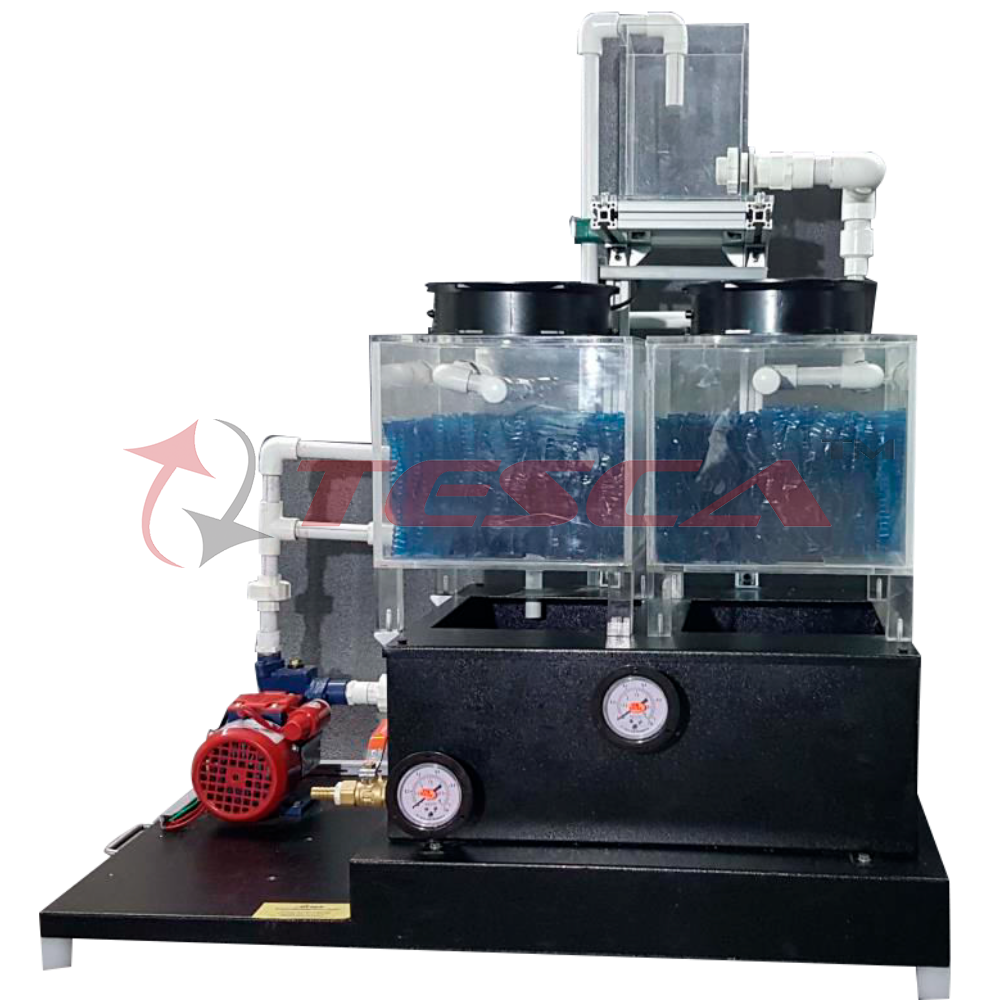

Induced Draft Cooling Tower Model

Order Code: 32441

Category: Refrigeration & Air Conditioning Lab

Induced draft cooling towers, are constructed such that the incoming circulating water is dispersed throughout the cooling tower via a spray header. The spray is directed down over baffles that are designed to maximize the contact between water and a...

SPECIFICATION

Induced draft cooling towers, are constructed such that the incoming circulating water is dispersed throughout the cooling tower via a spray header. The spray is directed down over baffles that are designed to maximize the contact between water and air. The air is drawn through the baffled area by large circulating fans and causes the evaporation and the cooling of the water.

Tesca Induced Draft Cooling Tower 32441 offers a scaled down version but actually working model of large scale induced draft cooling tower model with actual parts for offering the readings of such towers.

System Description

- Base Stand: This is an M.S. structure made of 25 X25 mm square pipe. The structure has outer dimension of 900 X 500 X 80(L X B X H).This structure is powder coated in black colour. Aluminum section of 30 X 30 mm also been used which supports the motors.

- Sump Tank: It is assembled on the base tank by nut bolting. This is also made of mild steel and powder coated in black colour. It has outer dimension of 550 X 420 X 200 (L X B X H) mm.

- Axial Fan: This is an axial fan mounted on the top of the cooling tower. It sucks the air toward it from the opening provided on the bottom of the cooling tower. It requires 220 volt alternate current supply and rotates anti clockwise sense when viewed from the above.

- Water recirculating Pump: This is a centrifugal pump having power of 0.125 Hp mounted on the base stand. It pumps the water from the sump tank to the overhead tank. The flow rate going to overhead tank can be controlled using flow control valve.

- Overhead Tank: It is an acrylic tank being held over the cooling tower. It is supported by aluminum section stand. It has outer dimension of 150 X 150 X 250 (L X B X H) mm. The tank supplies water to both the cooling towers.

- Control Panel: It is provided on the base stand which has mains on/off switch and indicator to start and stop the system. It is made of acrylic sheet of 5 mm thickness with a membrane pasted on it.

- Drain Valve: A brass forged ½ inch valve is provided on the left hand side of the sump tank for the purpose of draining out the water.

- Pressure Gauges: Two pressure gauges are tapped on the sumo tank. The lower one indicates pressure at the suction side whereas the upper one indicates the pressure on the discharge side. It has range of 1 Kg/cm2

91-9829132777

91-9829132777