HMP™_6A Range of Surge Reduction Check Valve

Order Code: HMP™_6A

Category: Range of Check Gate and Butterfly Valves

OVERVIEW The HMP™_6A Axial Range Surge Reduction Check Valve stops reverse flow. It is commonly used in pump stations to stop the pump from running in reverse when the pump is stopped. The HMP™_6A Axial Surge Reduction Check valves wer...

SPECIFICATION

OVERVIEW

The HMP™_6A Axial Range Surge Reduction Check Valve stops reverse flow. It is commonly used in pump stations to stop the pump from running in reverse when the pump is stopped. The HMP™_6A Axial Surge Reduction Check valves were designed to reduce the effects of water hammer when the check valve shuts down. Most conventional check valves on the market today only reduce flow in the last 30% of closure resulting in a rapid slamming action which creates water hammer.

The HMP™_6A Axial surge reduction check valves were developed to be more energy efficient with a better flow co-efficient (Cv) than most nozzle check valves on the market today. The nozzle check reduces the effects of water hammer but none of our competitors are energy efficient. In pumping systems, energy efficiency is crucial. Energy efficient valves will allow for a maximum amount of fluid to be pumped in the shortest amount of time that the pumping system can deliver. Whereas the time to pump the same amount of fluid with low energy efficiency valves will increase. Over time this will drastically increase the running cost of the pump station due to increased energy requirements as well as wear and tear on pumps and valves.

The HMP™_6A Axial surge reduction check valve has been developed to present a robust, simple and cost effective high pressure (up to 25 MPa / 3 626 Psi) solution to fluid handling issues in any industrial sector.

OPERATING CONDITIONS

These valves are designed to operate in systems with relatively clean media like water or other liquids with a low percentage of suspended solids and chlorides. The valve’s operating pH range is 2 – 14 pH.

SIMPLICITY

The HMP™_6A Axial surge reduction check valve, disc is shaped to allow for a smoother flow path around it. The disc is carried by a shaft that can slide in a guide on the outlet side of the HMP™_6A axial surge reduction valve body. On the outlet side of the surge reduction valve body guide, the guide is partly closed, creating a compartment. By closing the compartment partly, during a closing operation a vacuum is created inside the compartment of the guide. This prevents the disc from slamming shut and the HMP™_6A Axial surge reduction check valve therefore closes in a controlled manner which drastically reduces the occurrence of water hammer. By carrying the disc on a shaft, bush and guide, we increase the life of the HMP™_6A Axial surge reduction check valve when compared to conventional check valves. Conventional check valves all have a hinge systems attached to the door / disc. These hinge systems are not very reliable as the hinges wear out and prevent the door /disc form closing to the correct position causing the check valve to leak and fail. A spring is installed in the HMP™_6A Axial surge reduction check valve to keep it in the closed position for commissioning. After the system is charged with pressure, the pressure acts on the moving wetted parts and forces the HMP™_6A Axial surge reduction check valve closed and the spring serves no purpose. Once the pump starts or the pressure is higher from the inlet side of the HMP™_6A Axial surge reduction check valve, the higher pressure pushes the check valve disk open.

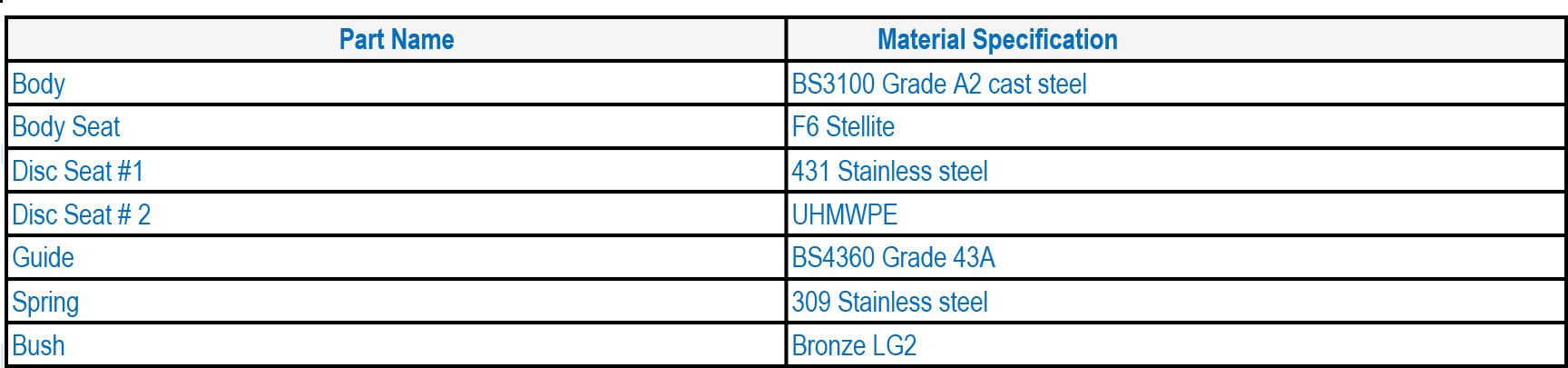

MATERIALS OF CONSTRUCTION

FEATURES

- HMP™_6A Axial Surge Reduction Check valve has a hard and soft seat. It can therefore withstand a little bit of dirt and is more reliable then conventional double and single door non return valves.

- It has no hinge mechanism, making it far more robust.

LOW MAINTENANCE REQUIREMENTS

The HMP™_6A Axial surge reduction check valve only has one moving part making it very reliable. It is manufactured from stainless steel which increases reliability and durability. The HMP™_6A Axial surge reduction check valve requires minimal maintenance which is made easy by removable guide configuration.

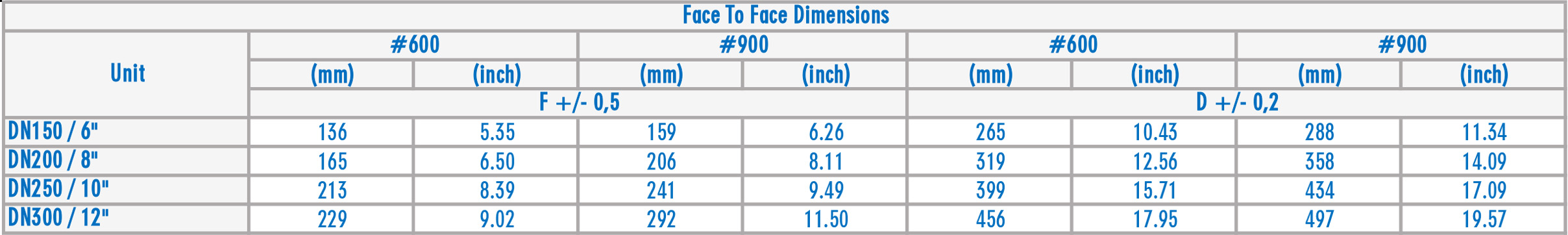

DIMENSIONS

DESIGN AND MANUFACTURING STANDARDS

The HMP ™_6A Axial Range has been designed in accordance with various international standards as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.3 ANSI B16.34

ANSI N278.1 ANSI B16.37

Available sizes: DN150 / 6" to DN300 / 12"

Pressure rating: up to 25MPa / 3 626 Psi

Can fit between ANSI B16.5 and BS4504 end connections.

91-9829132777

91-9829132777