Centrifugal Governor Apparatus

Order Code: 32163

Category: Strength of Materials Lab

Features Visualization of the effect of centrifugal force1 How various centrifugal systems work1 Determination of characteristic curves and setting curves of different centrifugal governors Centrifugal governors use the properties of centrifugal ...

SPECIFICATION

Features

Visualization of the effect of centrifugal force1

How various centrifugal systems work1

Determination of characteristic curves and setting curves of different centrifugal governors

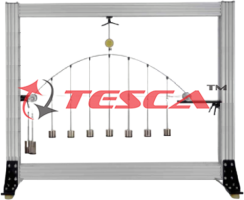

Centrifugal governors use the properties of centrifugal force to regulate the speed of a machine. Due to centrifugal force, a rotating flyweight mass has the tendency to move away from the axis of rotation and is prevented by counteracting mechanisms. These mechanisms are differentiated into those governors that use weights and those that use springs. Corresponding kinematics cause a deflection proportional to the rotational speed to occur on the governor. Via an actuator, this affects the energy supplied to the machine, thereby regulating the machine's speed. Tesca Centrifugal Governor Apparatus experimental unit presents centrifugal systems that demonstrate the different principles of operation of both weight and spring-based governors.

The housing holds the drive with electronically controlled motor. The speed is infinitely variable with a 10-turn potentiometer and displayed digitally. The governors are inserted into a chuck on the drive. Centrifugal masses, sleeve forces and spring preload can be varied using the accessories supplied, depending on the governor. The stroke can be read on markings on the governor shaft. A transparent protective cover above the rotating centrifugal governor ensures safety: operation is only possible when the protective cover is properly attached. The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specifications

How centrifugal systems work

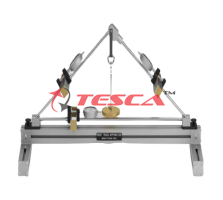

Three different centrifugal governors: Porter, Proell and Hartnell governors

Versatile range of variations on the governors: adjustment of the centrifugal mass, the sleeve force and the spring preload

Stepless adjustment of speed via a potentiometer

Drive with DC motor

Digital speed indicator

Protective cover with electronic coupling to the drive ensures safe operation

Technical Specifications

DC motor:

Max. power 35W

Max. speed 6000min-1

Speed regulation 60...400min-1

Proell governor:

Sleeve mass 3x 100g

Centrifugal mass 2x 150g

Porter governor:

Sleeve mass 3x 100g

Centrifugal mass 2x 400g

Hartnell governor:

Centrifugal mass 2x 400g

2 compression springs, adjustable spring preload

Measuring range

- Speed: 0...600min-1

Experiments

kinetics and kinematics of the following centrifugal systems

Porter governor

Proell governor

Hartnell governor

Adjustment of centrifugal governors

Recording the governor characteristic curves and setting curves

Calculation of the structural design and adjustment of different governors

Scope of Delivery

1 experimental unit

3 centrifugal governors

1 set of tools and weights

1 set of instructional materials

91-9829132777

91-9829132777