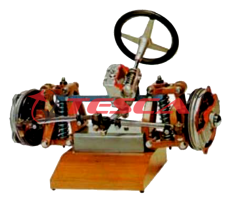

Electronic Power Steering Trainer

Order Code: 32711

Category: Steering Trainer

System Features Real-time automobile EPS system is used to illustrate the structure of the system. 3-phase motor drives a booster pump to operate the steering wheel and adjust the speed signal imitation knob. In this way, the device demonstra...

SPECIFICATION

System Features

- Real-time automobile EPS system is used to illustrate the structure of the system.

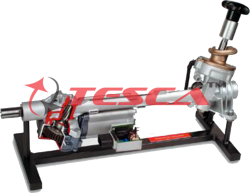

- 3-phase motor drives a booster pump to operate the steering wheel and adjust the speed signal imitation knob. In this way, the device demonstrates electric power steering.

- Construction incudes aluminum extrusion chassis which is corrosion resistance, impact resistance, fireproof, and moisture proof.

- The trainees can learn and analyze the working principle of the control system by referencing the diagram and the real automobile system.

- The training bench is installed with detection terminals to detect electric signals, for example, resistance, voltage, current, and frequency, of circuit components of the EPS.

- Self-retention wheels are installed to ensure that the platform is flexible, reliable and endurable.

- Optionally equipped with intelligent fault setting and appraisal system, include fault setting, troubleshooting and assessment functions etc.

System Description

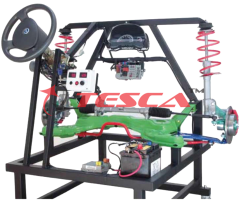

Electronic Power Steering Trainer Order Code : 32711 offers front axle assembly to holistically demonstrate structure and operation of the EPS system and front axle suspension system. The device applies to theoretical teaching and maintenance training of the EPS system in secondary and senior vocational skill schools, normal education and training institutions. TPS operating principle and function can be tested and diagnosed efficiently and systematically by controlling the power of tire and EPS operational simulating system.

Speed sensitive variable assist power steering system is operated with inverter and TPS, VSS variable controller. And power pump pressure, thermometer and TPS values are indicated with digital volt meter. The digital meter is attached to the speed-sensitive valve. By installation of diagnosis and fault control module and diagnosis terminal to ECU and circuit, input and output condition can be controlled. Input and output data can be measured and trained conveniently with multi-meter, oscilloscope, diagnostic system etc.

EPS circuit diagram panel is elegant with a m printed membrane. By installing a power oil pressure gauge and thermometer, it is effective for test training. Control panel has an excellent durability with installation of main switch, power lamp, power connector, key switch, safety switch, TPS, VSS, variable controller, digital meter, inverter, cluster, DLC, DM to an aluminum plate. Frame is cross- sectioned to see the operation of power cylinder and color indication for each input, output, and control line of hydraulic system enhances the educational effect.

List of Experiments

- Understanding the operating principle and diagnostic test of electronic power steering system

System Components

- Driving power supply: three-phase four-wire (three-phase five-wire 380±10% V 50 Hz)

- Input power: A.C. 220V ± 10% 50 Hz

- Operating power supply: 12V DC

- Operating temperature: -40? to +50?

- Oil pressure gauge: 0 – 100 kg/psi

- Three-phase asynchronous motor

- Optionally equipped with intelligent fault setting and appraisal system, include fault setting, troubleshooting and assessment functions:

- Components: EPS, ECU, instrument, car speed sensor, solenoid valve, power pump, pressure pipe, control valve, chamber rack, booster cylinder, wheel, tire.

- The operating principle education of hydraulic circuit system installed to EPS power steering system and additional maintenance training can be done.

Service Required at Site

- Electric supply 230 V AC, 50 Hz & 440v for three phase supply.

91-9829132777

91-9829132777