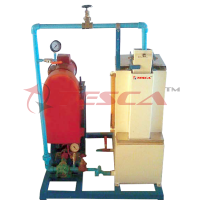

Plate & Frame Filter Press Apparatus

Order Code: 32123

Category: Fluid Mechanics Lab

Features: Separation of solids from suspensions with a plate and frame filter press Discontinuous cake filtration Practical experiments on a laboratory scale Plate and frame filter presses are used in the...

SPECIFICATION

Features:

- Separation of solids from suspensions with a plate and frame filter press

- Discontinuous cake filtration

- Practical experiments on a laboratory scale

Plate and frame filter presses are used in the beverage industry, for example, to clarify intermediate products.

A suspension of diatomite and water (recommended) is prepared in a tank. A pump ensures that the solid remains suspended and does not settle. The pump delivers the suspension into the individual separating chambers of the plate and frame filter press. A separating chamber is formed by one filter frame and two filter plates. The filter plates are grooved and covered over with filter cloths. The filtrate passes through the filter cloth and flows via the grooves in the plates into a collecting pipe. The filtrate exits the plate and frame filter press through the collecting pipe and is collected in the filtrate tank. The solid material is separated off at the filter cloth, where it forms a growing filter cake. As the filter cake becomes thicker, its flow resistance also increases. When the separating chamber is full, or a maximum pressure difference has been reached, the filtration process is ended. The plates and frames of the plate and frame filter press are pulled apart. The filter cake can be removed. For the next filtration, the plates and frames must be pushed back together. A spindle is used to press them together. The press forces ensure that the suspension does not leak from the contact points between the plates and the frames, but is forced through the filter cloth.

The flow rate through the plate and frame filter press is adjusted by a valve. The pressure occurring during filtration is indicated on a manometer. The filtrate tank is scaled. This means a stopwatch can be used to measure the flow rate.

An optional Opacimeter allows the solid concentration of the filtrate to be determined. A drying chamber is recommended for the evaluation of the experiments.

Specifications:

Plate and frame filter press for discontinuous cake filtration

HDPE tank to produce a suspension

Centrifugal pump to deliver the suspension to the plate and frame filter press

Plate and frame filter press with 10 opening separating chambers for removal of the filter cake

PMMA tank with level scale for filtrate

Adjustment of suspension flow rate by valve

Thermometer and manometer in an inlet

Optional Portable Opacimeter to measure the solid concentration in the filtrate

Technical Specifications:

Plate and frame filter press

Filter area: approx. 0,72m2

Working pressure: approx. 0,4…2,5bar

Centrifugal pump (submersible pump)

Max. flow rate: 4,5m3/h

Max. head: 45m

Tanks

Suspension tank: 200L

Filtrate: 20L

Measuring ranges

Pressure: 0…4bar

Temperature: 0…60°C

Experiments:

- Learning the fundamental principle and method of operation of a plate and frame filter press

- Production of a suspension

- Removal of the filter cake

- Insertion of the filter cloth

- Fundamentals of cake filtration

- Darcy’s equation

- Variation in time of filtrate quantity and solid concentration infiltrate

- Mass of filter cake dependent on filtrate quantity

Mains Power

? 220 – 240V 1Ph, 50Hz

91-9829132777

91-9829132777