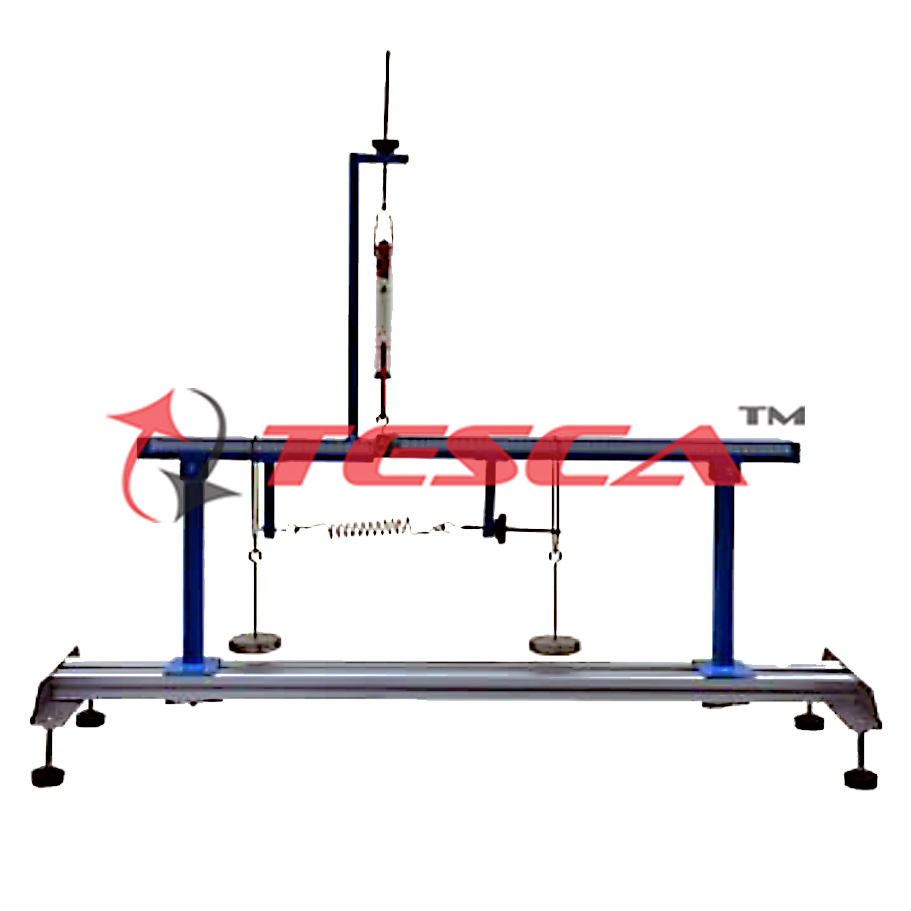

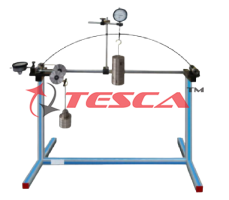

Shear Force Apparatus

Order Code: 32195

Category: Strength of Materials Lab

Features Bench mounted Direct measurement of Shear Force Loads and supports can be placed in any position Visual practical verification of the concept of Shear Force Allows investigation of stability and influence lines Reinforces concept of eq...

SPECIFICATION

Features

Bench mounted

Direct measurement of Shear Force

Loads and supports can be placed in any position

Visual practical verification of the concept of Shear Force

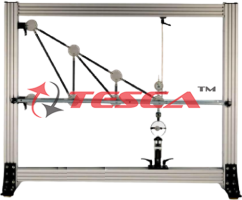

Allows investigation of stability and influence lines

Reinforces concept of equilibrium of vertical forces & moments

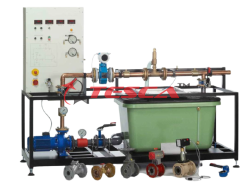

Optional DAQ with ‘LabView’ interface

A length of material supported horizontally and carrying vertical loads is called a beam. The loading causes bending and transverse shearing. The loads and reactions are the 'external' forces acting on the beam. They must be in equilibrium. However, the strength of the beam depends on 'internal' forces. This experiment demonstrates the nature of these internal forces and their dependence on the external system of forces.

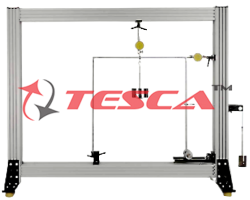

In the Tesca Shear Force Apparatus, the experimental beam is in two parts, joined by a pair of ball bearing rollers running in flat vertical tracks. To develop the internal beam forces at the section an under slung tension spring is used to resist the bending moment, while an overhung spring balance provides the vertical shearing force. Due to the mechanical arrangement, there must always be a net downward load on the longer side of the split beam. The beam is simply supported on end bearings and several weight hangers can be attached at any position on either side of the joint. A hinged metal strip is available to simulate the loading pattern of a paneled girder for a more advanced experiment on influence lines.

This equipment is part of a range designed to both demonstrate and experimentally confirm basic engineering principles. Great care has been given to each item so as to provide wide experimental scope without unduly complicating or compromising the design. Each piece of apparatus is self contained and compact. Setting up time is minimal, and all measurements are made with the simplest possible instrumentation, so that the student involvement is purely with the engineering principles being taught.

Optionally, computer interface & sensors to DAQ software with ‘LabView’ offered. A complete instruction manual is provided describing the apparatus, its application, experimental procedure and typical test results.

Specifications

To perform a range of experiments designed to both demonstrate and experimentally confirm basic engineering principles

To observe the action of shear force at a section in a beam and to compare the measured and theoretical values

To comprehend the action of shear and moment of resistance in a beam

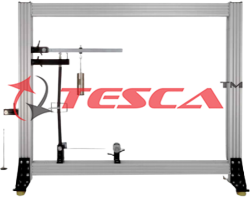

To consist of 2 simple supports; a rigid aluminum alloy beam cut into two unequal

lengths, with a frictionless hinge at the joint which permits minimal vertical movement, whilst allowing bending

Analogue spring balance measures direct force at the ‘cut’ section

Multiple load positions achievable

To be bench top mounted

Set of slotted weights included

Technical Specifications

1. Overall length: 1000mm

2. Test Span variable

3. Cross section of beam: 50mmx25mm

4. Height of support: 300mm

5. Cut section: 350mm from support

6. Electronic Force Gauge

7. Horizontal force: 150mm from centre pin

8. Force Gauge capacity: 200N

9. Digital Force Gauge indicator: 0.1N resolution

10. Able to load beam at any location.

11. 3 nos, load hangers

12. 10 nos, 10N weights

Optional

Usable on ‘Tesca mounting Frame 32150

Data acquisition DAQ software, through USB available in ‘LabView’

Experiments

1. To comprehend the action of shear in a beam

2. To measure the shearing force at a section of a loaded beam, and to compare with a theoretical estimate

3. To study the definition of an influence line for shear force

91-9829132777

91-9829132777