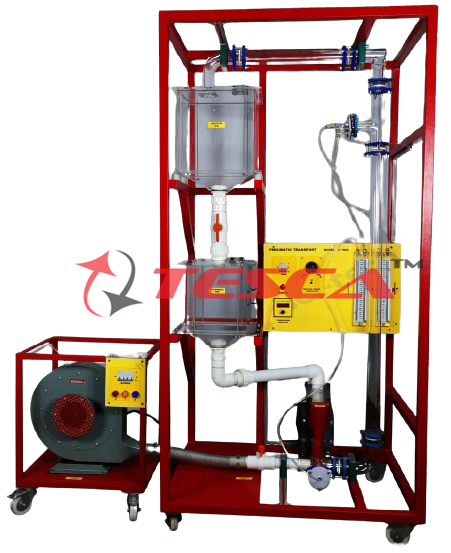

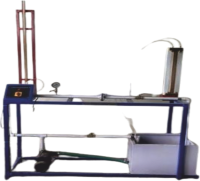

Pneumatic Transport Apparatus

Order Code: 32114

Category: Fluid Mechanics Lab

Features: Pneumatic pressure-lifting of solids in a vertical tube Transparent tubes and tanks to observe different transport states Practical experiments on a laboratory scale Tesca Pneumatic Conveyors/Tr...

SPECIFICATION

Features:

- Pneumatic pressure-lifting of solids in a vertical tube

- Transparent tubes and tanks to observe different transport states

- Practical experiments on a laboratory scale

Tesca Pneumatic Conveyors/Transport Apparatus can be used to transport dispersed solids over great distances in pipelines.

The solid is transported out of a feed tank via a vibrating trough into an airflow. An interchangeable injector disperses the solid in the airflow. The airflow transports the solid upwards in the tube. The transport terminates in a collector tank.

Depending on the velocity and solid content of the airflow, different transport states may occur. At high velocities, the solid is dispersed evenly across the cross-section of the tube (dilute phase transport). If the velocity is reduced, strands and balls form on the wall of the tube which then slide down owing to their higher settling velocity. The strands and balls disintegrate again in the airflow and reform. Reducing the velocity to below the settling velocity of the individual particles ultimately results in plug transport. The different transport states can be observed through the transparent tube.

To identify the pressure loss and the flow velocity, measuring points are provided at all relevant positions. The velocity of the airflow is adjusted by a pressure regulator. The solid mass flow can be adjusted by way of the throw of the vibrating trough on a potentiometer. The compressed air has to be provided from the laboratory supply.

Peas or plastic granulate are recommended for use as solid.

Specifications:

- Pneumatic pressure-lifting of solids in a vertical tube

- Feed of solid into airflow via vibrating trough with adjustable throw

- 4 interchangeable injectors to disperse the feed material into the airflow

- Vertical tube made of glass

- Collector and feed tanks made of transparent material (PMMA)

- Collector and feed tanks interconnected by tube with plug valve

- Precision pressure regulator to adjust input pressure and flow rate

- Measuring points for pressure loss, temperature, and flow velocity

Technical Specifications:

Vertical tube

Height: 2m

Diameter: 50mm

Tanks

Feed: 20L

Collector: 40L

Measuring ranges

Velocity (vertical tube): 0…36m/s

Differential pressure (vertical tube): 0…10kPa

Pressure (inlet): 0…1bar

Temperature: 0…60°C

Experiments:

- Learning the fundamental principle and method of operation of a pneumatic conveyor system

- Observation of different transport states dependent on solid content and air velocity

- Determination of the suspension velocity of the solid

- Determination of the solid content of the flow

- Pressure loss dependent on solid content and air velocity

Requirements:

Mains Power 220 – 240V @ 50Hz, 1Ph

91-9829132777

91-9829132777