manual will be provided. This will include Theory, operating procedure, standard results, and maintenance procedures.

Service Required at Site

- Electric Supply three phase/single phase with proper earthing.

- Proper water supply.

91-9829132777

91-9829132777