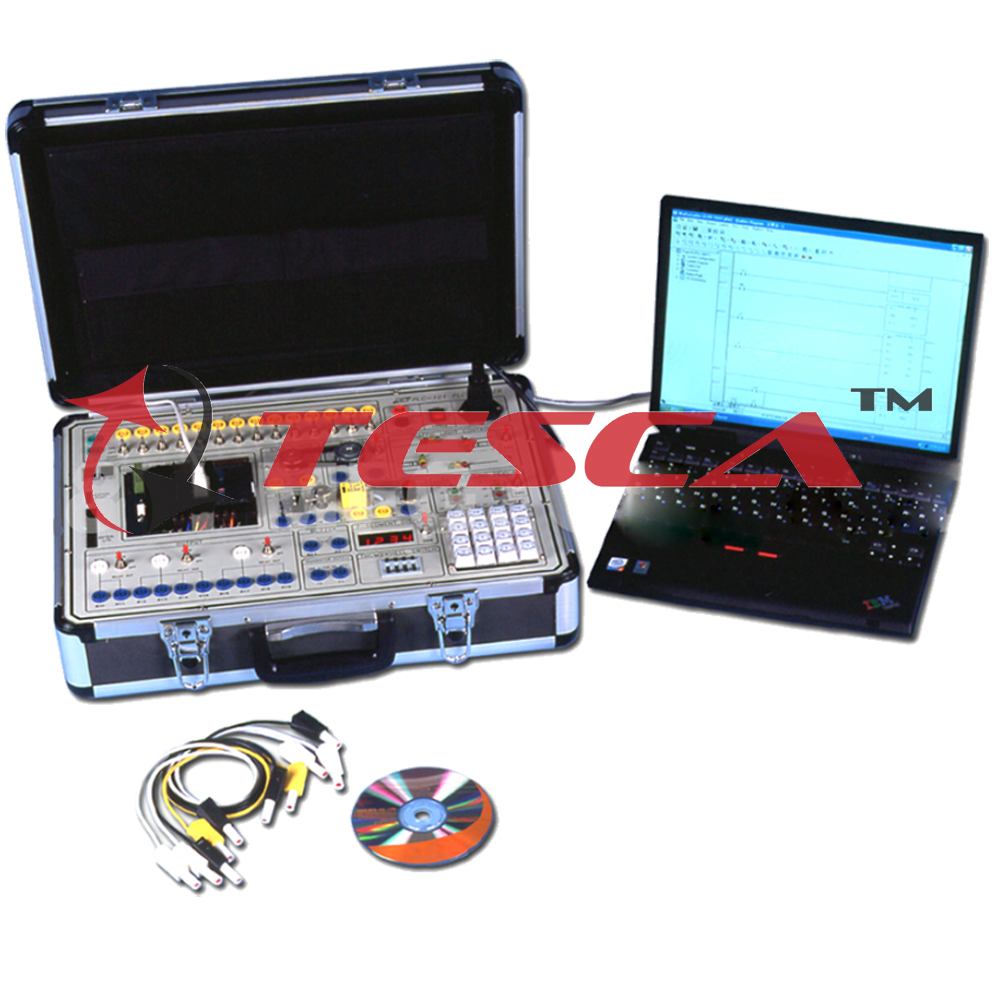

PLC (Fatek) Trainer 14 Input / 10 Output

Order Code: 52018A

Category: PLC Trainers

Since PLC (Programmable Logic Controller) was first introduced in 1970, it has been in common usage in various industries such as machine and process controls. Designed with the latest microprocessor and electronic circuitry, today’s compact PL...

SPECIFICATION

Since PLC (Programmable Logic Controller) was first introduced in 1970, it has been in common usage in various industries such as machine and process controls. Designed with the latest microprocessor and electronic circuitry, today’s compact PLCs features high reliability, high performance, high speed and networking. The use of PLCs in automated production lines enhances system reliability, product quality, information sharing, efficiency and flexibility and thus reduces costs.

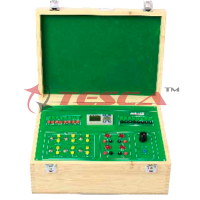

52018A is a self-contained trainer which consists of a FATEK PLC main unit and commonly used I/O devices for simulation. It provides students with a thorough understanding of the theories and applications of programmable logic controllers. The trainer enables students to learn step by step from the fundamentals of PLC to more advanced controls used in industry.

Features

- Input-simulation switches function as level and pulse input for different input signal

- Installation of output relay helps to increase load current

- Easy-to-use, windows-based development software

- With various peripheral devices and other devices that support external extensions, particularly suited for laboratory experiment and project implementation

- Equipped with various simulations I/O devices for the convenience of studying and observing the results

- Use 4mm safety sockets input/output terminals to ensure the physical safety of users

- Easy to carry, move and store with a suitcase design

Specifications

- AC power supply : 100V-240V AC, 50/60 Hz

- PLC main unit : FATEK FBs-24MC

- Digital input : 14

- Digital output : 10

- Support 16 high-speed counters

- Support five 0.1ms high-speed timers

- Execution speed (average) : 0.33µs/ sequential instruction

- Four Communication ports :

- USB, RS-232, RS-485, ethernet ; expandable up to 5 ports ; maximum transfer rate : 921.6K bps

- One 4-digit 7-segment display

- One 4-digit thumbwheel switch

- One step motor

- One encoder

- One 24V DC motor

- One proximity sensor

- One micro switch

- One buzzer

- One 4x4 keypad

- One 24V DC expansion power

- Provide module expansion port and DIO extension port

- Provide traffic light control module

- Provide tank-filling device module

- Windows-based programming software (Win Proladder) allows the programmer to modify the program while running

Experiments

1. Win Proladder operations

- Editing ladder program

- Testing ladder program

- Monitoring status

2. Basic control circuits

- Self-holding circuit

- Flashing control

- Inching control

- Single button control

3. Light control

- Simple light control

- Complex light control

4. Traffic light control

- Traffic light controller (step)

- Traffic light controller (conventional)

5. Digital clock control

- 7-segment display control

- Time clock

6. Step motor control

- Speed and direction control

- Encoder operation

- Step motor and encoder

- Step display of step motor

7. Tank filling device control

- Tank filling control

- Tank filling control with thumbwheel

8. Keypad control

- Keypad operation

- Digital lock control

9. DC motor control

- PWM speed controller

- Proximity and micro switches

- Automatic speed control

10. Multiple PLC trainers

- Connecting PLCs via RS-485

- Connecting PLCs via ethernet

System Requirements

- PC with Pentium II or better CPU

- Windows 98 / 2000 / XP

Accessories

- USB cable

- Connecting leads set

- Power cord

- Experiment manual

- User’s manual

91-9829132777

91-9829132777